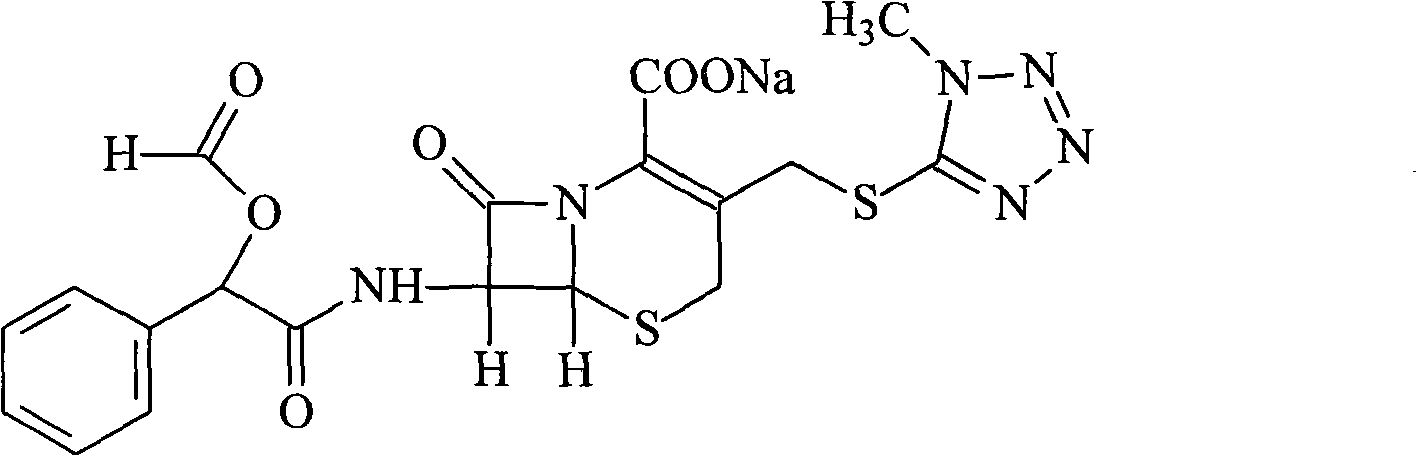

Suspension powder injection of cefamandole nafate and new application thereof

A technology of cefamandole sodium and cefamandole sodium, which is applied in the directions of powder delivery, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., can solve the problem of poor stability and stable problems such as poor performance, to achieve the effects of low cost, improved bioavailability, increased safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

