Method for processing wastewater in production of nickel cobalt lithium manganate

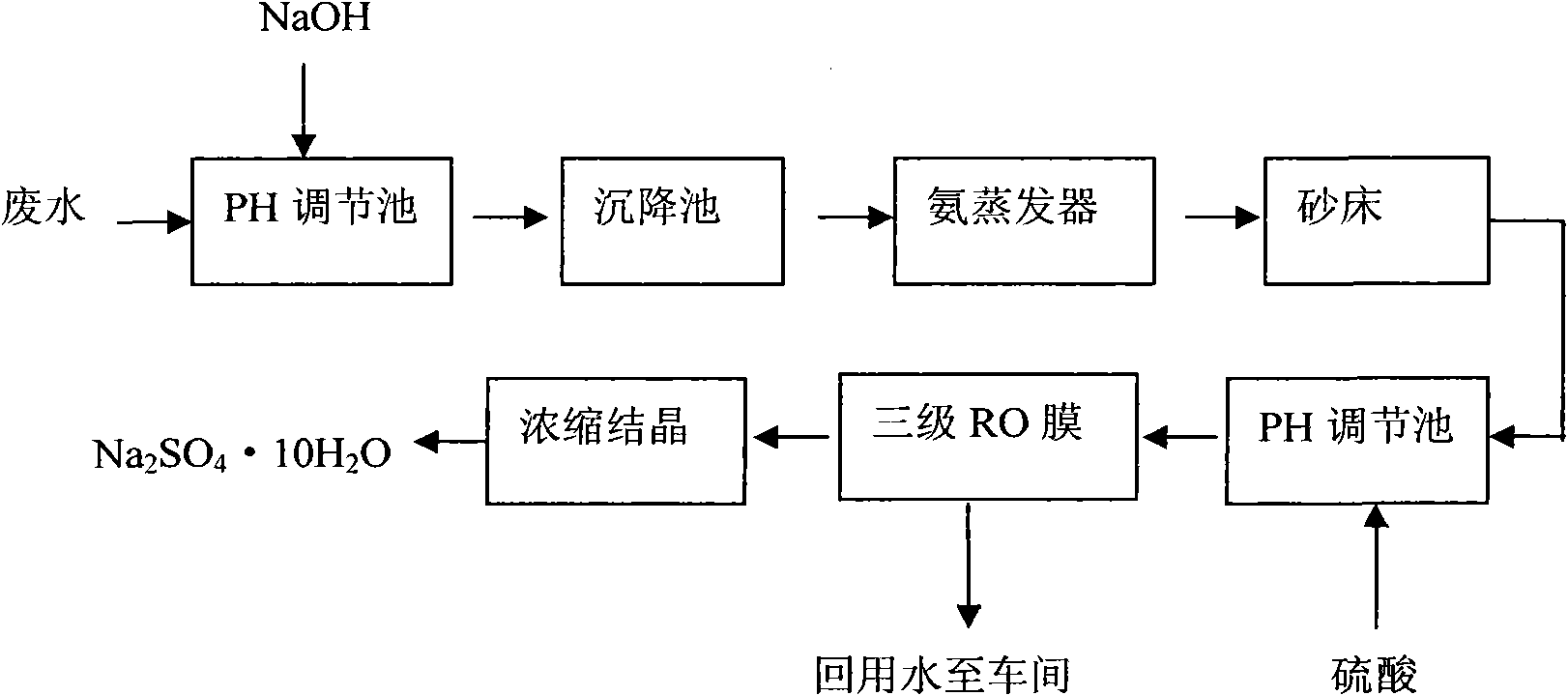

A nickel-cobalt lithium manganese oxide and wastewater production technology, which is applied in the field of energy saving and emission reduction, can solve the problems of large wastewater, and achieve the effects of zero discharge, high reuse rate, and large industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0028] Taking 10 tons of wastewater produced by producing 1 ton of nickel-cobalt lithium manganate precursor as an example, the quality of the wastewater is:

[0029] serial number

[0030] By adding NaOH to the above wastewater to pH > 12.5, the Ni 2+ The ion concentration is reduced to 1-5mg / L, Mn 2+ 、Co 2+ The ion concentration is reduced to 2+ , Mn 2+ 、Co 2+ The ion concentration is reduced to + , SO 4 2- ions, after the three-stage RO membrane, the recovery rate of pure water is as high as 80%, and concentrated water can be concentrated and crystallized to obtain 4 tons of Na 2 SO 4 10H 2 O or 1.75 tons of Na 2 SO 4 The by-products achieve an economic value of about 5,000 yuan, and the entire treatment process achieves zero emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com