Preprocessing method of neopentyl glycol production wastewater

A technology for the production of wastewater and neopentyl glycol, which is applied in natural water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve problems such as no economical and effective treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

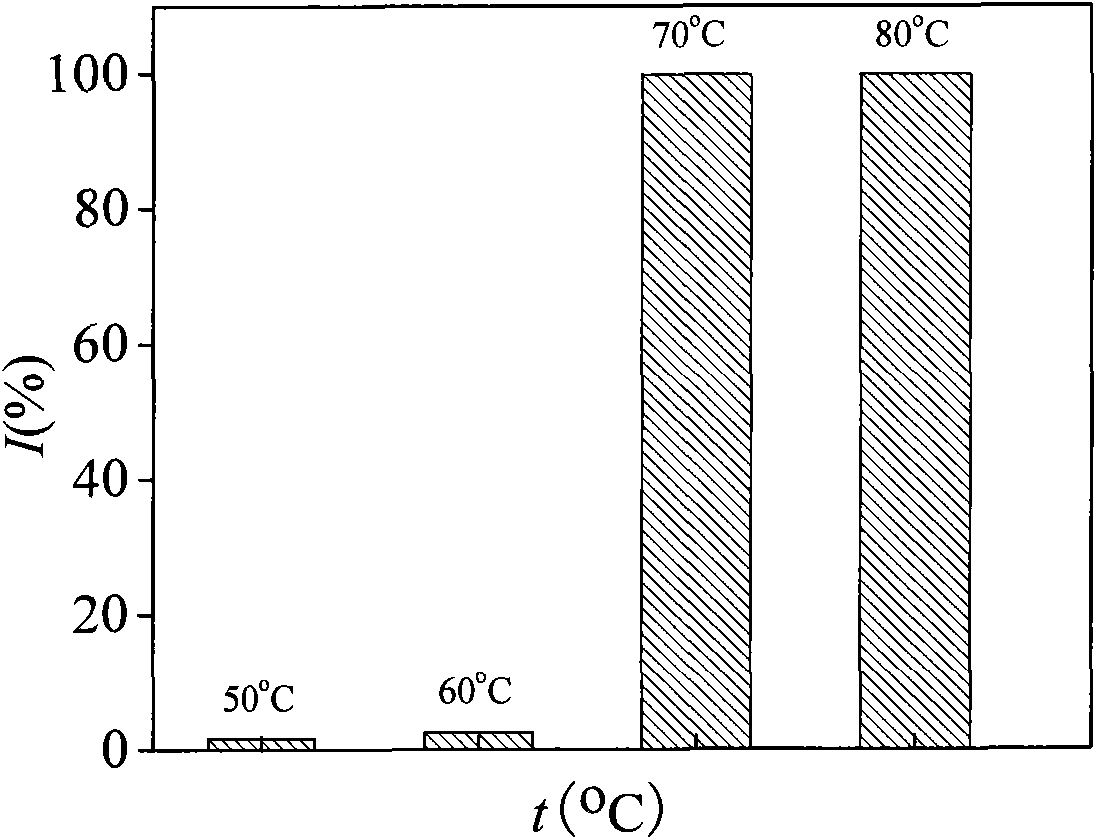

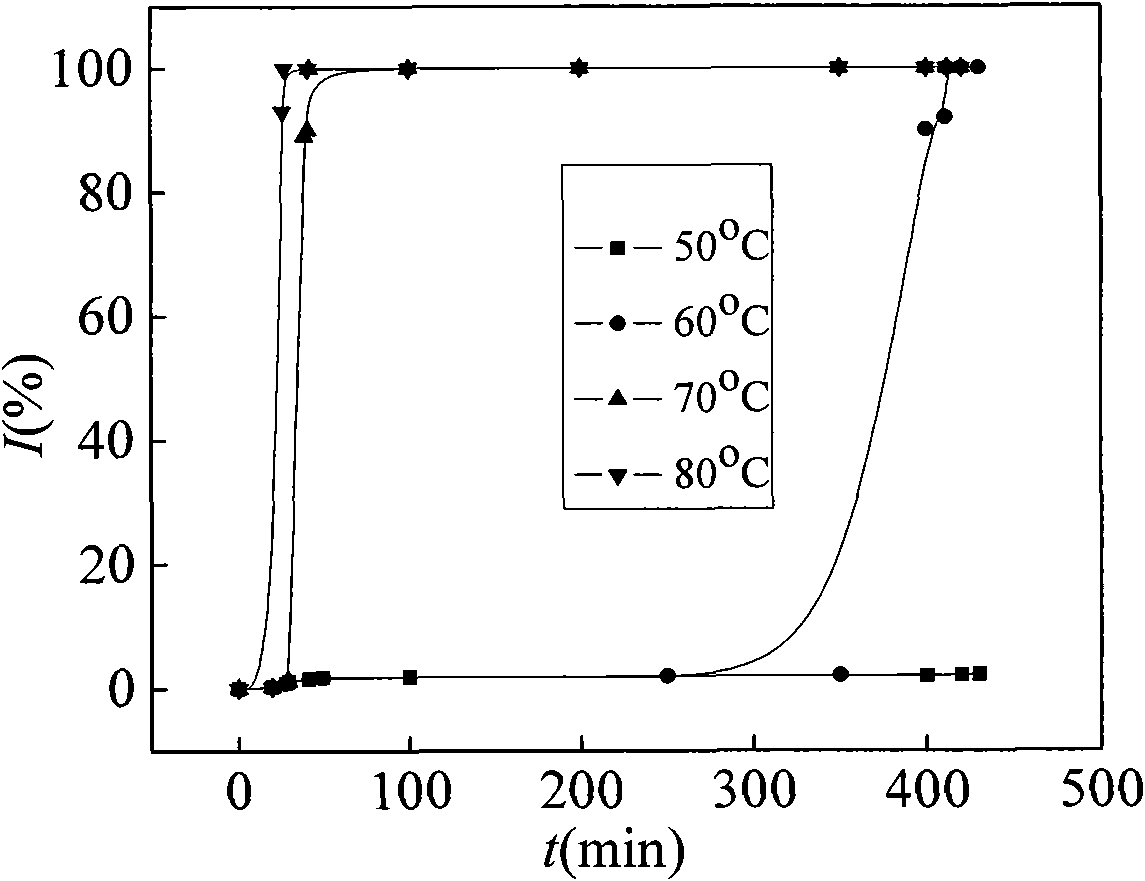

[0040] Take 100mL of 300mg / L simulated formaldehyde waste water in an Erlenmeyer flask, add 0.28g of calcium oxide according to the calcium oxide / formaldehyde molar ratio of 5:1, and control the reaction temperature to 70°C under the vibration condition of 150r / min. Changes in formaldehyde concentration.

[0041] The current treatment effect is: under the condition of 70°C, when the reaction time is 60 minutes, the formaldehyde removal rate is 99.8%, and the formaldehyde concentration after treatment is 0.65mg / L, which is lower than the maximum allowable formaldehyde emission stipulated in the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" concentration limit.

Embodiment 2

[0043] Take 100mL of 500mg / L simulated formaldehyde waste water in a conical flask, add 0.187g of calcium oxide according to the calcium oxide / formaldehyde molar ratio of 2:1, and control the reaction temperature at 70°C under the vibration condition of a rotating speed of 150r / min. The concentration of formaldehyde varies with time.

[0044] The current treatment effect is: under the condition of 70°C, the removal rate of formaldehyde rises rapidly to nearly 90% in the vicinity of 40 minutes. When the reaction time is 50 minutes, the formaldehyde concentration is 0.73mg / L, and the pretreatment effect can be achieved in a short period of time.

