Ester exchange reaction method and device thereof in production of biodiesel

A technology of transesterification and biodiesel, which is applied in the direction of biological raw materials, biofuels, petroleum industry, etc., can solve the problems of high energy consumption and investment, difficulty in realization, high alcohol/oil ratio of reactor feed, and reduce infrastructure investment , Reduce production cost, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

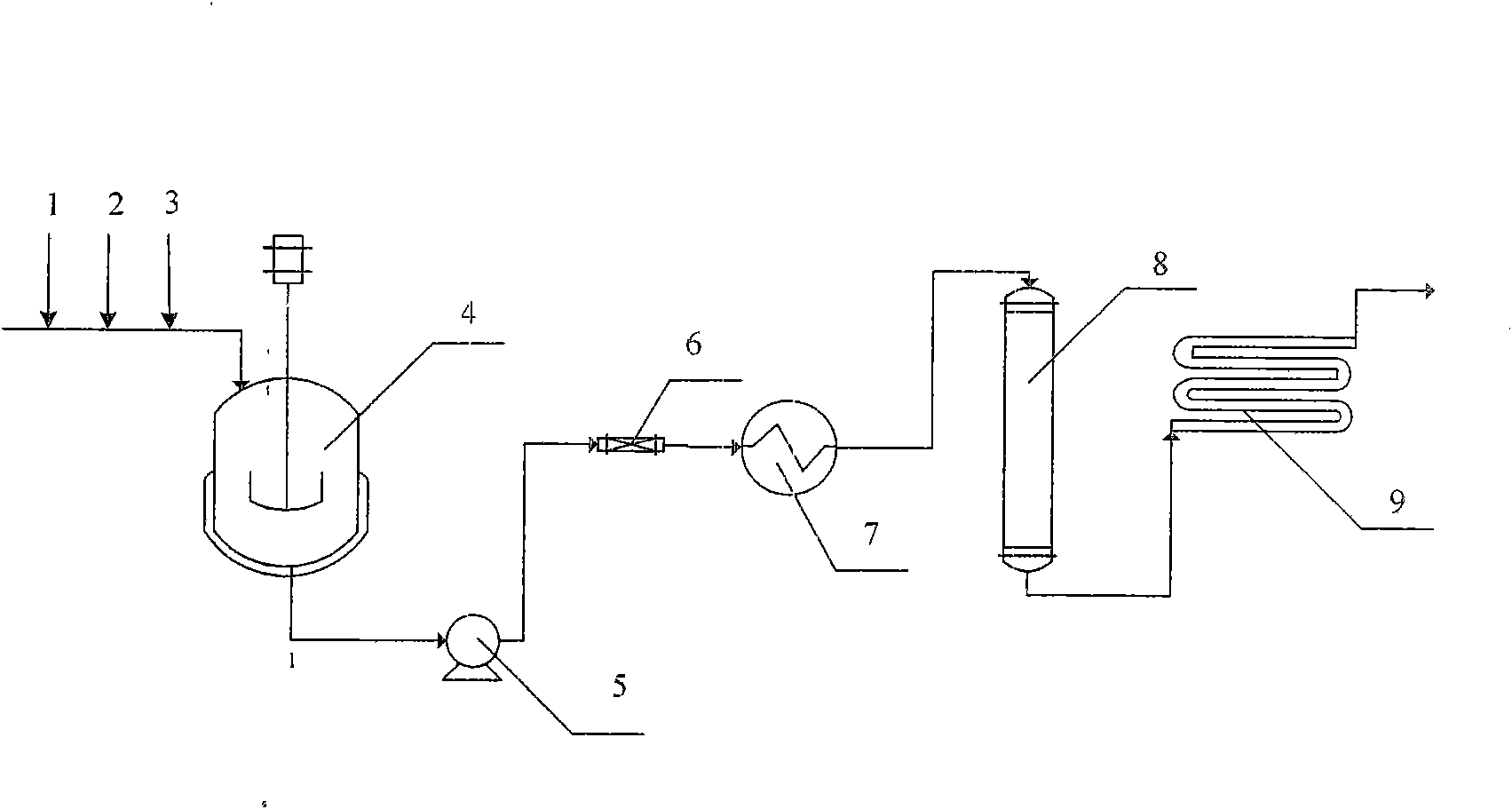

[0031] Oil plant: the animal fat of acid value 1.2mgKOH / g does not need pre-esterification, and methanol is continuously added to the mixing tank 4 with a molar ratio of 1: 5, and the catalyst NaOH and methanol solution of 5% concentration are mixed with 0.05% (to the oil plant) The amount is added continuously. The pressure in the mixing tank 4 is 0.5-1.0Mpa, set the stirring at 120rpm, heat up to 65°C under stirring, fully mix the immiscible reactants with the catalyst NaOH solution, stay for 20min, leave the mixing tank 4, and go through static mixing The reactor 6 is continuously metered and transported by the feed pump 5 for the transesterification reaction, passes through the raw material preheater 7, and enters the combined transesterification reactor 8. The reaction material is heated by a heat carrier to reach a reaction temperature of 240°C, and then enters the continuation reactor 9 of three groups. The continuation reactor 9 is a pipe reactor with variable diameter...

Embodiment 2

[0034] Rancid rapeseed oil, acid value 12mgKOH / g, use common liquid sulfuric acid to carry out pre-esterification and alkali washing, after water washing, acid value is reduced to 1mgKOH / g, then carry out transesterification, reaction equipment, reaction conditions are all with embodiment 1 Same: add methanol and methanol in a molar ratio of 1:5 to the mixing tank continuously, and add 5% NaOH and methanol solution in an amount of 0.05% (to oil) continuously. The mixing tank is set with 120rpm stirring, and the temperature is raised to 65°C under stirring to fully mix the immiscible reactants with the catalyst, and stay for 20 minutes. After leaving the mixing tank, it passes through the static mixer 6 and is continuously metered by the transesterification feed pump 5 The material is conveyed through the raw material preheater 7 and enters the combined transesterification reactor 8. The reaction material is heated up to a reaction temperature of 240°C by heat carrier, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com