Foam glass composite air duct board and manufacturing method thereof

A foam glass and composite air duct technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem of affecting personnel escape, failing to meet the fire protection requirements of architectural design, and composite air duct plates are not suitable for application, etc. problems, to achieve the effect of good safety performance, long service life and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments.

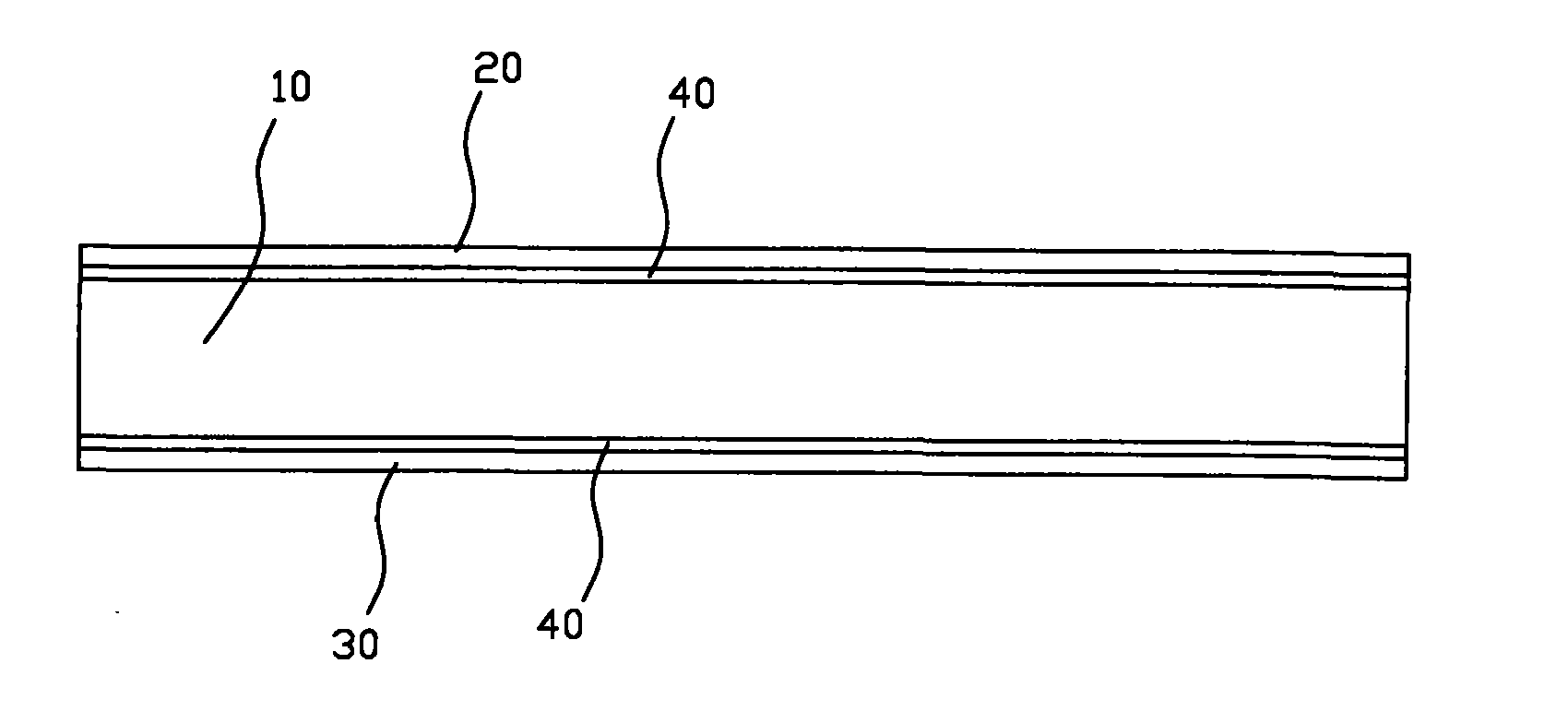

[0018] A foam glass composite air duct plate of the present invention is a sandwich structure, which includes a metal surface layer 20 as the outer surface of the air duct, a fireproof or anti-corrosion surface layer 30 as the inner surface of the air duct, and a foam glass layer as the core material 10. The three are tightly adhered together through two adhesive layers 40 .

[0019] When manufacturing a foam glass composite air duct plate of the present invention, block foam glass is first cut into sheets with a thickness of 10-100 mm, and after trimming, small-sized sheets are spliced into continuous sheets with a width of 1200 mm ; The roll-type metal surface layer 20 and the fireproof or anti-corrosion surface layer 30 are fed at a constant speed and rolled to coat the adhesive layer 40. After heating and drying, they are directly pasted and compounded with the foam glass sheet 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com