Preparation method of titanium dioxide nano powder

A nano-powder, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of unsuitability for industrial production, danger, and high equipment requirements, achieve uniform microscopic morphology and size, simple and easy-to-control steps, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

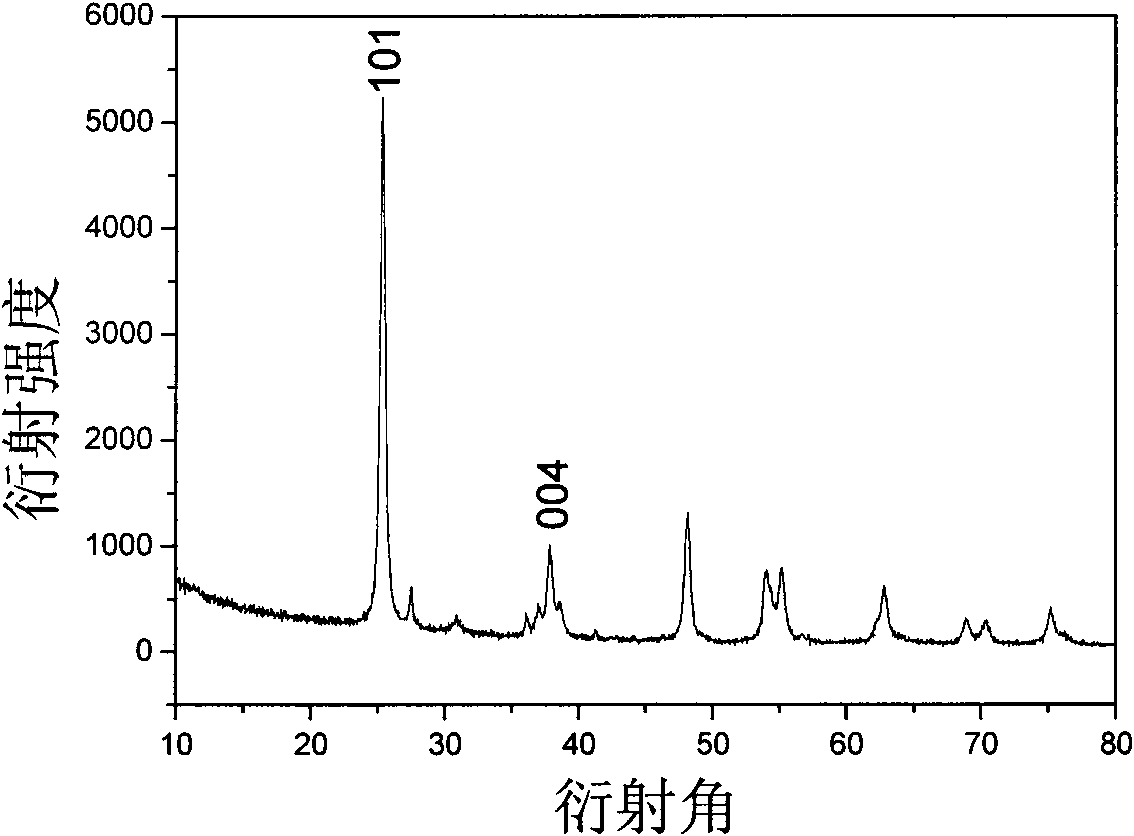

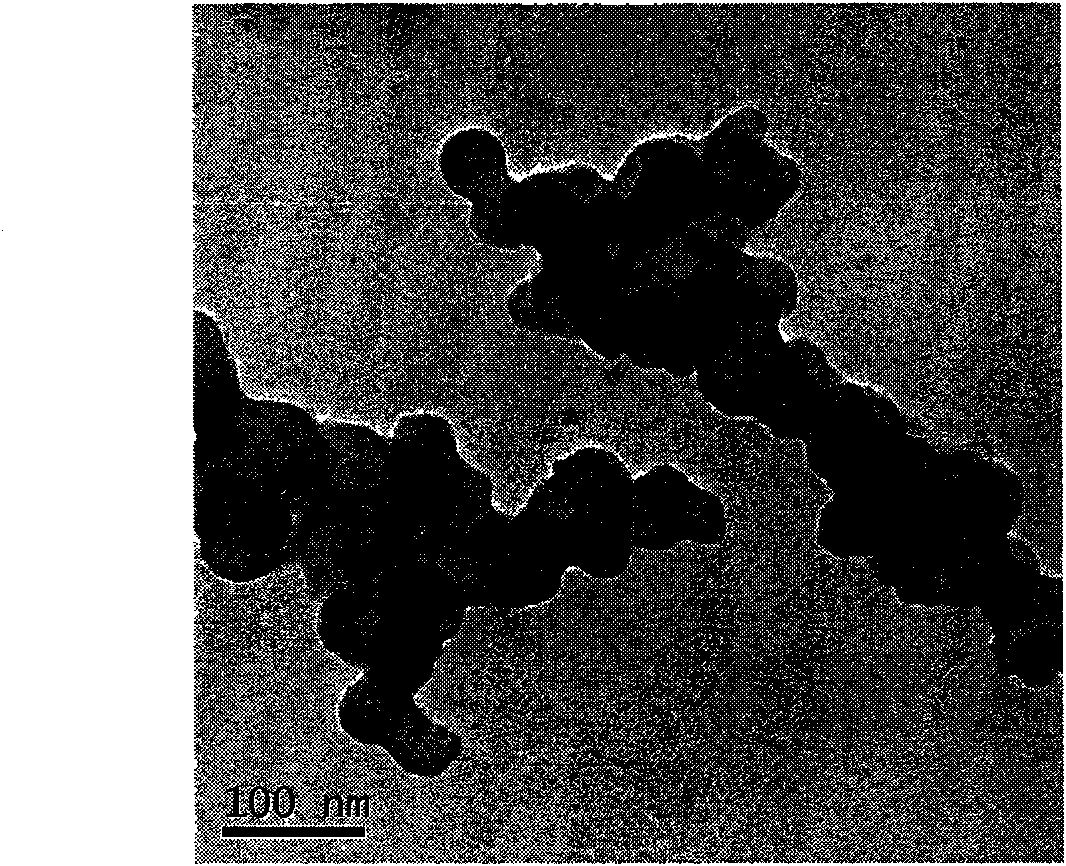

[0024] Weigh 10 g of solid paraffin and heat to 65°C until the paraffin is completely melted. Measure 20 g of butyl titanate, mix it with molten paraffin evenly under stirring, and cool while stirring to obtain a paraffin block dispersed with butyl titanate. Put the paraffin block dispersed with butyl titanate into water, heat and stir at 65°C until the paraffin wax is completely melted, and the butyl titanate is slowly released during the melting process, and hydrolyzes with water to form a uniformly dispersed emulsion . Then stand still and cool to room temperature, the emulsion appears to be separated, and the paraffin coagulates into blocks on the water surface, and the resulting flocculated solid slowly sinks to the bottom of the beaker, forming a precipitate. When no flocculated matter sinks, take out the wax block, centrifuge the remaining solution, dry the obtained solid naturally, and calcinate it in a muffle furnace at a temperature of 500°C to obtain anatase nano-t...

Embodiment 2

[0028] Weigh 10 g of solid paraffin and heat to 65°C until the paraffin is completely melted. Measure 30 g of tetramethyl titanate, mix it uniformly with molten paraffin under stirring, and cool while stirring to obtain a paraffin block dispersed with tetramethyl titanate. Put the paraffin block dispersed with tetramethyl titanate into water, and stir while heating at 65°C until the paraffin wax is completely melted. During the melting process, the tetramethyl titanate is slowly released and hydrolyzed with water to form a uniform dispersion. lotion. Then stand still and cool to room temperature, the emulsion appears to be separated, and the paraffin coagulates into blocks on the water surface, and the resulting flocculated solid slowly sinks to the bottom of the beaker, forming a precipitate. When no flocculated matter sinks, take out the wax block, centrifuge the remaining solution, dry the obtained solid naturally, and calcinate it in a muffle furnace at a temperature of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com