Method for preparing high-purity stachyose by using plant chromatographic separation technology

A technology of industrial chromatography and separation technology, applied in the field of stachyose preparation, which can solve the problems of low purity of polysaccharides, limited audience and application fields, low functionality, etc., achieve high yield, increase farmers' income, and reduce losses low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

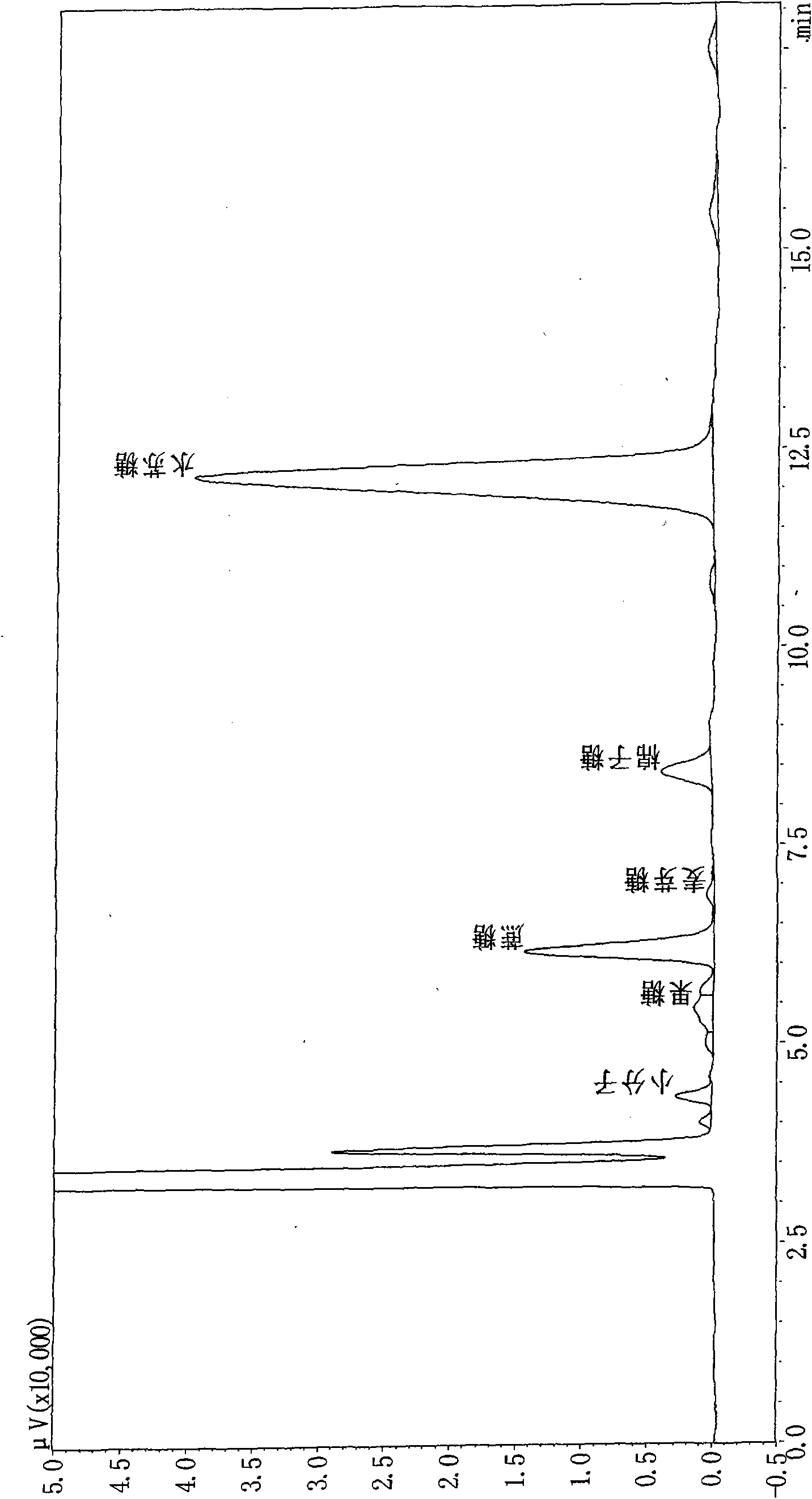

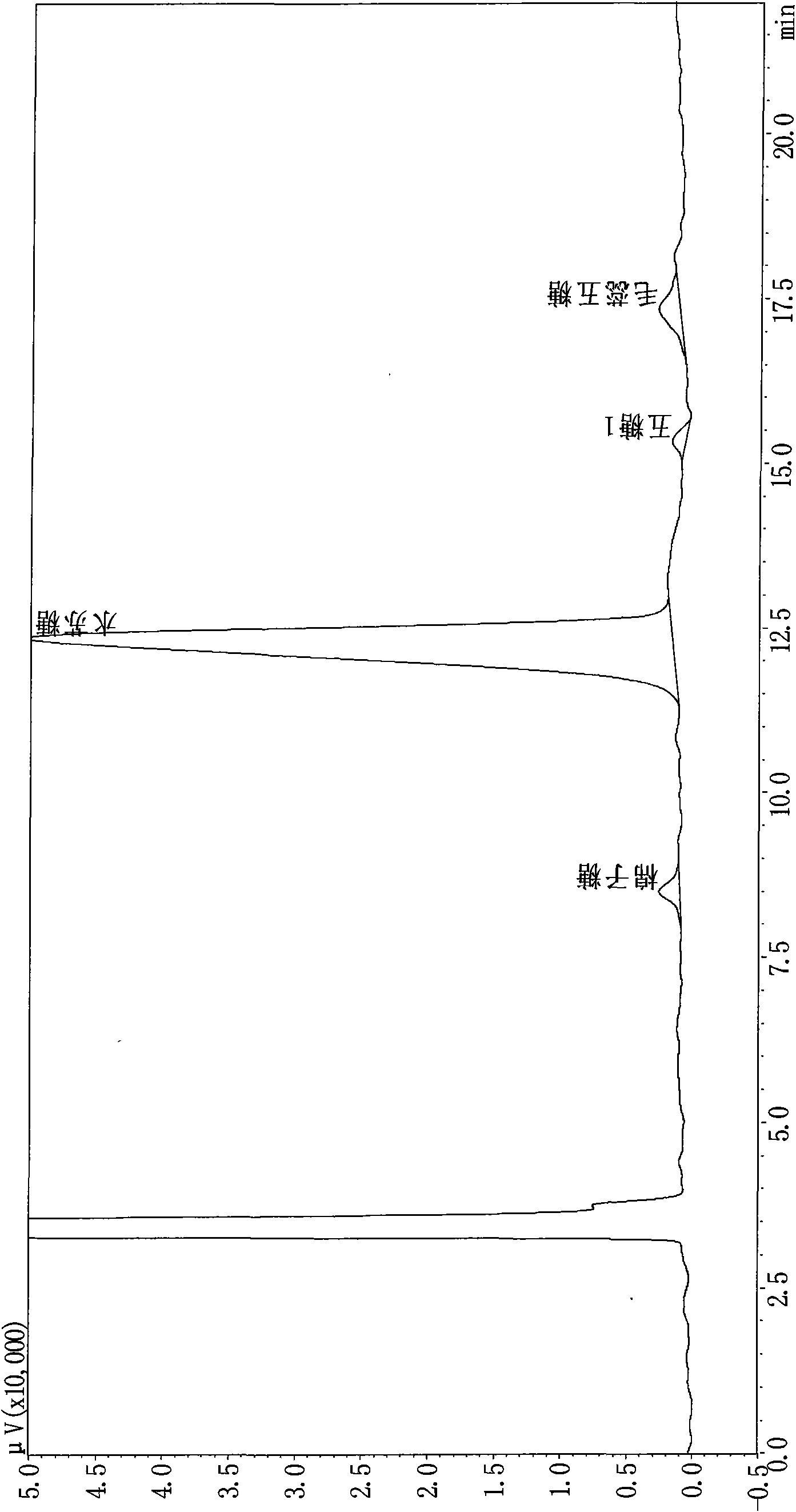

Image

Examples

Embodiment 1

[0033] (1) Juicing: choose 10kg of non-mildew hay caddis, wash it, add 40L of water at 80°C for 1 hour, extract the residue and add water twice the weight of the residue at 80°C for 1 hour, and mix. The juice squeezed twice is used as sugar solution;

[0034] (2) Impurity removal: heat up the sugar solution to 90° C., heat for 20 minutes, filter, remove the precipitate, add clarifier sodium hydroxide to the filtrate at a ratio of 6 g: 1 L, let stand for precipitation for 60 minutes, and take supernatant;

[0035] (3) Decolorization: according to the ratio of 1L: 6g, add activated carbon to the supernatant, heat to 90°C, decolorize for 40 minutes, and filter to remove the activated carbon;

[0036] (4) Desalination: the decolorized liquid is cooled to 25°C, and the conductivity is reduced to below 50 μs / cm through cation exchange resin, anion exchange resin, cation exchange resin, and anion exchange resin in sequence;

[0037] (5) Membrane filtration: filter the desalted liqu...

Embodiment 2

[0042] A method for preparing high-purity stachyose with industrial chromatographic separation technology, comprising the steps of:

