Lacidipine sustained-release preparation and preparation process thereof

A technology of lacidipine and preparations, which is applied in the field of salt sustained-release pharmaceutical preparations and its preparation, and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

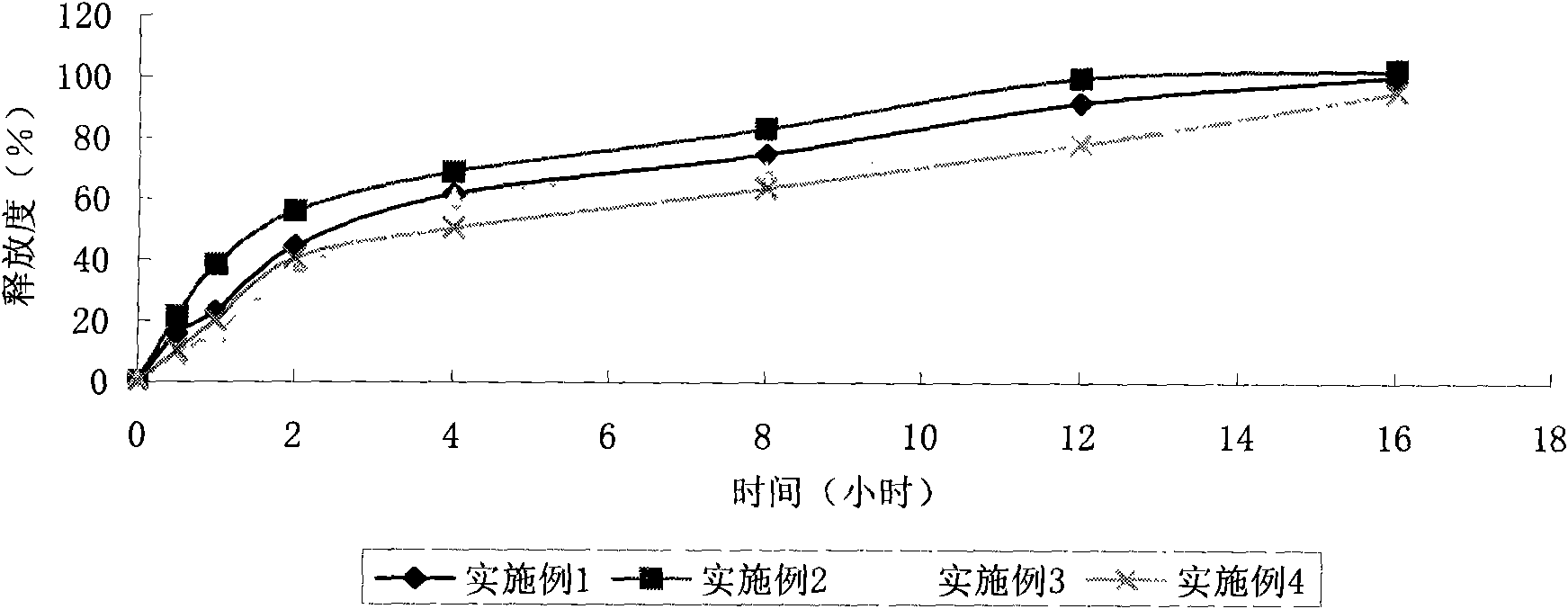

Examples

Embodiment 1

[0038] Plain Tablet Prescription:

[0039] Lacidipine 4g

[0040] Copovidone 20g

[0041] Microcrystalline Cellulose 40g

[0042] Lactose 84g

[0043] Hydroxypropyl Methyl Cellulose 60g

[0045] Proper amount of ethanol

[0046] Coating Solution Prescription:

[0047] Opadry 30g

[0048] Appropriate amount of water

[0049]Makes 1000 pieces

[0050] Preparation process

[0051] 1 Preparation process of plain tablets

[0052] 1.1 Preparation of dispersion Take the lacidipine and copovidone of the prescription amount and dissolve them in ethanol to make a 5% (w / w) copovidone ethanol dispersion for subsequent use;

[0053] 1.2 Granulation After sieving the lactose with 80 meshes, put it into the mixing granulator together with hypromellose and microcrystalline cellulose, mix, and add copovidone ethanol dispersion for wet granulation after uniformity, and take out the granules for 20 mesh sieve for wet sizing. After drying, pass through ...

