Method for preparing quartz crystal devices by laser soldering seal

A quartz crystal and laser technology, applied in the field of electricity, can solve the problems of poor quality of welded metal cover, difficulty in welding of small-sized ceramic package base, low efficiency, etc., and achieve the effect of fast welding speed, small deformation and large depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

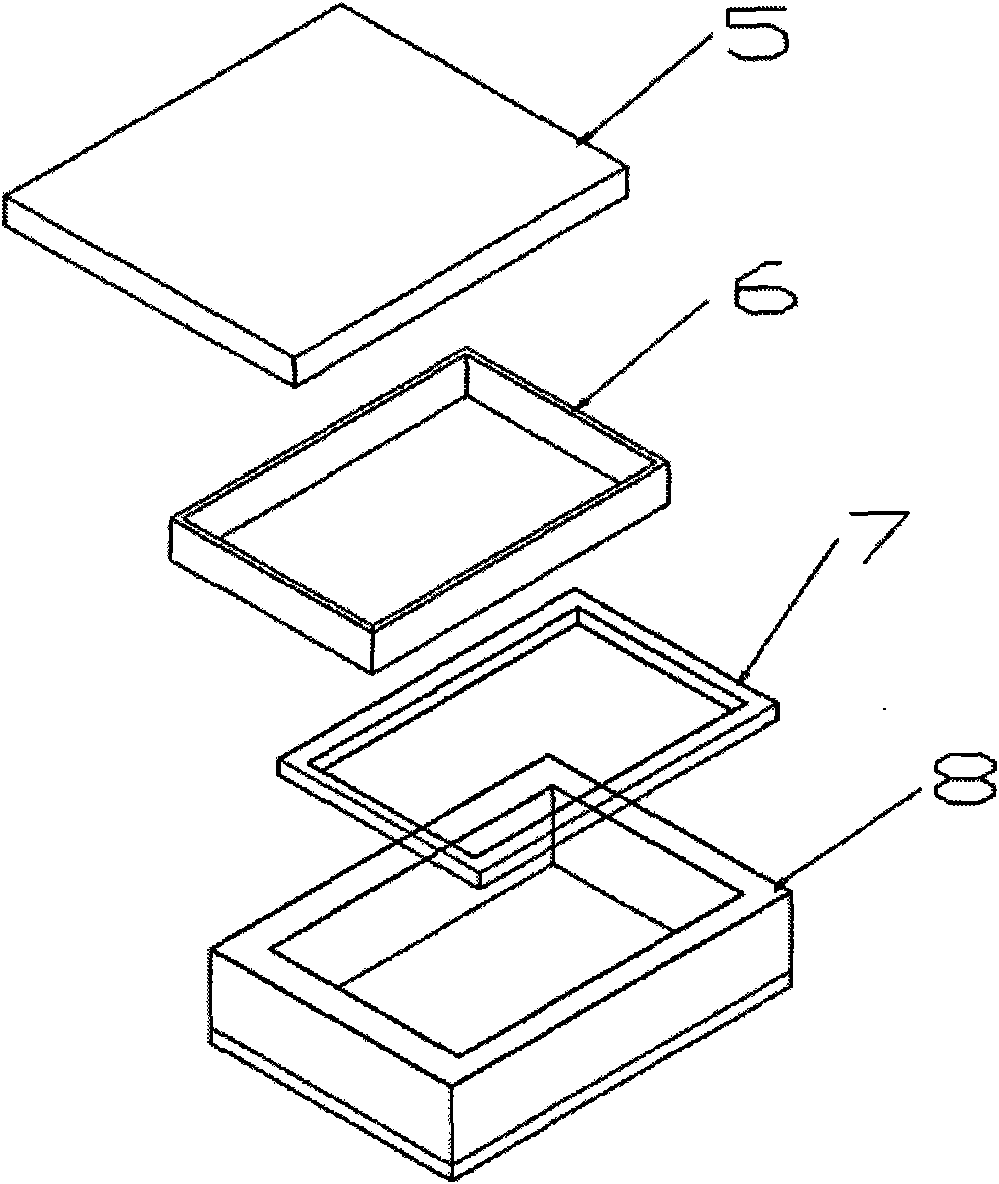

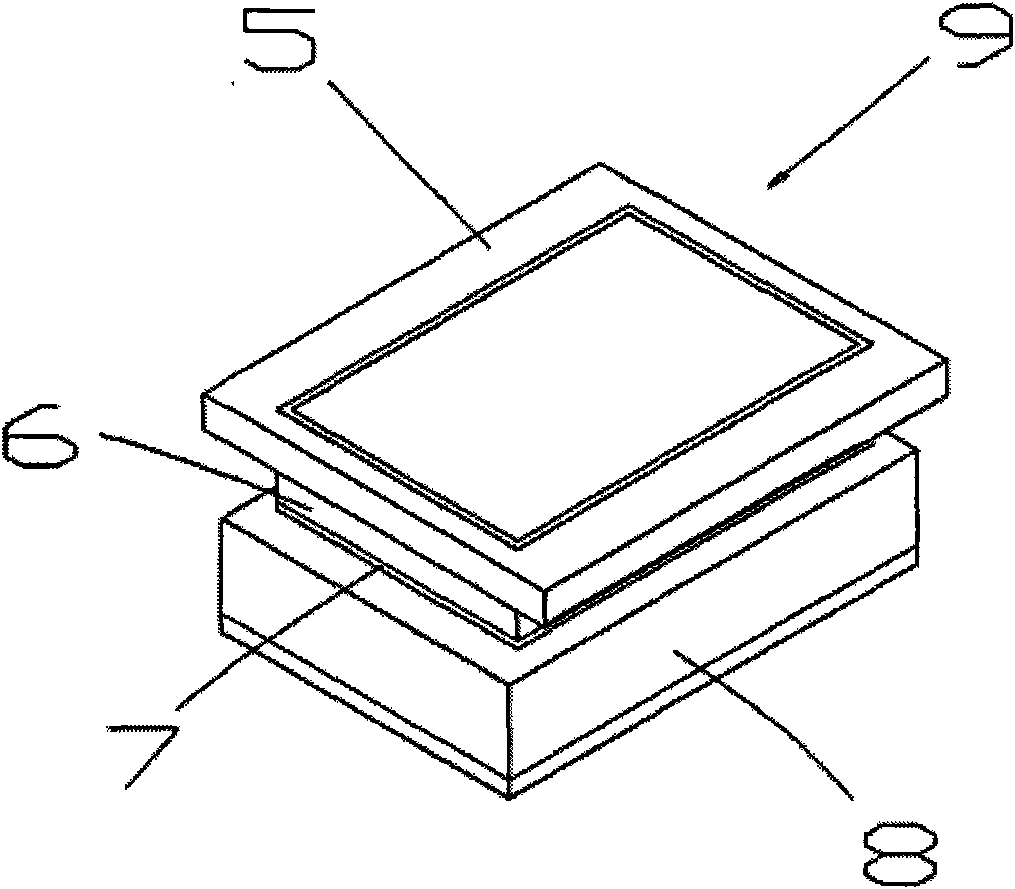

[0018] combine figure 1 and figure 2 As shown, the tungsten metal layer is printed with nickel or gold plating around the opening of the upper end of the ceramic package base 8, and then the silver copper solder 7 is placed and the punched Kovar ring 6 is welded in a reducing atmosphere at 850±20°C, and then the Kovar ring 6 is welded on the Kovar alloy Cover the metal cover 5 above the ring 6; Figure 5 As shown, the semi-finished product 3 after the above steps is placed in an airtight transparent space 4 filled with inert gas such as nitrogen or argon, and the laser source 20 is a CO2 laser or a YAG laser. 5 and Kovar alloy ring 6 are laser welded, so that the quartz crystal is packaged in a four-layer structure composed of ceramic package base 8, silver-copper solder 7, Kovar alloy ring 6 and metal cover 5, forming a quartz crystal device 9 (such as figure 2 shown).

