Pretreatment liquid of organic weldable protective agent preparation method

A pretreatment liquid and organic solderable technology, applied in the field of electronic chemicals, can solve problems affecting the appearance of OSP boards, hidden dangers of OSP performance, troubles for PCB manufacturers, etc., to improve charge characteristics and reactivity, improve compactness and hydrophobicity , to ensure the effect of normal operation

Active Publication Date: 2010-02-03

GUANGDONG TONESET SCI & TECH

View PDF3 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, in the process of using the products of OSP suppliers at home and abroad, most of them have defects such as slow film formation speed, loose film structure, and poor oxidation resistance, which are prone to oxidative discoloration in the subsequent high-temperature assembly process and lead to poor soldering. Return incidents occur frequently, causing economic losses to many parties

Some suppliers increase the film forming speed by adjusting parameters, but the consequences of this are often due to the high activity of the OSP liquid, and the film components are not only deposited on the copper surface, but also on the row rollers, rollers and inner walls of the cylinder of the production line. Over time, a large number of hard-to-clean crystals have accumulated, which not only affects the appearance of the OSP board, but also has a great hidden danger to the performance of the OSP

If the situation is serious, it may even make it impossible to continue the production of PCB, which brings great troubles to PCB manufacturers.

Method used

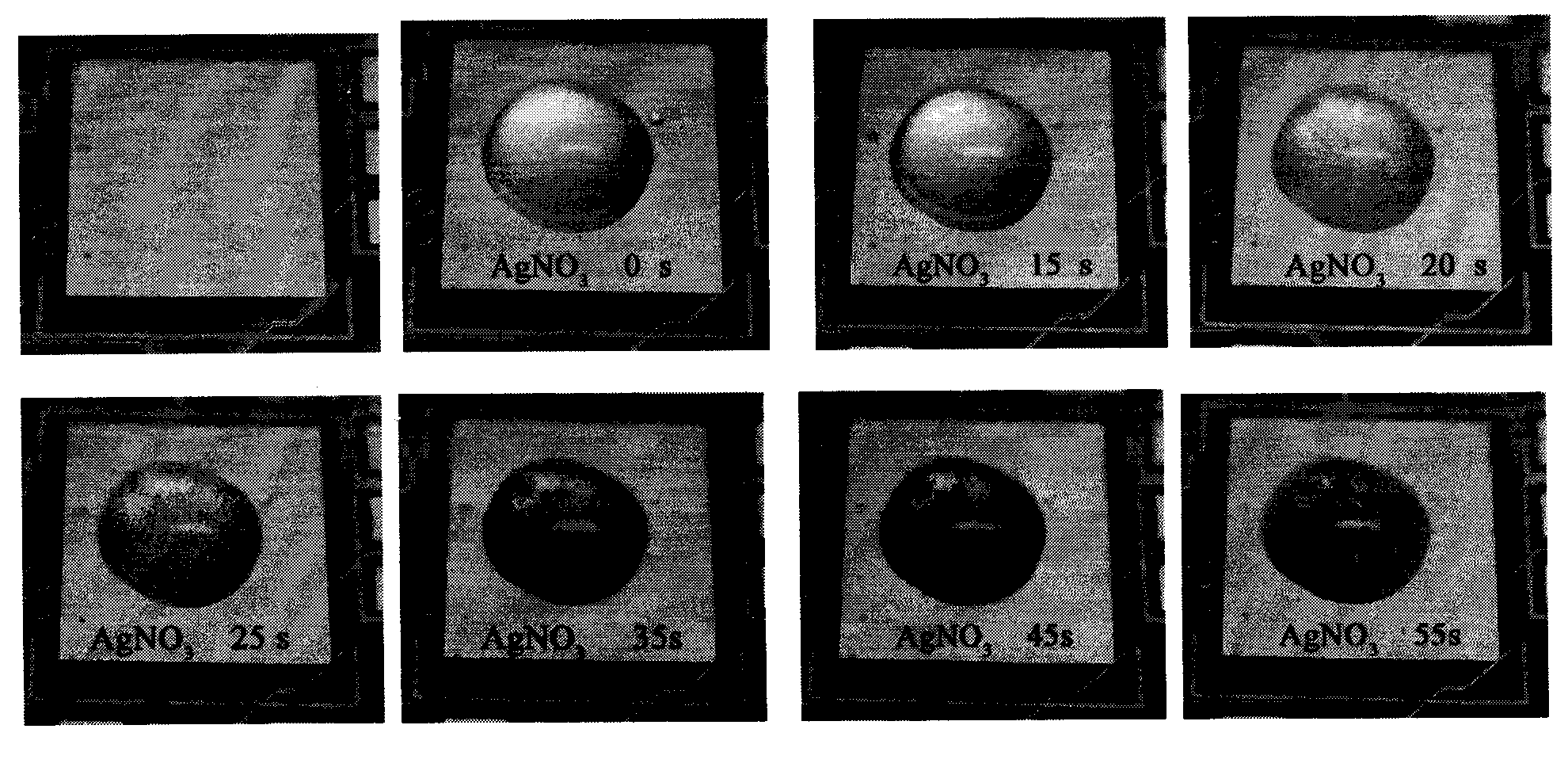

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

[0025] The compositions of Examples 1-6 and Comparative Examples 1-3 are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a pretreatment liquid of an organic weldable protective agent preparation method, which is suitable for antioxidant operation of finishing surface processing working procedurein the manufacture process of a printed-circuit board (PCB). The pretreatment liquid is prepared by no less than two benzimidazole derivatives, no less than two substituted carboxylic acid ammonium salts and deionized water, wherein the usage of the benzimidazole derivative is 0.005%-0.25% and the usage of substituted carboxylic acids ammonium salt is 0.05-0.5%. The pretreatment liquid can obviously improve the reaction activity of the copper surface, adjusts the deposition reaction of the follow-up OSP, improves the compactness and hydrophobicity of the final OSP coating; therefore, the pretreatment liquid can obviously increase the anti-oxidation capability of the printed circuit board in the storage process and the high temperature usage condition, meets the excellent weldable requirements of an electronic assembly plant on the printed circuit board.

Description

technical field [0001] The invention relates to the technical field of electronic chemicals, in particular to a pretreatment liquid used in an organic solderable preservative (OSP) process and a preparation method thereof. Background technique [0002] The organic solderable preservative process (OSP) has been used in the industry for many years. Its main function is to perform anti-corrosion and anti-oxidation treatment on the copper surface pads of PCB (Printed Circuit Board, that is, printed circuit boards), so that the copper surface pads can be used for a long time. It is not easy to oxidize during storage and under high temperature conditions, maintaining the excellent solderability of the pad. Foreign Japanese patents 5-186888, 7-24305, US patents 5376189, 5173130 and European patent EP0791671 have described the protection technology in detail. Their film-forming substances include benzotriazole, benzimidazole and arylphenylimidazole, etc. The advantages are water-so...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F11/14H05K3/28

Inventor 肖定军刘彬云王植材李卫明

Owner GUANGDONG TONESET SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com