Dedusting system of whole factory building

A technology for dust removal systems and workshops, used in air conditioning systems, ventilation systems, and household heating, etc., can solve the problems of large air supply, inability to effectively avoid welding smoke passing through the human breathing zone, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

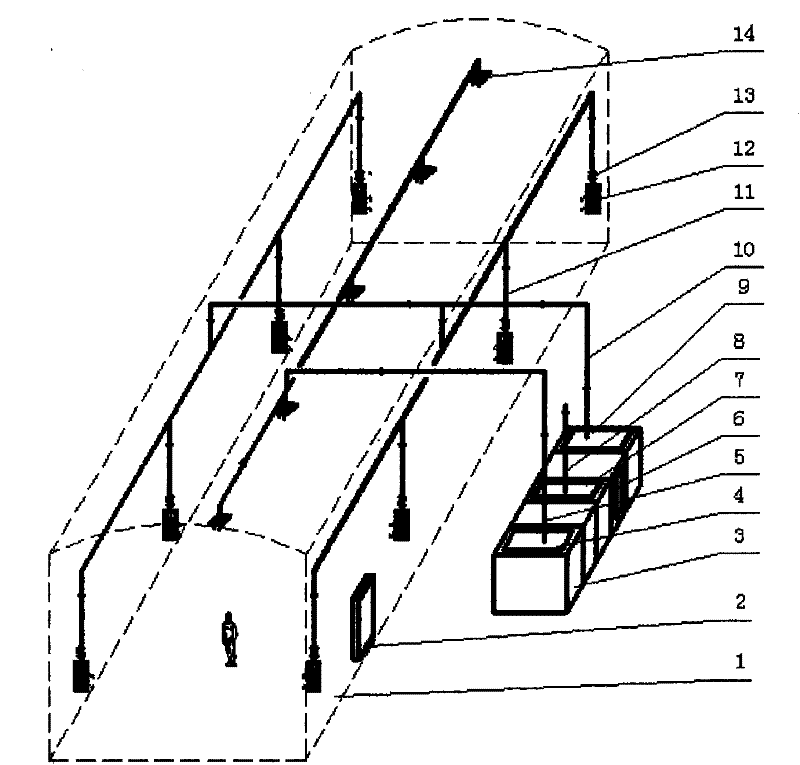

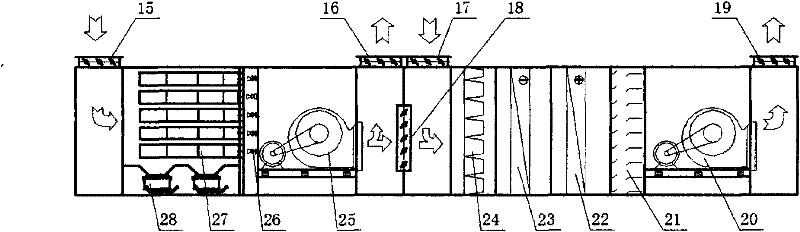

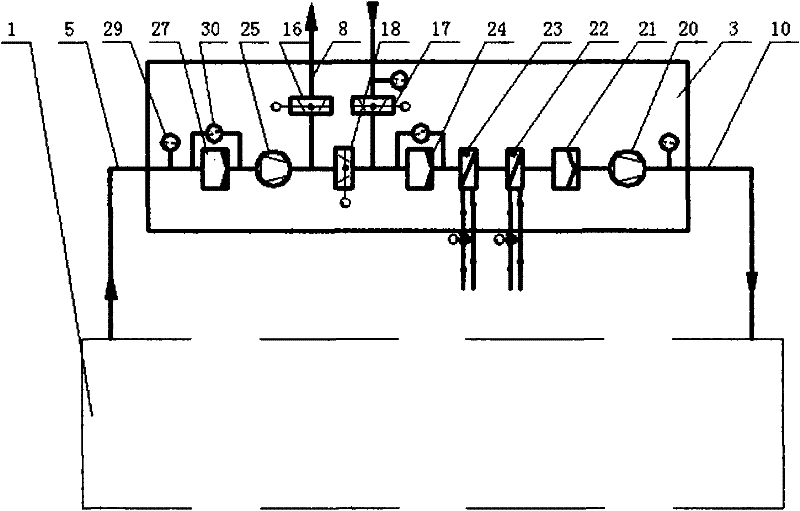

[0014] see figure 1 , figure 2 , image 3 , 1-workshop, 2-control system, 3-combined air handling unit, 4-return air outlet, 5-return air supervisor, 6-fresh air outlet, 7-exhaust air outlet, 8-exhaust air pipe, 9-air supply outlet , 10-air supply main pipe, 11-air supply branch pipe, 12-air supply cylinder, 13-air supply balance regulating valve, 14-top return air outlet, 15-return air valve, 16-exhaust air valve, 17-fresh air valve, 18-air mixing valve, 19-air supply valve, 20-blower and motor, 21-low temperature plasma purifier, 22-heater, 23-surface cooler, 24-primary filter, 25-return fan and motor, 26-Blowback solenoid valve, 27-Filter cartridge, 28-Ash hopper, 29-Temperature and humidity sensor, 30-Pressure difference sensor.

[0015] The dust removal system for the overall factory building includes an air supply tube 12, an air handling unit 3, an air return port 4, a top air return port 14, an air supply duct 10, and an air return duct 5. The air handling unit 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com