[0043] (1) Juicing: According to the ratio of mass ratio of 1:4, add water to the dry caddis worm and extract at 70°C for 1.0 hour, squeeze the juice, take the residue, add water twice the mass of the residue and extract at 70°C for 1.0 hour Re-squeezing, mixing the squeezed juice twice to make sugar liquid;

[0044] (2) Impurity removal: the sugar solution was heated to 80° C., heated for 20 minutes, filtered, and the precipitate was removed. The clarifier sodium hydroxide was added to the filtrate at a ratio of 8 g: 1 L, and allowed to settle for 60 minutes. supernatant;

[0045] (3) According to the ratio of 1L: 7g, add activated carbon to the supernatant, heat to 80°C, decolorize for 50 minutes, and filter to remove the activated carbon;

[0046] (4) Desalination: The decolorized liquid is lowered to 20°C, and the conductivity is reduced t...

Embodiment 3

[0052] A method for preparing high-purity stachyose with industrial chromatographic separation technology, comprising the steps of:

[0053] (1) Juicing: According to the ratio of mass ratio of 1:3, add water to the dry silver white strips and extract at 50°C for 1.5 hours, squeeze the juice, take the residue, add water 1 times the mass of the residue, and extract at 50°C for 1.5 hours. Squeeze, mix twice squeezed juice to be sugar liquid;

[0054] (2) Impurity removal: the sugar solution was heated to 50° C., heated for 30 minutes, filtered, and the precipitate was removed. The clarifying agent sodium hydroxide was added to the filtrate at a ratio of 5 g: 1 L, and allowed to settle for 90 minutes. supernatant;

[0055] (3) Decolorization: according to the ratio of 1L: 4g, add activated carbon to the supernatant, heat to 60°C, decolorize for 60 minutes, and filter to remove the activated carbon;

[0056] (4) Desalination: The decolorized liquid is lowered to 30°C, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com