Embodiment 2

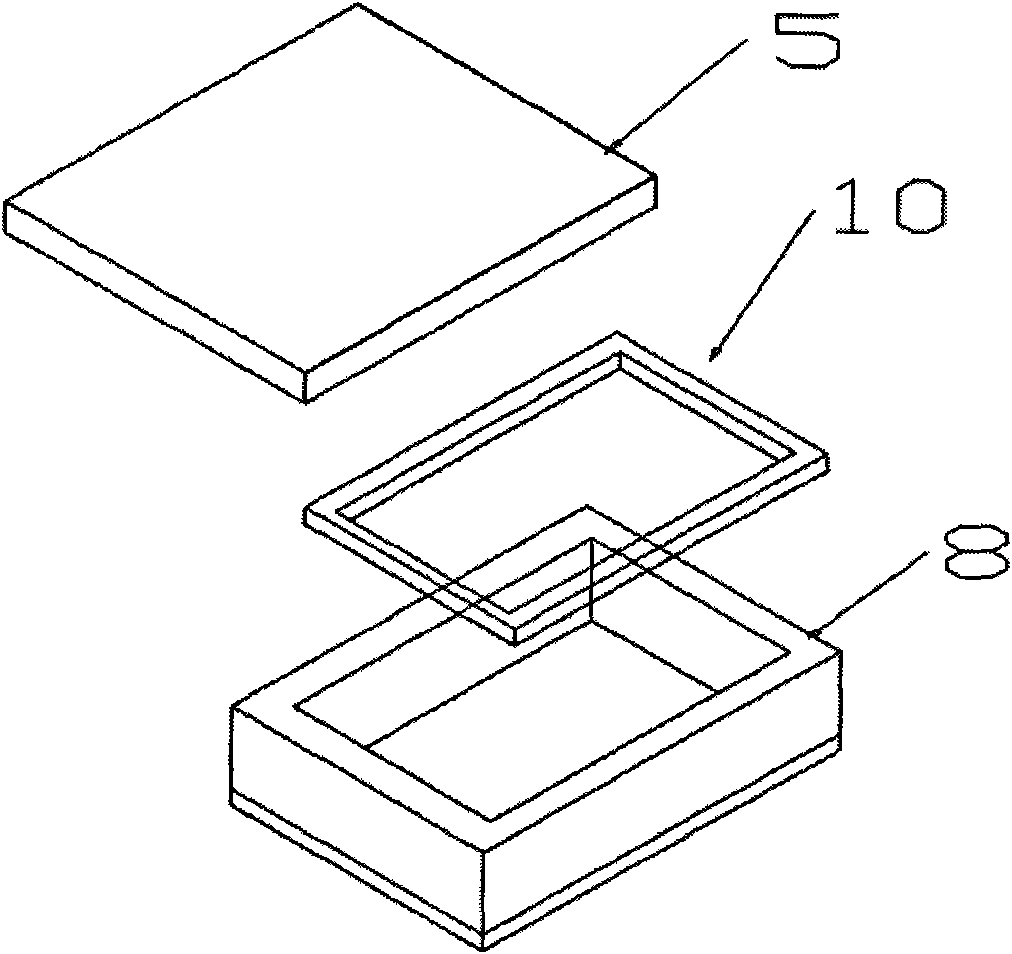

[0020] combine image 3 and Figure 4 As shown, a quartz crystal is placed in the ceramic package base 8, specifically, the quartz crystal is mounted on the internal terminal (not shown) of the ceramic package base 8 that is conducted with the external terminal; surrounding the upper end of the ceramic package base 8 The opening is printed to form a Kovar ring 10, and sintered in a reducing atmosphere such as hydrogen at 850±20°C to obtain a ceramic package base with a Kovar ring 10, and then a metal cover 5 is placed on the top of the Kovar ring 10; Figure 5 As shown, the semi-finished product 3 after the above steps is placed in an airtight transparent space 4 filled with inert gases such as nitrogen or argon, and the laser source 20 is CO 2 Laser or YAG laser, after the laser beam 1 is focused by the prism 2, the metal cover 5 and the Kovar alloy ring 10 are laser welded, so that the quartz crystal is packaged on the ceramic packaging base 8, the Kovar alloy ring 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com