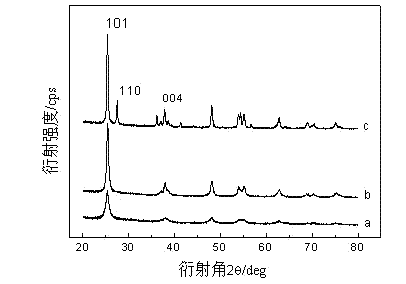

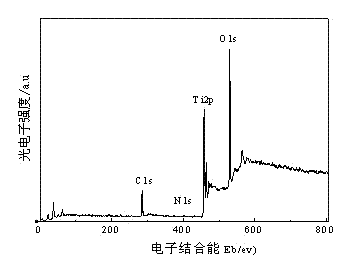

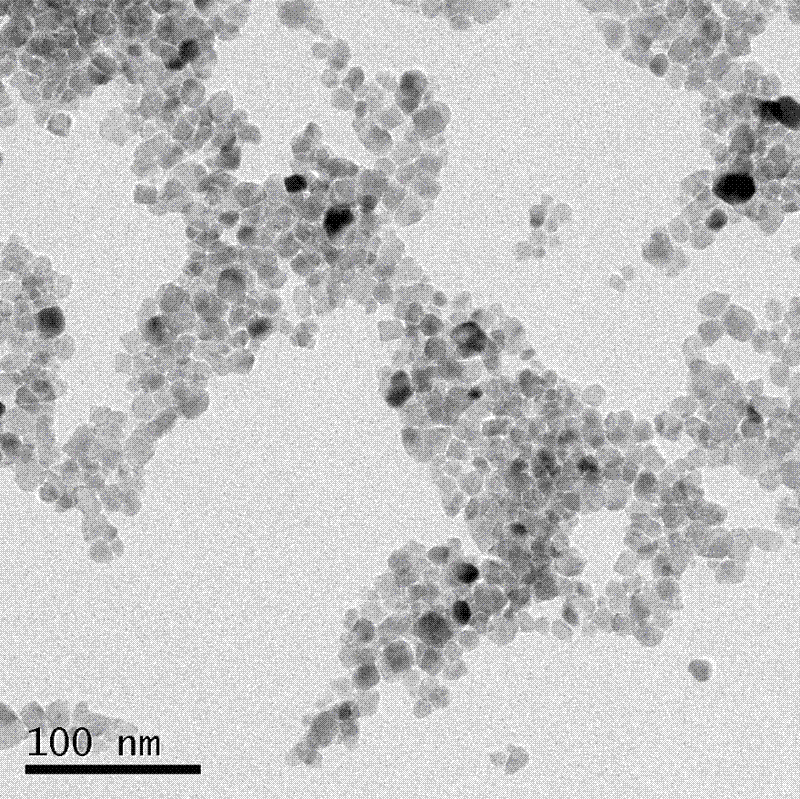

Method for preparing C-N-codoped nano-TiO2 powder

A co-doping, C-N technology, applied in the direction of nanotechnology, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of high equipment requirements, ineffective control of agglomeration problems, cumbersome preparation process of precursors, etc., to achieve The effect is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Butyl titanate and absolute ethanol were mixed evenly at a volume ratio of 1:6, and urea with a mass ratio of 0.5% was added at the same time, poured into the same beaker, and oscillated under an ultrasonic instrument for 3 minutes to fully dissolve the urea. Then magnetically stir and mix evenly to make a colorless and transparent mixed solution. After about 3 minutes, turn on the air pump switch, with 40 L·min -1 The air is delivered to the three-necked flask with a small amount of water at a rate of 100%, and the water vapor is brought into the beaker with a mixture of butyl titanate, ethanol and urea through another interface, and the quality of the water vapor delivered is controlled relative to the mixing. Liquid is 12.5g·L -1 , continue magnetic stirring, after 3 minutes, the mixed solution turns from colorless and transparent to turbid, and finally turns into a white emulsion, and the reaction stops after 40 minutes. Put the beaker containing the w...

Embodiment 2

[0018] Example 2: Butyl titanate and absolute ethanol are mixed evenly at a volume ratio of 1:8, and urea with a mass ratio of 0.8% is added at the same time, poured into the same beaker, stirred evenly in a stirrer until the urea is fully dissolved, and mixed Uniformly made into a colorless and transparent mixture. Then turn on the air pump switch, with 60 L·min -1 Air is delivered to a three-neck flask containing a small amount of water at a rate of 100%, and water vapor is brought into a beaker containing a mixture of butyl titanate, ethanol and urea through another interface, and the quality of water vapor delivered is controlled relative to the mixing Liquid is 17.5g·L -1 , continue magnetic stirring, after about 5 minutes, the mixed solution turns from colorless and transparent to turbid, and finally turns into a white emulsion, and the reaction stops after 45 minutes. Put the beaker containing the white emulsion into a blast drying oven, and let it stand at 40°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com