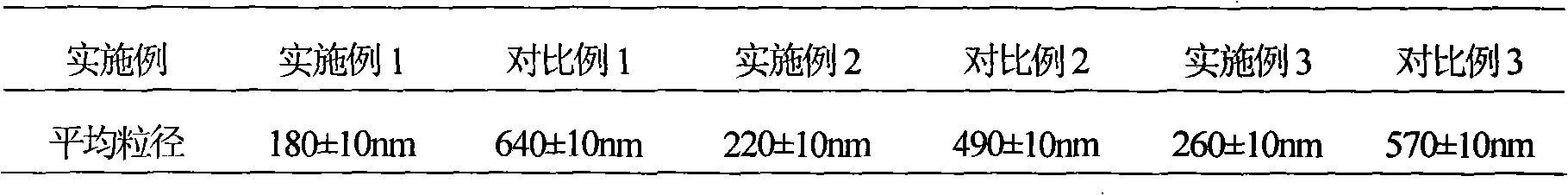

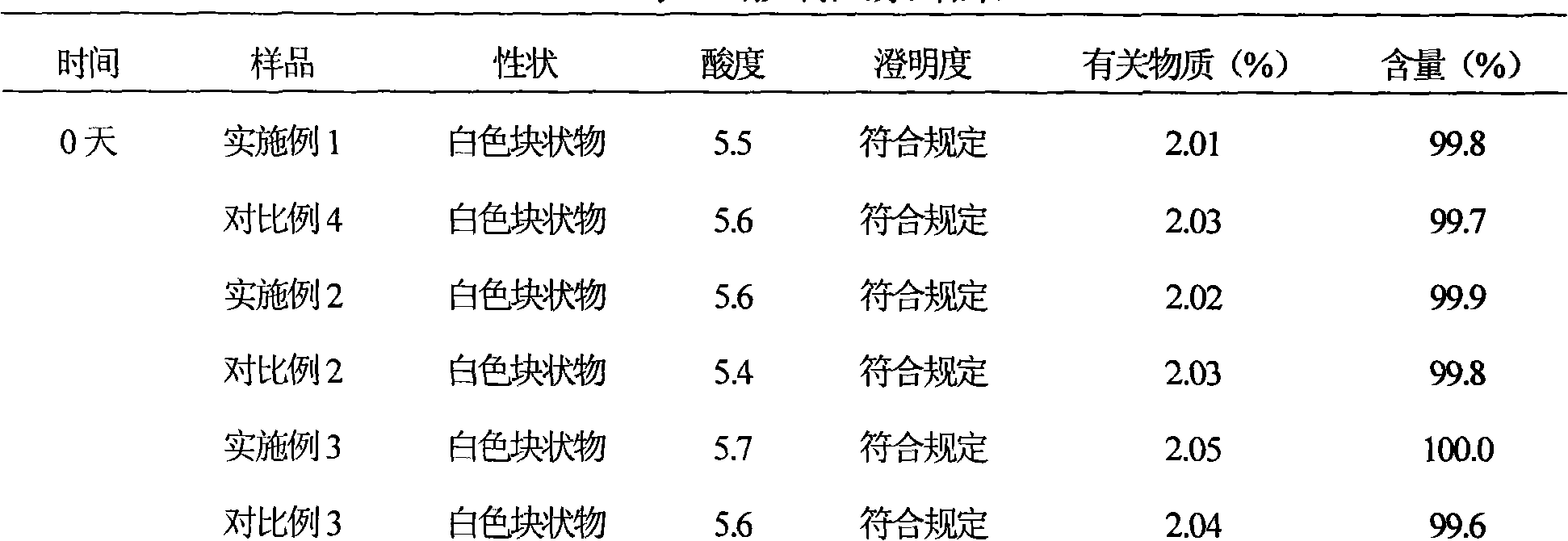

Embodiment 1

[0034] The preparation of embodiment 1 cefamandole sodium suspension powder injection

[0035] Prescription (100 bottles):

[0036] Cefamandole Sodium 50g

[0037] Cholesterol 83.3g

[0038] Poloxamer 188 41.7g

[0039]Mannitol 75g

[0040] Sorbitol 75g

[0041] Preparation Process

[0042] (1) Add 83.3g of cholesterol and 41.7g of poloxamer 188 into 1000ml of water for injection, then add 50g of cefamandole sodium and mix evenly, heat and stir in a water bath at 80°C until it melts;

[0043] (2) Heat the above liquid at 70-90°C and use a tissue masher to shear and stir for 15 minutes at a speed of 12000r / min to obtain a primary emulsion, and then circulate and emulsify it through a high-pressure homogenizer for 5 times to obtain an emulsion;

[0044] (3) Add 75g of mannitol and 75g of sorbitol into the emulsion, filter and subpackage after dissolving, and freeze-dry to obtain cefamandole sodium suspension powder injection.

Embodiment 2

[0053] The preparation of embodiment 2 cefamandole sodium suspension powder injection

[0054] Prescription (100 bottles):

[0055] Cefamandole Sodium 100g

[0056] Cholesterol 333.3g

[0057] Poloxamer 188 166.7g

[0058] Glucose 175g

[0059] Glycine 525g

[0060] Preparation Process

[0061] (1) Add 333.3g of cholesterol and 166.7g of poloxamer 188 into 6500ml of water for injection, then add 100g of cefamandole sodium and mix evenly, heat and stir in a water bath at 70°C until it melts;

[0062] (2) Keeping the above liquid at 70-90°C for 20 minutes with a tissue masher to shear and stir at a speed of 10,000 r / min to obtain a primary emulsion, and then circulate and emulsify it through a high-pressure homogenizer for 4 times to obtain an emulsion;

[0063] (3) Add 175g of glucose and 525g of glycine to the emulsion, filter and subpackage after dissolving, and freeze-dry to obtain cefamandole sodium suspension powder injection.

Embodiment 3

[0072] The preparation of embodiment 3 cefamandole sodium suspension powder injection

[0073] Prescription (100 bottles):

[0074] Cefamandole Sodium 200g

[0075] Cholesterol 600g

[0076] Poloxamer 188 300g

[0077] Trehalose 100g

[0078] Lactose 500g

[0079] Preparation Process

[0080] (1) Add 600g of cholesterol and 300g of poloxamer 188 into 7000ml of water for injection, then add 200g of cefamandole sodium and mix evenly, heat and stir in a water bath at 90°C until molten;

[0081] (2) Keeping the above liquid at 70-90°C for 20 minutes with a tissue masher to shear and stir at a speed of 15000r / min to obtain a primary emulsion, and then circulate and emulsify it through a high-pressure homogenizer for 5 times to obtain an emulsion;

[0082] (3) Add 100g trehalose and 500g lactose to the emulsion, dissolve, filter, subpackage, and freeze-dry to obtain cefamandole sodium suspension powder injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com