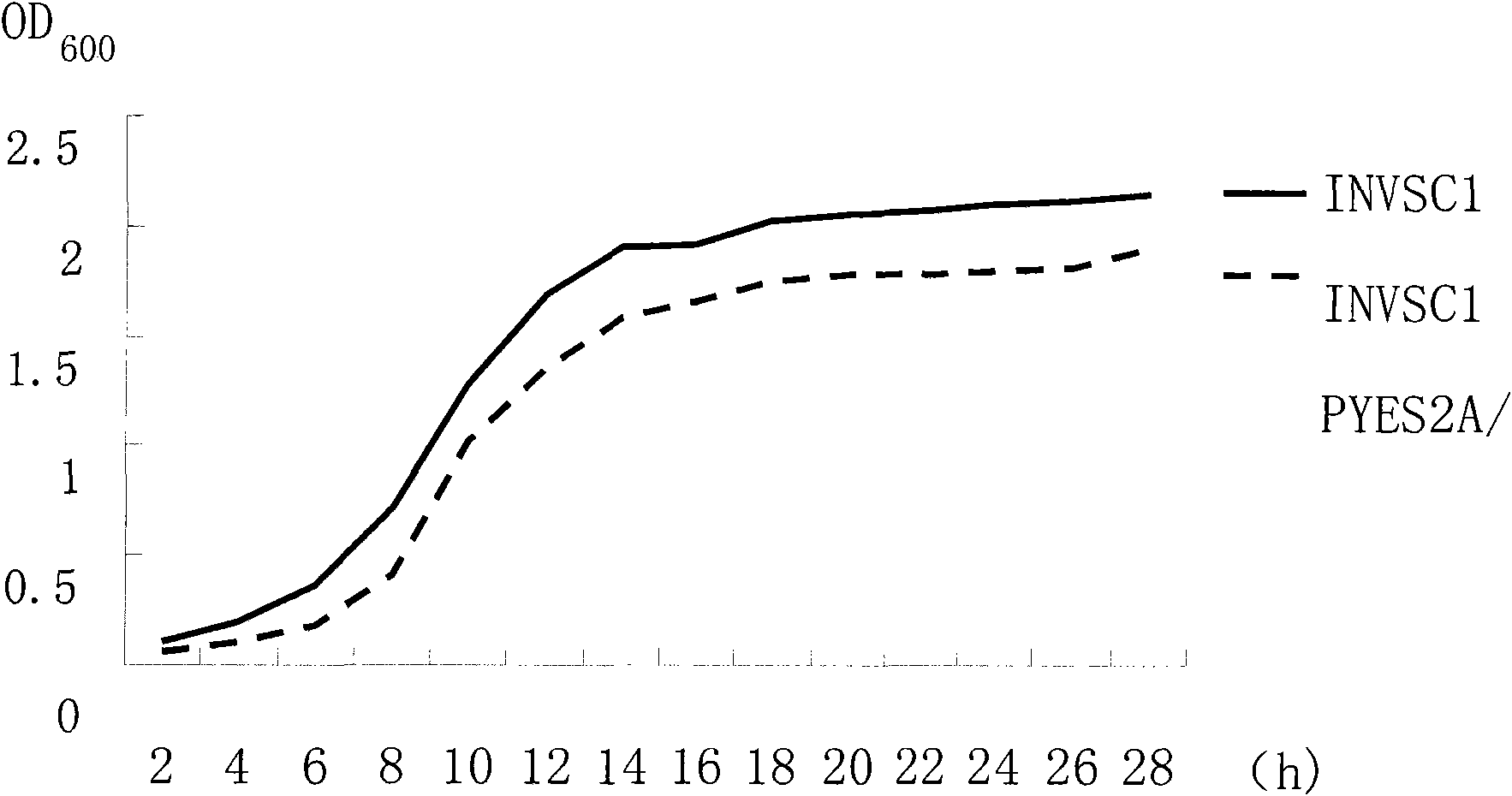

Method for expressing androctonus australis hector toxin by saccharomyces cerevisiae

A yeast expression and North African scorpion technology, applied in the biological field, can solve problems such as blocked exports, increased residual toxicity, and straight-up increase in pest resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

