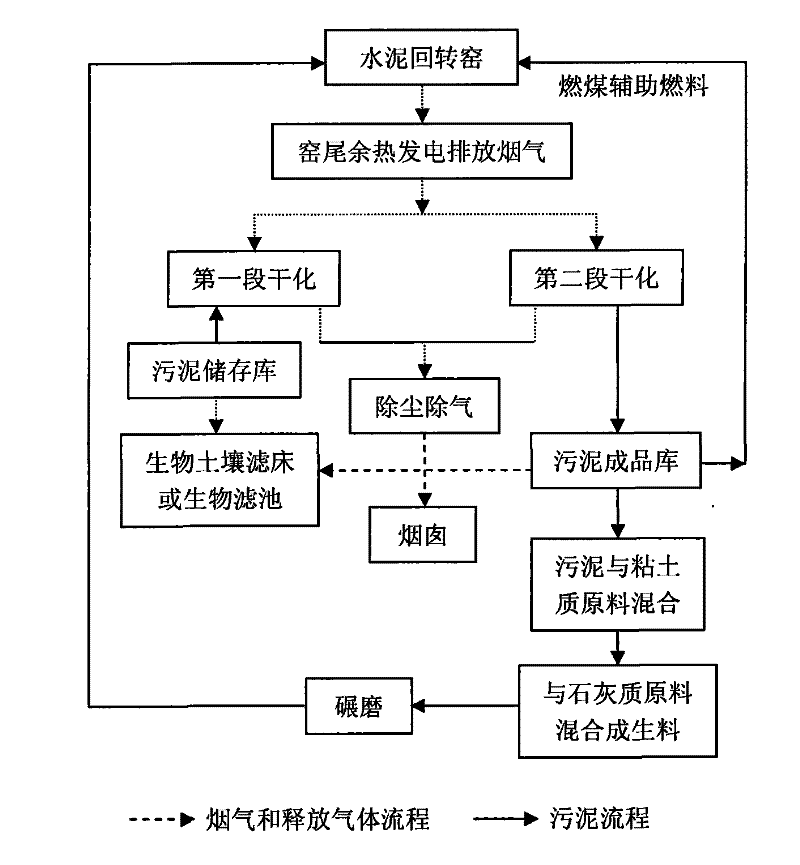

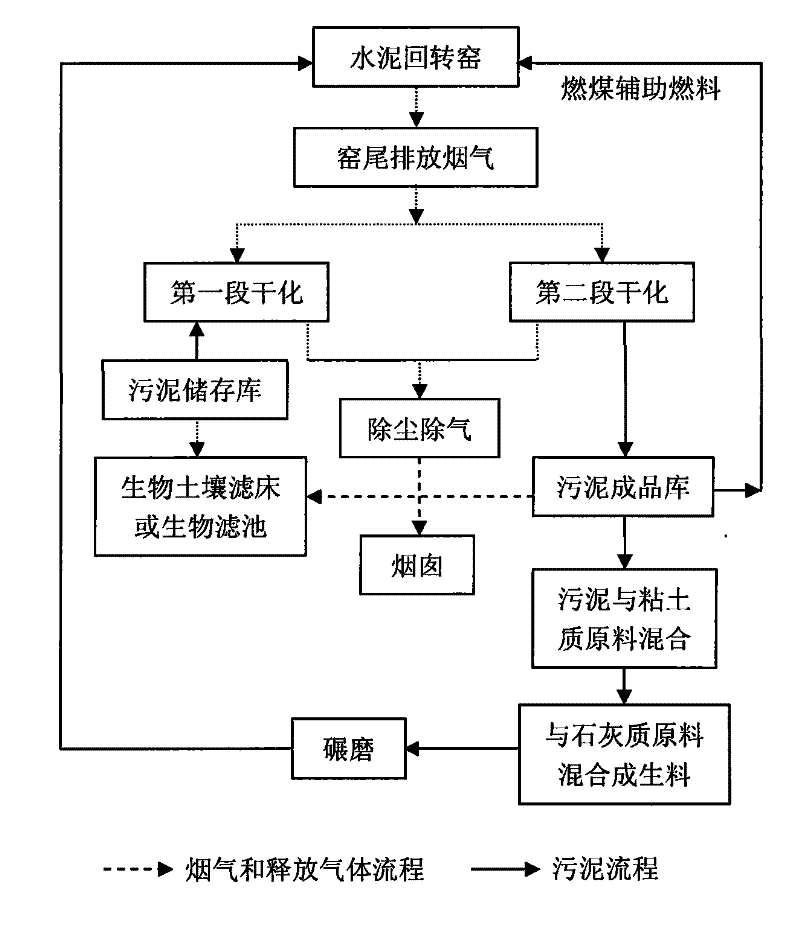

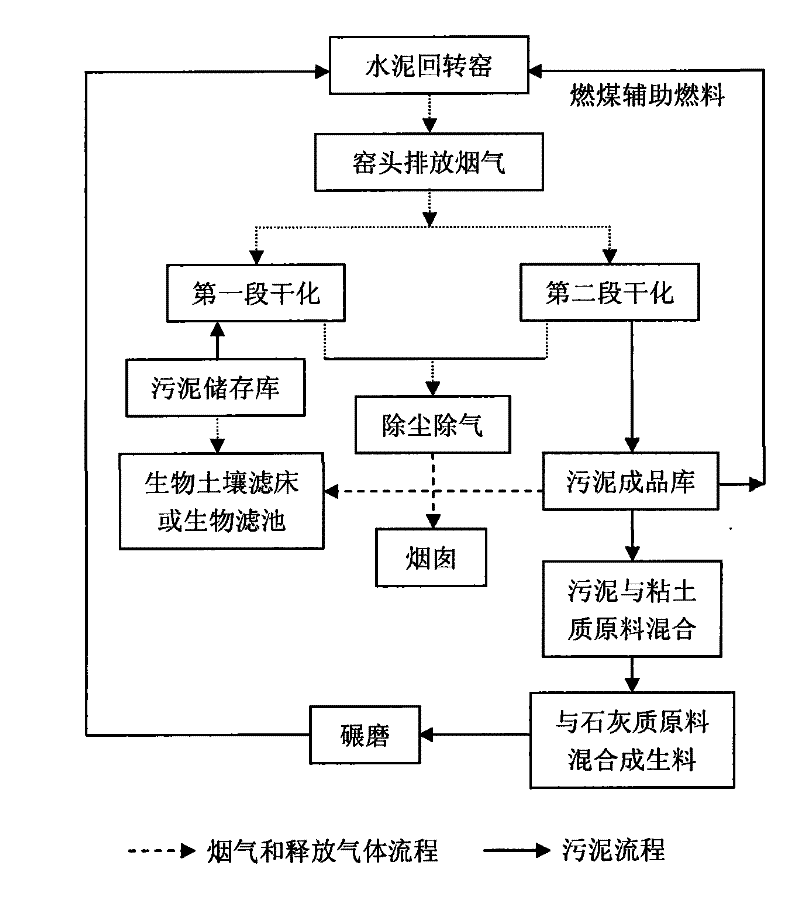

Method for utilizing fume afterheat of cement plant to heat-dry sludge and prepare cement by firing sludge

A technology of flue gas waste heat and sludge drying, which is applied in dewatering/drying/concentrating sludge treatment, cement production and other directions, can solve the problems of atmospheric environmental pollution, large occupation and harm, and achieve the effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A special sludge transport vehicle sends the sludge from the urban sewage treatment plant with a moisture content of 80% to the sludge storage, and stacks it for 4 days, and uses a mixer to homogenize the sludge on the one hand and evaporate the sludge naturally on the other hand A part of the water is released from the sludge storage, and sent to the biological filter through the induced draft fan, and discharged up to the standard.

[0076] The moisture content of the pretreated sludge is reduced to 78%. The sludge is sent to the first sludge drying and granulating device at a certain time interval through the component feeder for the first stage of sludge drying. A sludge drying and granulating device has a cylinder with a diameter of 2.2m and a length of 24m. The induced draft fan discharges the hot flue gas with a waste heat temperature of 200°C from the waste heat power generation boiler at the tail end of the cement rotary kiln. The air volume is controlled by the...

Embodiment 2

[0080] A special sludge transport vehicle sends the sludge from the urban sewage treatment plant with a water content of 78% to the sludge storage, and piles it up for 3 days, and uses a mixer to homogenize the sludge on the one hand and evaporate the sludge naturally on the other hand A part of the water is released from the sludge storage, and sent to the biological filter through the induced draft fan, and discharged up to the standard.

[0081] The moisture content of the pretreated sludge is reduced to 77%. The sludge is sent to the first sludge drying and granulating device at a certain time interval through the component feeder for the first stage of sludge drying. A sludge drying and granulating device has a cylinder with a diameter of 2.0m and a length of 22m. The induced draft fan sends the hot flue gas with a waste heat temperature of 350°C from the tail of the cement rotary kiln to the first The sludge drying and granulating device is in direct contact with the slu...

Embodiment 3

[0085] A special sludge transport vehicle sends the sludge from the urban sewage treatment plant with a moisture content of 76% to the sludge storage, and stacks it for 5 days, and uses a mixer to homogenize the sludge on the one hand and evaporate the sludge naturally on the other hand A part of the water is released from the sludge storage, and sent to the biological filter through the induced draft fan, and discharged up to the standard.

[0086] The moisture content of the pretreated sludge is reduced to 75%. Through the component feeder, the sludge is sent to the first sludge drying and granulating device at a certain time interval for the first stage of sludge drying. A sludge drying and granulating device has a cylinder with a diameter of 2.4m and a length of 26m. The induced draft fan sends the hot flue gas with a waste heat temperature of 120°C from the cement rotary kiln head to the first The sludge drying and granulating device is in direct contact with the sludge w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com