Method for producing enzymolysis dairy-type isolated soy protein and product thereof

A technology of soybean protein isolate and production method, which is applied to the production method of enzymatically hydrolyzed dairy-type soybean protein isolate and its products, and can solve the problems of failure to achieve the best use effect of the production process, reduction of harmful metabolite protein content, and anti-nutritional factors. Low removal rate and other issues, to achieve a wide range of industrial utilization value, nutritional improvement, and avoid the effects of protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

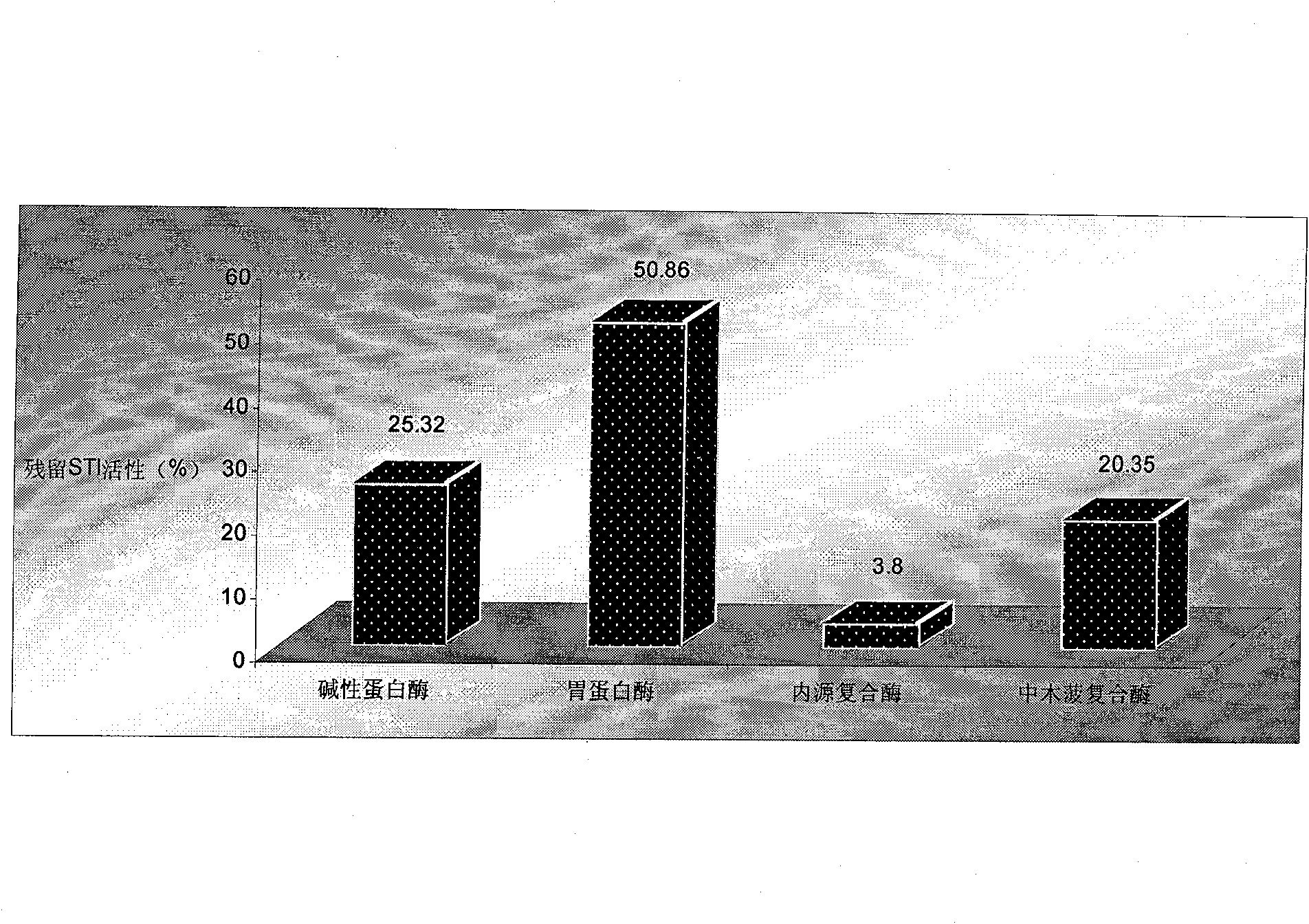

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will describe in detail the production method of an enzymatically hydrolyzed dairy-type soybean protein isolate and the specific details of its products in conjunction with the preferred embodiments and accompanying drawings. Embodiments, production methods, steps, features and effects thereof.

[0026] The present invention relates to a production method of enzymolysis dairy type soybean protein isolate and its products, which sequentially include the preparation of enzyme liquid, the extraction of soybean meal, the acid precipitation of extract liquid, the neutralization of acid precipitation sediment, the sterilization of neutralization liquid and the Concentration, enzymatic hydrolysis of the concentrated solution, and homogenization and drying steps of the enzymatic hydrolysis solution. Preferably, a product collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com