Poly-ferrocene graft polymer and preparation method thereof

A technology of polyferrocene grafting and polyferrocenesilane, which is applied in the field of polyferrocene graft polymer and its preparation, and achieves the effects of good processing performance and excellent comprehensive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

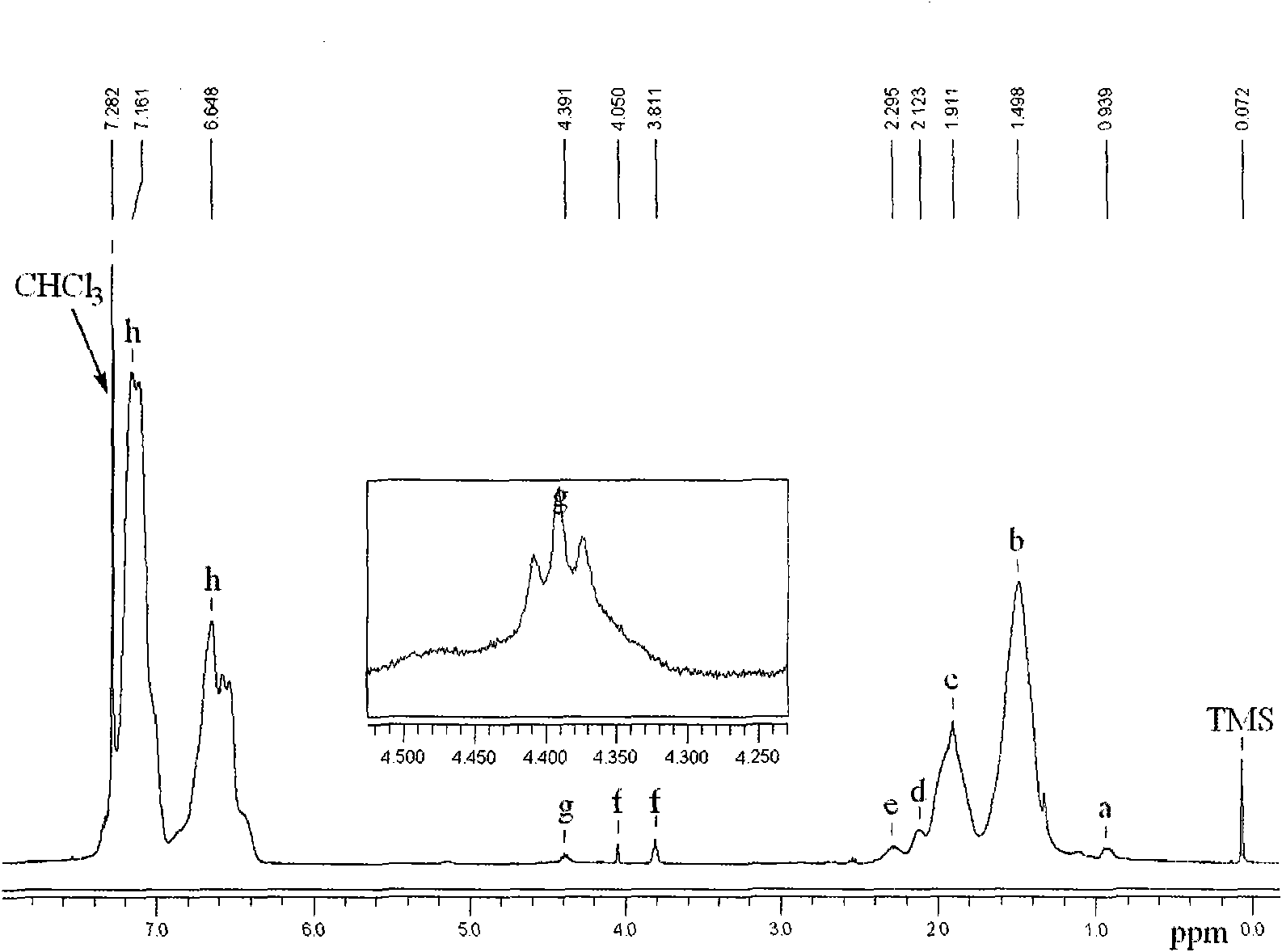

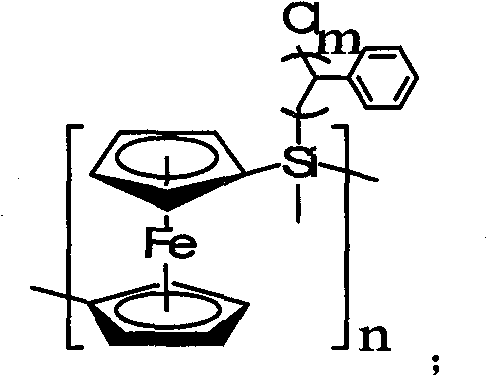

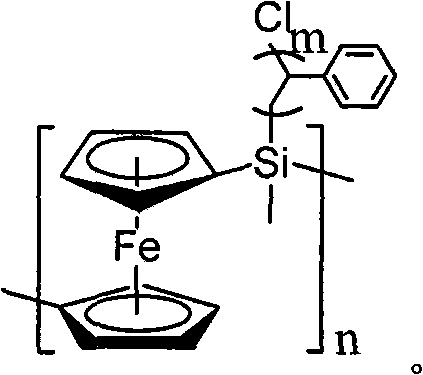

Image

Examples

Embodiment 1

[0020] Embodiment 1: The specific steps of the technical solution of this embodiment are as follows:

[0021] 1. Raw material refining

[0022] Weigh 120g of CuCl into a 500mL beaker, add 300mL of concentrated hydrochloric acid with a mass concentration of 36~38%, and magnetically stir to dissolve it to obtain a saturated hydrochloric acid solution; then use a 1000mL beaker to measure 600mL of deionized water and transfer the saturated hydrochloric acid solution slowly Dilute it, stir it magnetically, and remove the upper light green clear liquid after centrifugation to obtain a white solid powder; repeat the above operation twice. Finally, it was washed with 3×100 mL of absolute ethanol, and the solid was transferred to a 250 mL Schlenk bottle. In an anhydrous and oxygen-free environment, magnetically stirred for 15 minutes, and allowed to stand for 20 minutes to remove the supernatant. Then wash with 2×100mL ether; dry N at room temperature 2 In the atmosphere, dry for use.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com