Treatment method and device for waste gas containing nitrogen oxides

A technology of nitrogen oxides and treatment methods, which is applied in the field of air pollution control, can solve the problems of difficult wide application, failure to meet emission requirements, high operating costs, etc., and achieve strong market competitiveness and good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

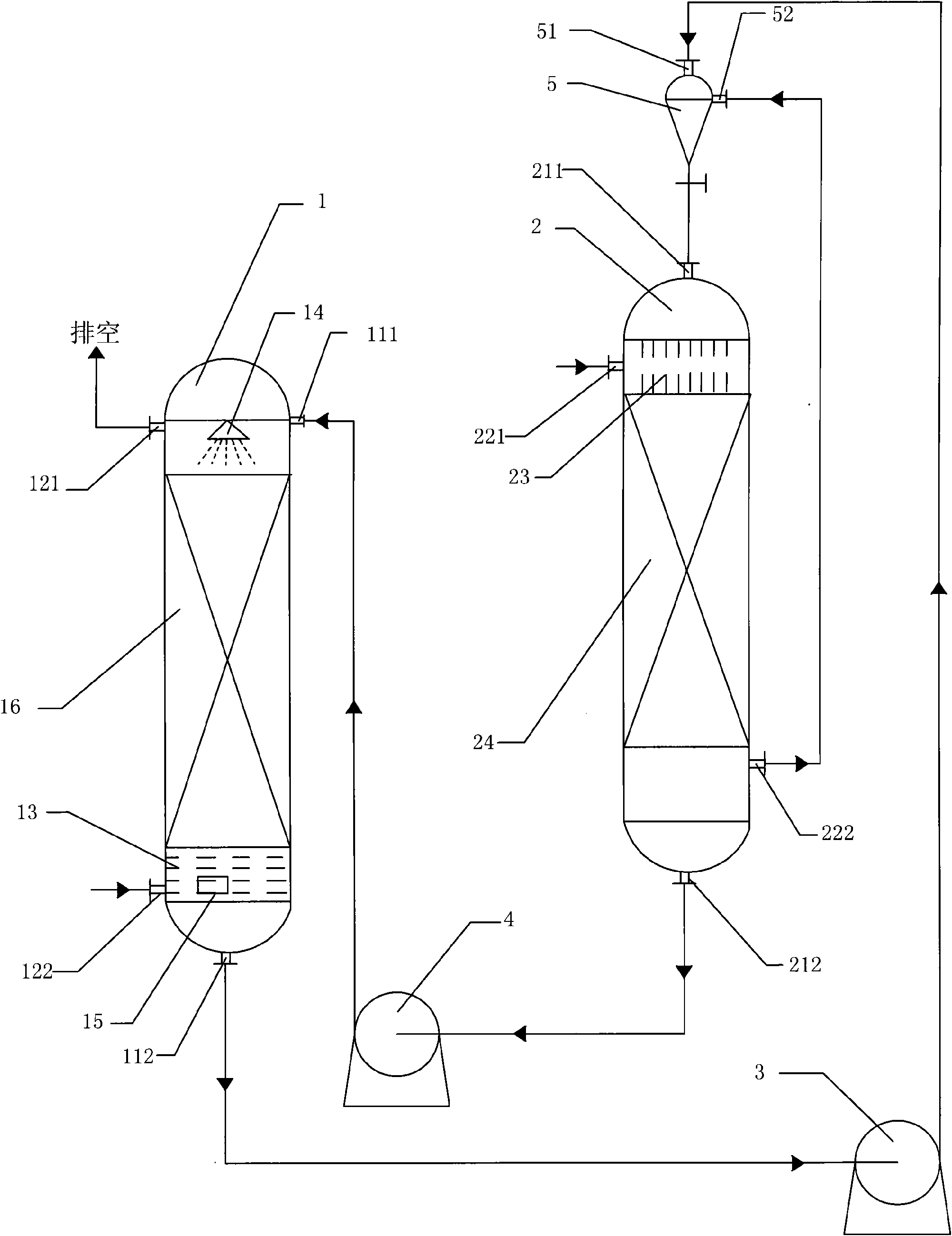

[0053] Such as figure 1 As shown, the absorption tower 1, the first circulation pump 3, the oxidation reaction tower 2 and the second circulation pump 4 are connected sequentially in the flow process through pipelines, wherein,

[0054] The top of absorption tower 1 is provided with liquid inlet 111 and exhaust port 121, and the middle part of absorption tower 1 is provided with packing 16 (or tray), and the below of packing 16 (or tray) is provided with the absorber that is used to store ferrous solution. Chamber 13, the bottom of absorption tower 1 is provided with nitrogen oxide waste gas inlet 122, and inlet 122 is positioned at the tower body part of absorption chamber 13, and the bottom of absorption tower 1 is provided with drain port 112, and drain port 112 passes through The pipeline is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com