Methods of removing F and Cl in secondary zinc oxide dust effectively and producing electrolytic zinc

A sub-zinc oxide and soot technology, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of difficulty in stripping zinc cathode, anode corrosion, poor removal effect of sub-zinc oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

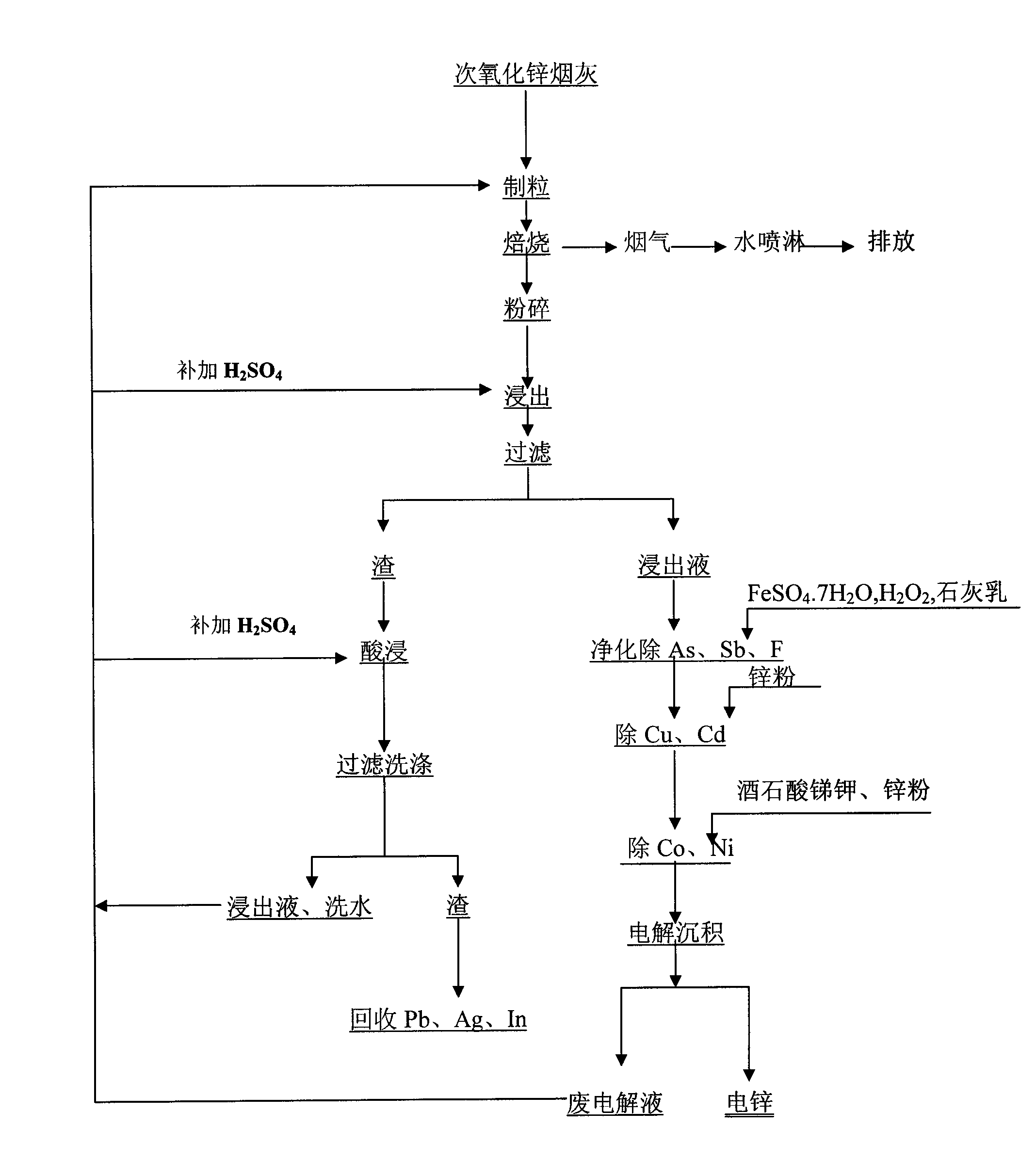

Method used

Image

Examples

Embodiment

[0037] For secondary zinc oxide raw materials (Zn44.27%, Pb17.45, Cu0.12%, Cd0.21%, As1.18, Sb0.39%, Ni0.001%, Co0. 001%, F0.3%, Cl0.25%) carried out acidification and granulation rotary kiln roasting to strengthen the de-F, Cl, purification, electrolytic production of zinc research, the specific implementation steps are as follows:

[0038] 1) Acidification granulation: adding 15% Zn-containing soot to sub-zinc oxide soot 2+ : 45~50g / l, H 2 SO 4 : 140~160g / l waste electrolyte, granulated by a disc granulator, and the particle size is controlled to be 8~15mm;

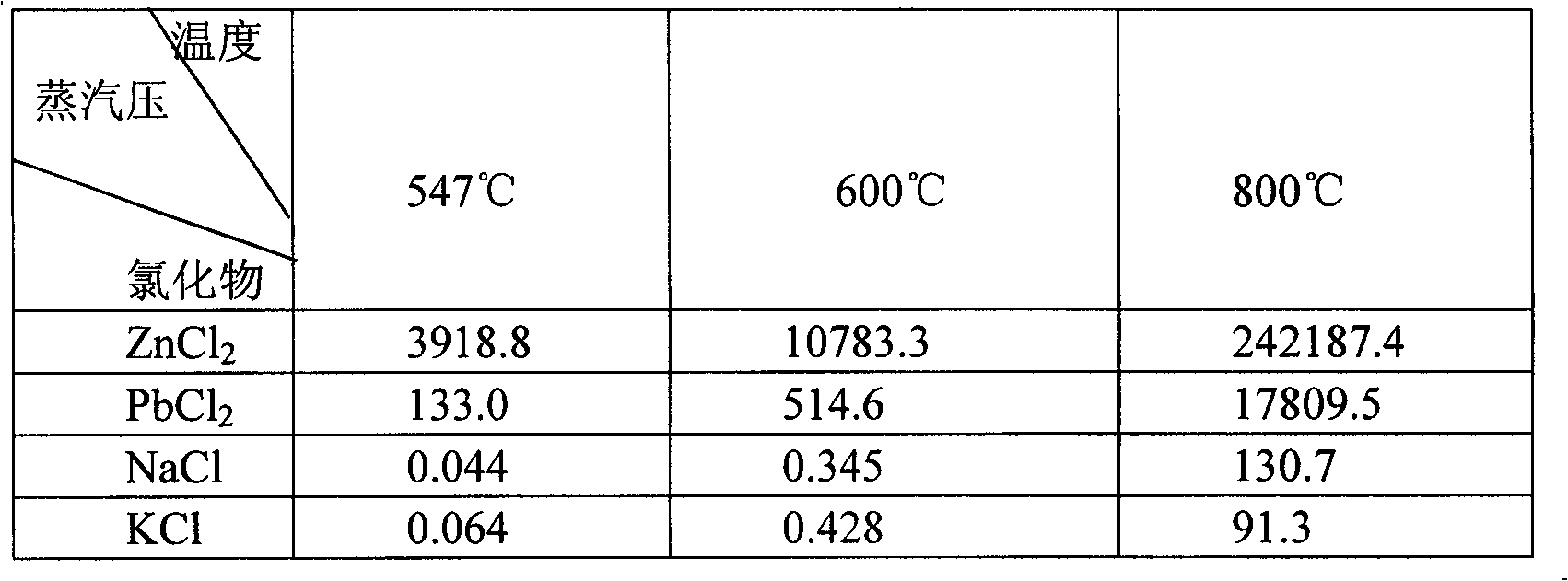

[0039] 2) Rotary kiln roasting of pellets: temperature 650-800°C, time 1.5-2.5h, feeding speed 90g / min, kiln speed 1.2r / min.

[0040] 3) Leaching: control conditions: temperature 85-90°C, L / S=4-4.5:1, first pH control 3-3.5, leaching time 4.0h, pulp filtration to obtain leaching slag and leachate.

[0041] 4) Detection of As, Sb, and F contents in the leachate. The leaching solution is first added with FeSO which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com