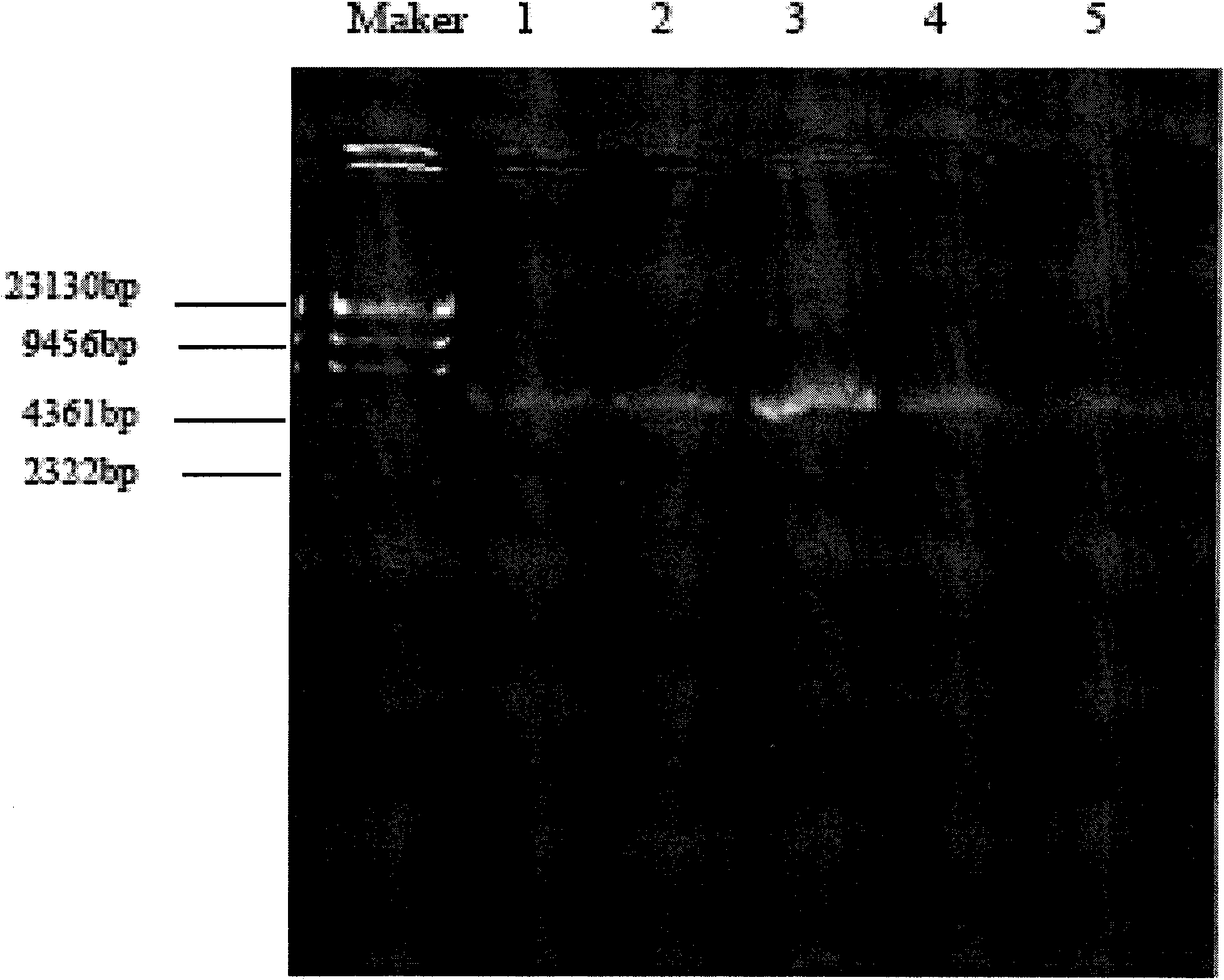

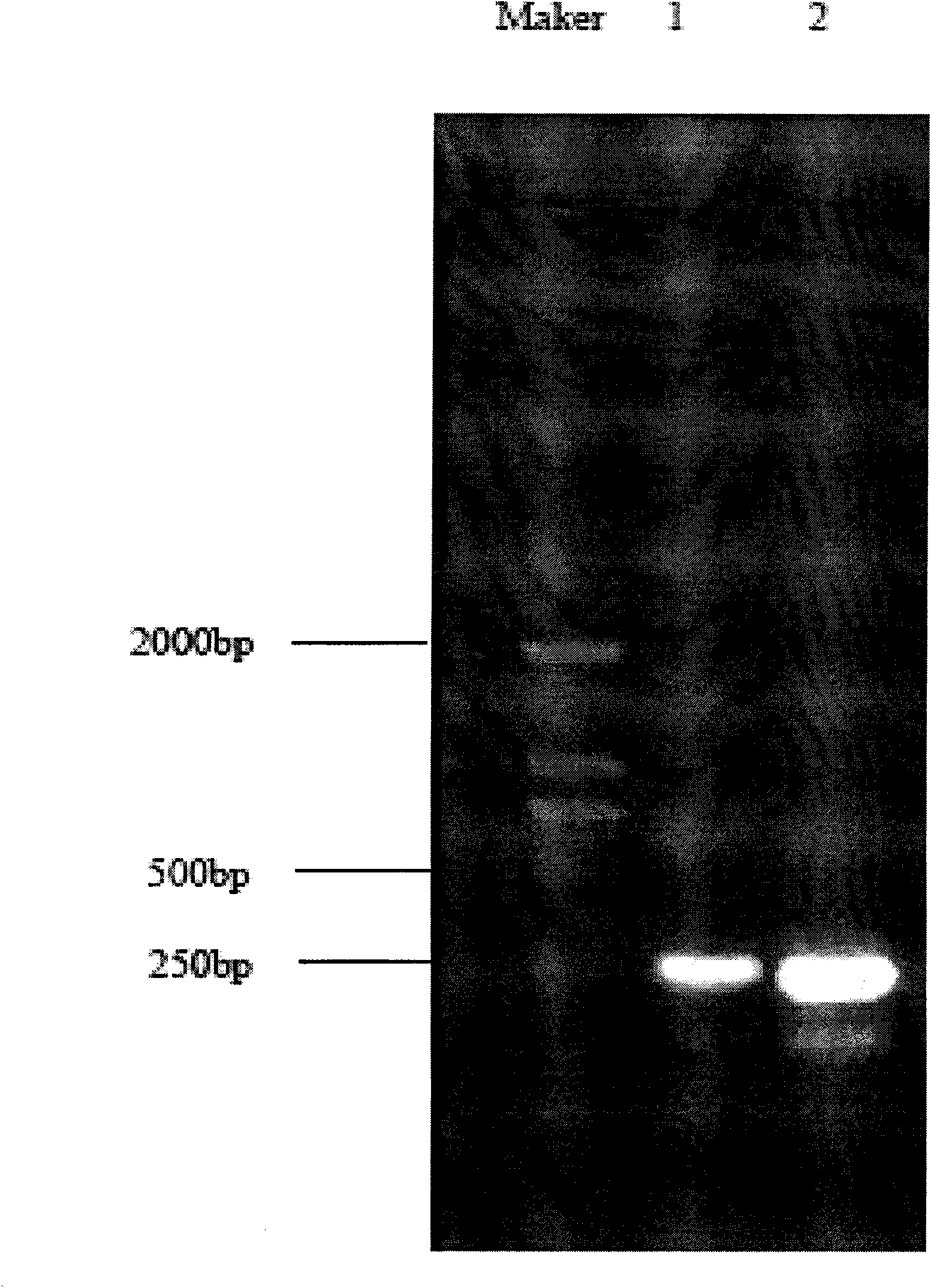

[0054] AaHIT1 was amplified by PCR using the plasmid pMD18-T / AaHIT1 with the AaHIT1 gene as a template and P1 (SEQ No. 1: 5'GCGAAGCTTATGAAGAAGAACGGCTACGCGGTGGACAGC 3') and P2 (SEQ No. 2: 5'GGCGGATCCTTAGTTGATGATGGTGGTGTCGCAGT 3') as primers Gene, PCR reaction cycle: 94°C for 2 minutes, 35 cycles at 94°C for 30 seconds-62°C for 30 seconds-72°C for 30 seconds, and 72°C for 5 minutes.

[0055] The PCR products were detected by electrophoresis and recovered for use.

[0056] Electrophoresis recovery of PCR products, the main steps are:

[0057] 1) PCR products were separated by electrophoresis using Agarose gel. Separate the target DNA fragment from other DNA as much as possible, then use a clean scalpel to cut off the agar block containing the DNA to be recovered, and put it into a 1.5mL centrifuge tube.

[0058] 2) Add 400 μL of Solution SN per 100 mg of Agarose gel, place in a water bath at 55-65°C for 5 minutes, and mix several times in the middle until the gel is completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com