Embodiment 3

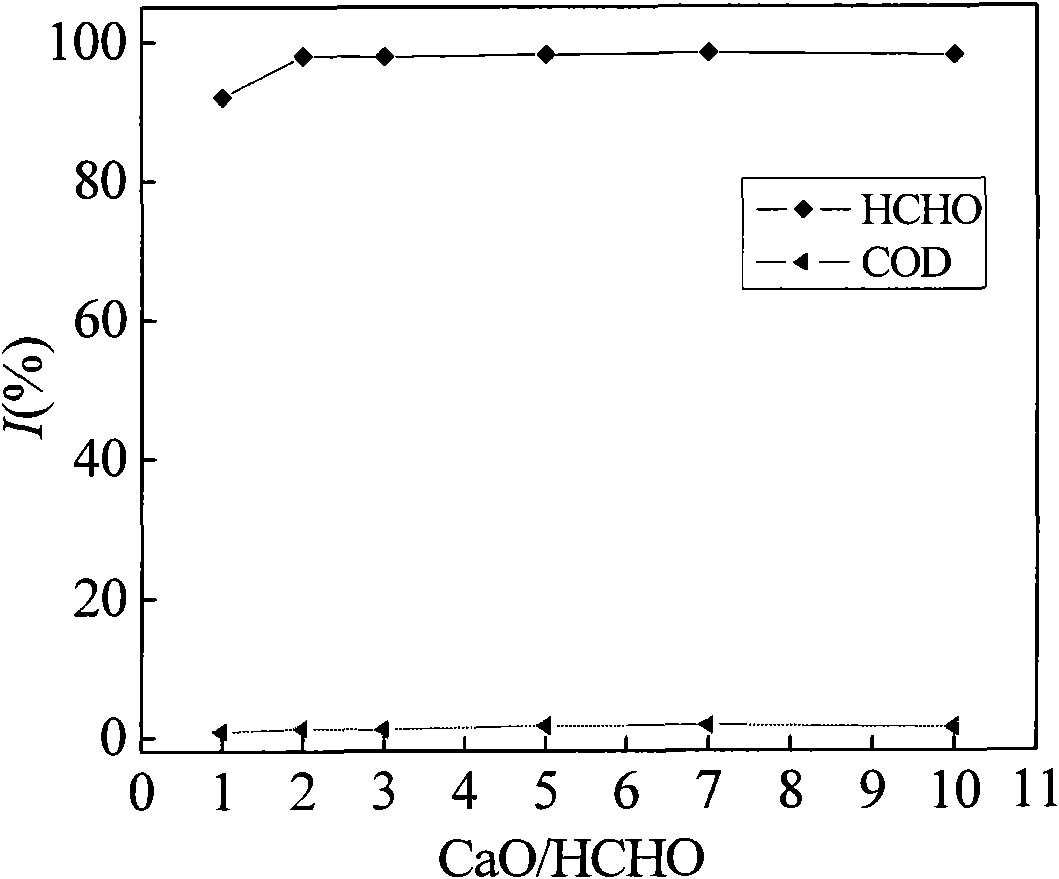

[0046] Take 100mL of representative neopentyl glycol production wastewater (formaldehyde concentration is about 310mg / L) in an Erlenmeyer flask, under the vibration condition of 150r / min, control the reaction temperature at 70°C, according to the calcium oxide / formaldehyde molar ratio Add 0.158g of calcium oxide at a ratio of 5:1, measure formaldehyde concentration, CODcr and SS after a reaction time of 60min.

[0047] The current treatment effect is: at a reaction temperature of 70°C, when the molar ratio of calcium oxide / formaldehyde is 5:1, the removal rate of formaldehyde within 60 minutes is close to 99.9%, and the concentration of formaldehyde after pretreatment is 0.37mg / L; There is no obvious change in the process. The pretreatment of neopentyl glycol by calcium oxide alkaline catalyzed polymerization only changes the form of formaldehyde and does not completely remove it. However, after pretreatment, neopentyl glycol production wastewater can relieve the toxicity inhib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com