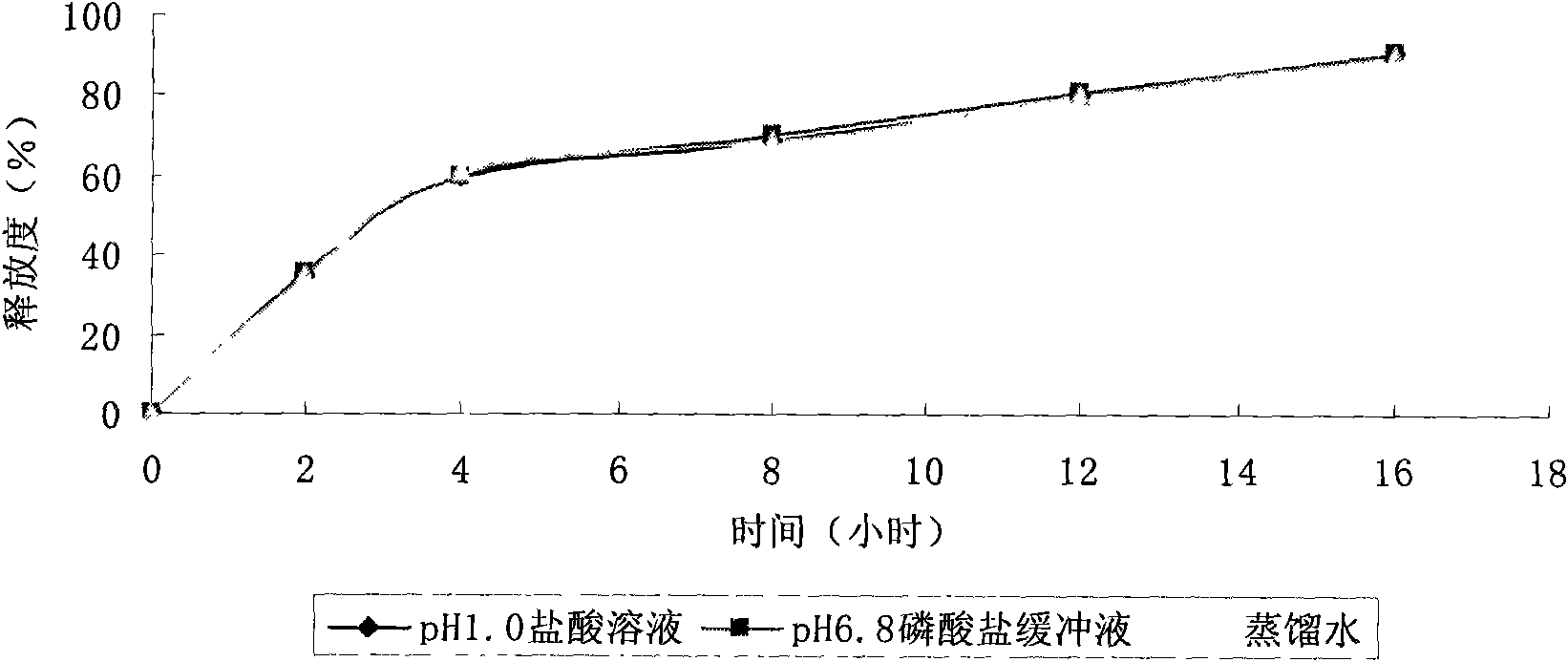

Embodiment 2

[0061] Plain Tablet Prescription:

[0062] Lacidipine 4g

[0063] Ethyl cellulose 60g

[0064] Microcrystalline Cellulose 30g

[0065] Mannitol 100g

[0066] Povidone 40g

[0067] Stearic acid 4g

[0068] Proper amount of ethanol

[0069] Coating Solution Prescription:

[0070] Opadry 30g

[0071] Appropriate amount of water

[0072] Makes 1000 pieces

[0073] Preparation process

[0074] 1 Preparation process of plain tablets

[0075] 1.1 Preparation of adhesive: Dissolve the povidone of the prescribed amount in ethanol to make a 10% (w / w) adhesive for subsequent use;

[0076] 1.2 Granulation Put lacidipine and mannitol through 80-mesh sieve respectively, put them into a mixing granulator together with hypromellose and microcrystalline cellulose, mix them, and then add binders to carry out wet granulation. Take out the granules and carry out wet sizing with a 20 mesh sieve. After drying, pass through a 20-mesh sieve for granulation and set aside.

[0077] 1.3 Ta...

