Method for preparing biological oil through vacuum pyrolysis of biomasses

A biomass and bio-oil technology, which is used in the preparation of liquid hydrocarbon mixtures, biofuels, and petroleum industries, can solve the problems of difficult separation of cracked oil, increase the heat transfer efficiency of the reactor, and improve the condensation effect and ease the energy shortage. , the effect of reducing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

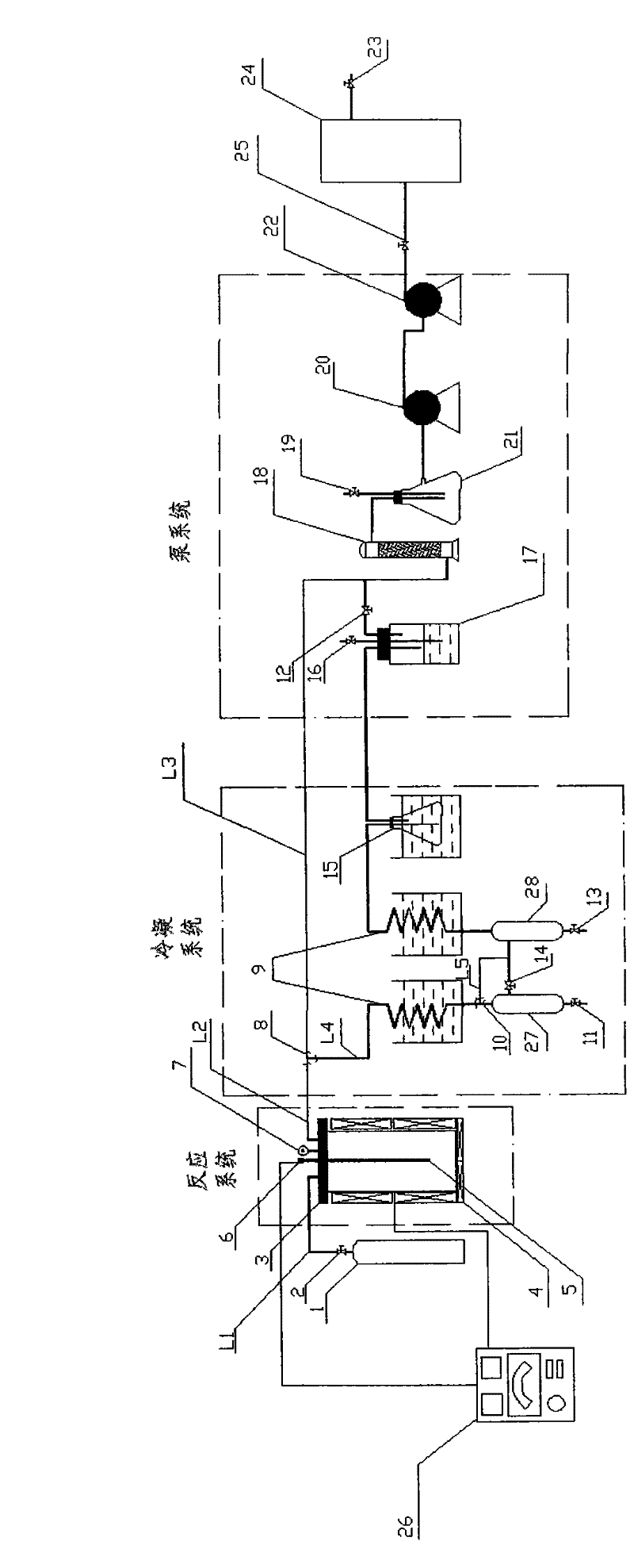

[0027] Such as figure 1 As shown, the plant diagram of the inventive method includes an interconnected reaction system, a condensation system and a pump system. The reaction system includes a stainless steel reaction kettle 3, a tube furnace 4, and a temperature controller 26. There are interfaces on the flange surface of the reaction kettle, which are respectively connected to the vacuum gauge 7, the blind pipe 5, the first branch L1 and the second branch L2 , The reaction kettle condensation system includes three-stage condensation. The first two-stage condensation tanks are respectively equipped with water and ice-water mixtures. The condensation tank and the stainless steel elbow are welded as one. 9. A collector is connected to the outlet of the stainless steel elbow. The third-stage condensation The tank is ice-salt mixture. The pump system includes an absorber 17 , a drying tower 18 , a buffer bottle 21 , a vacuum pump 20 and a compression pump 22 . A three-way valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com