Nano iron oxide /graphite composite electromagnetic absorption material and preparation method thereof

A nano-iron oxide and absorbing material technology, applied in the parts, shielding, instruments and other directions of the instrument, can solve the problems of small operating temperature range, low frequency absorption performance, absorption frequency bandwidth, etc., and achieve the expansion of low frequency absorption. Frequency range, effect of suppressing crystal growth and agglomeration, improving high temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

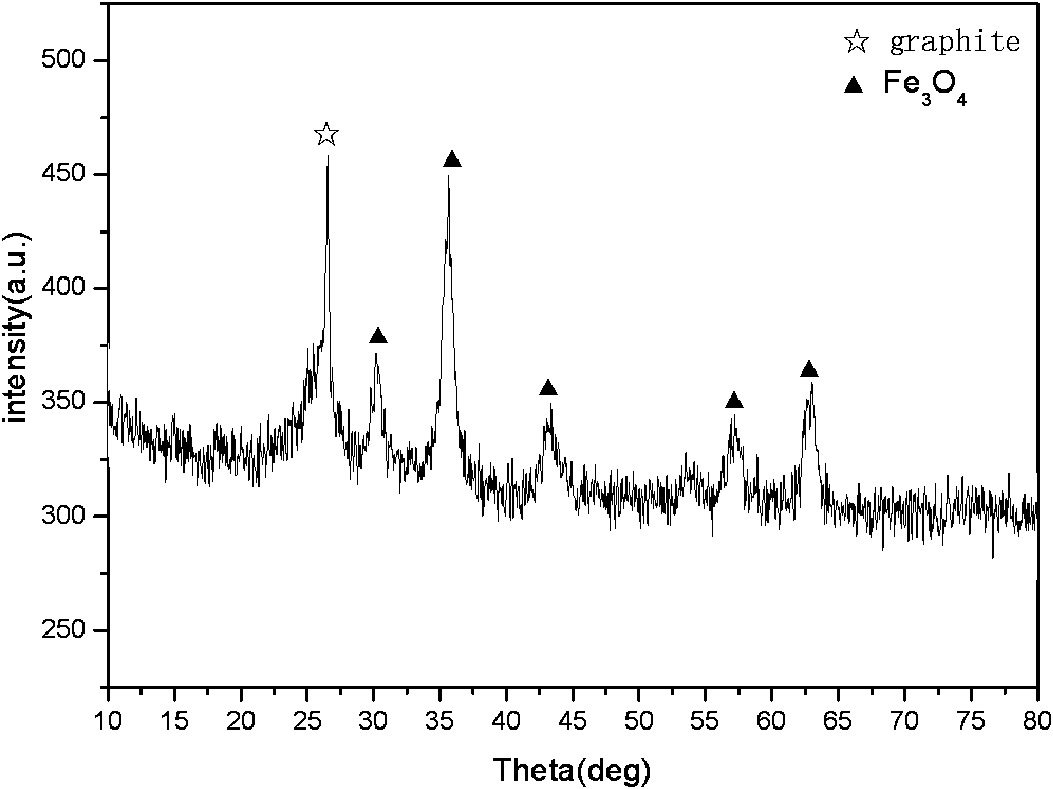

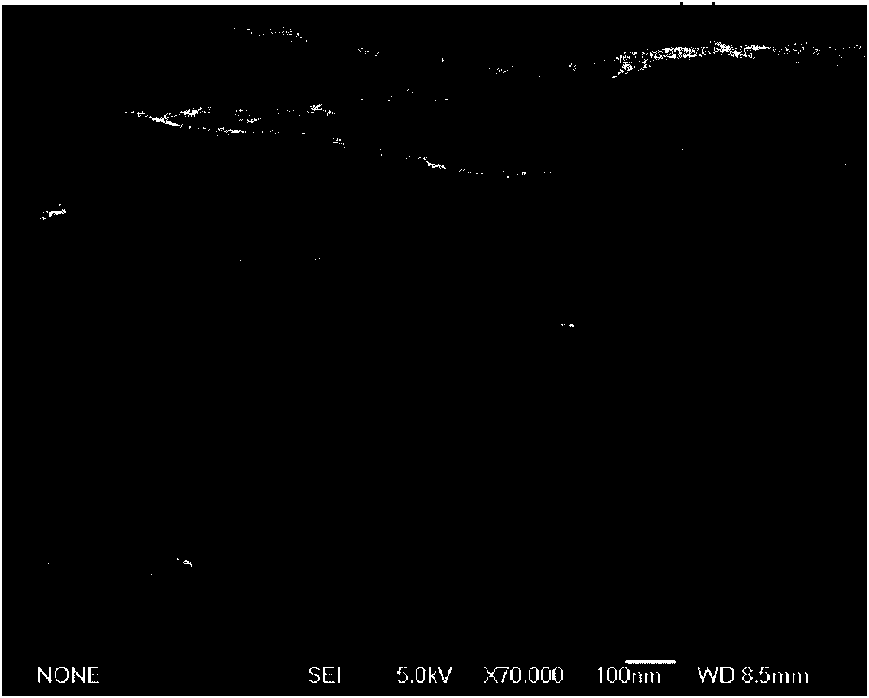

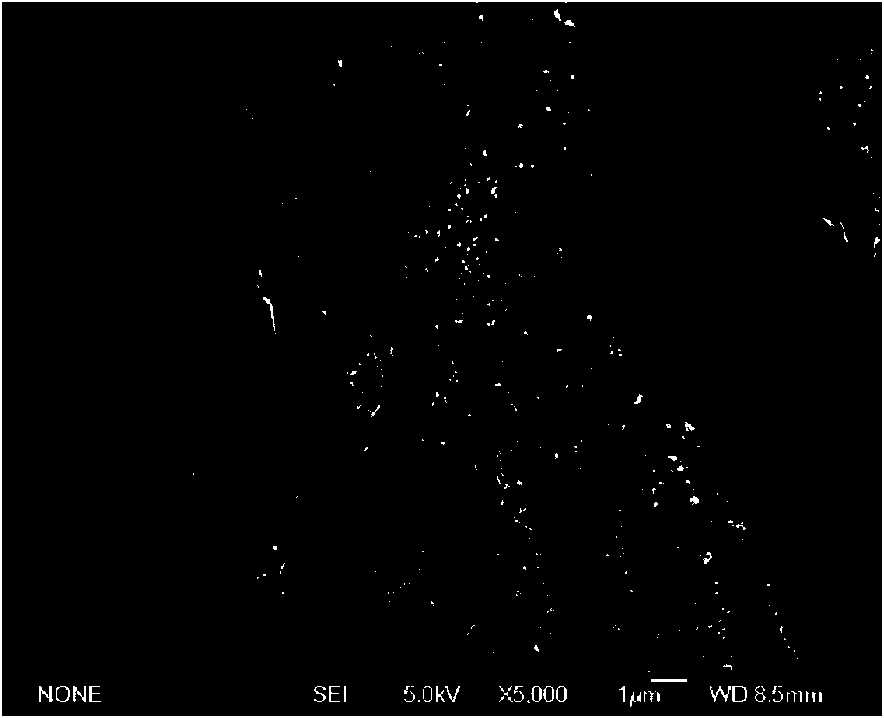

[0022] Add 100g of ferric citrate into a beaker, dissolve it completely in 1000ml of water, adjust the pH value to between 6 and 8, add it to the prepared 0.1g / ml graphite oxide aqueous solution, stir for 30min, and put it in a drying oven at 80°C After drying for 48 hours, the obtained solid was ground to 200 mesh, and then put into a muffle furnace for heat treatment to obtain a nano-iron oxide / graphite composite material. The mass ratio of iron salt to graphite oxide is: 1:1-3:1. The heat treatment temperature is 800°C, and the heat treatment is 3 to 14 hours. The main component of iron oxide is Fe 3 o 4 , Fe 2 o 3 , Fe.

example 2

[0024] Add 50g of ferric nitrate into a beaker, dissolve it completely in 100ml of water, add it into the prepared 0.1g / ml graphite oxide aqueous solution, stir for 30min, put it in a drying oven at 80°C for 48h, and grind the obtained solid to 200 mesh , and then heat-treated in a muffle furnace to obtain a nano-iron oxide / graphite composite material. The mass ratio of iron salt to graphite oxide is 3:1. The heat treatment temperature is 500°C, and the heat treatment is 14h. The main component of iron oxide is Fe 3 o 4 , Fe 2 o 3 .

example 3

[0026] Add 100g of ferric chloride into the beaker, dissolve it completely in 1000ml of water, adjust the pH value to between 6 and 8 with hydrochloric acid, add it to the prepared 0.1g / ml graphite oxide aqueous solution, stir for 30min, and put it in 80℃ Dry it in a drying oven for 48 hours, grind the obtained solid to 200 mesh, and put it into a muffle furnace for heat treatment to obtain a nano-iron oxide / graphite composite material. The mass ratio of iron salt to graphite oxide is: 1:1-3:1. The heat treatment temperature is 700°C, and the heat treatment is 3 to 14 hours. The main component of iron oxide is Fe 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com