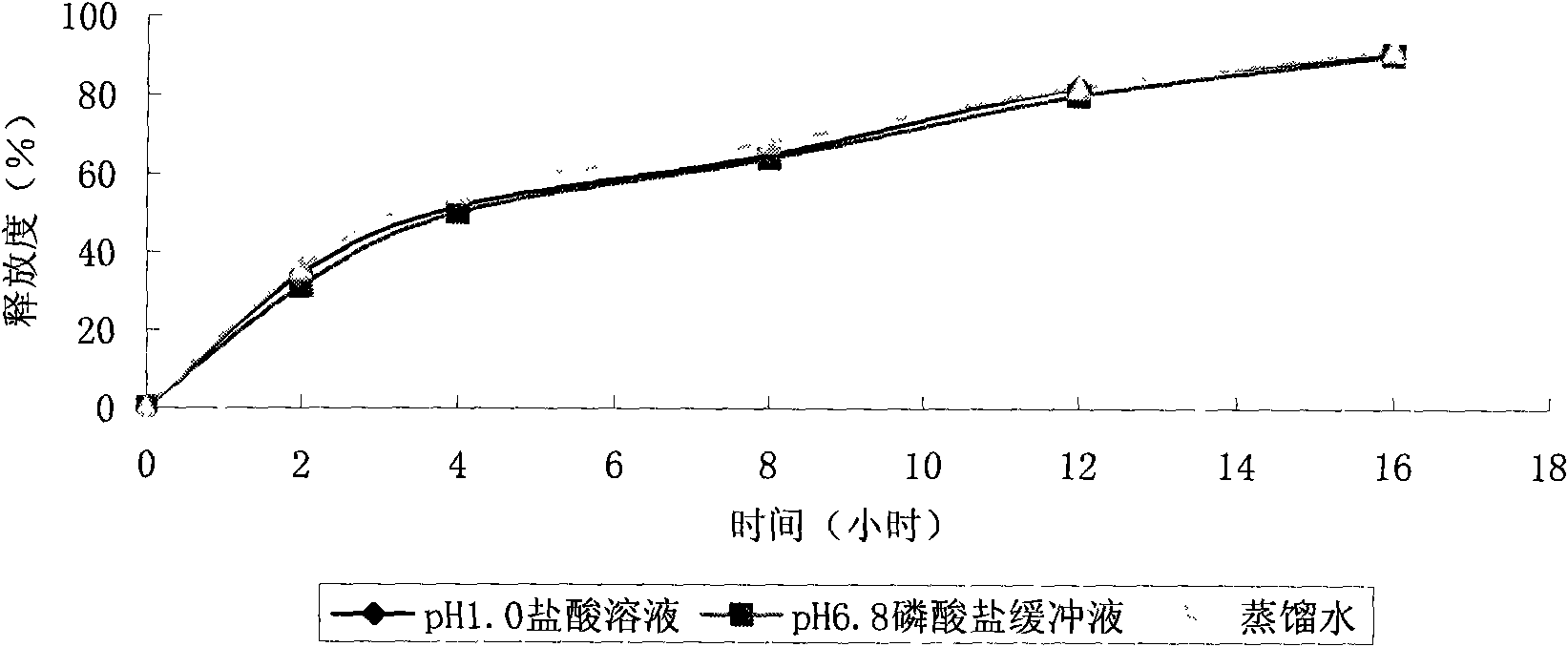

Embodiment 3

[0082] Plain Tablet Prescription:

[0083] Lacidipine 4g

[0084] Carnauba Wax 50g

[0085] Microcrystalline Cellulose 30g

[0086] Lactose 70g

[0087] Povidone 30g

[0089] Proper amount of ethanol

[0090] Makes 1000 pieces

[0091] Coating solution prescription: (1000 tablets dosage)

[0092] Cellulose diacetate 40g

[0093] Polyethylene glycol 5g

[0094] Dibutyl sebacate 4g

[0095] Proper amount of acetone

[0096] Preparation process

[0097] 1 Preparation process of plain tablets

[0098] 1.1 Preparation of adhesive: Dissolve the povidone of the prescribed amount in ethanol to make a 5% (w / w) adhesive for subsequent use;

[0099] 1.2 Granulation After sieving lactose and microcrystalline cellulose with 80 meshes respectively, put them into a mixing granulator together with lacidipine and carnauba wax, mix them, and add binders after they are uniform for wet granulation, and take out the granules for 20 mesh sieve for wet si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com