Method for preparing nanometer silver halide colloids

A silver halide and nanotechnology, which is applied in the field of preparation of nanometer silver halide colloids, can solve the problems of difficulty in product purification, increased cost, complicated methods, etc., and achieves the effects of uniform microscopic morphology and size, stable dispersion, and simple and controllable steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

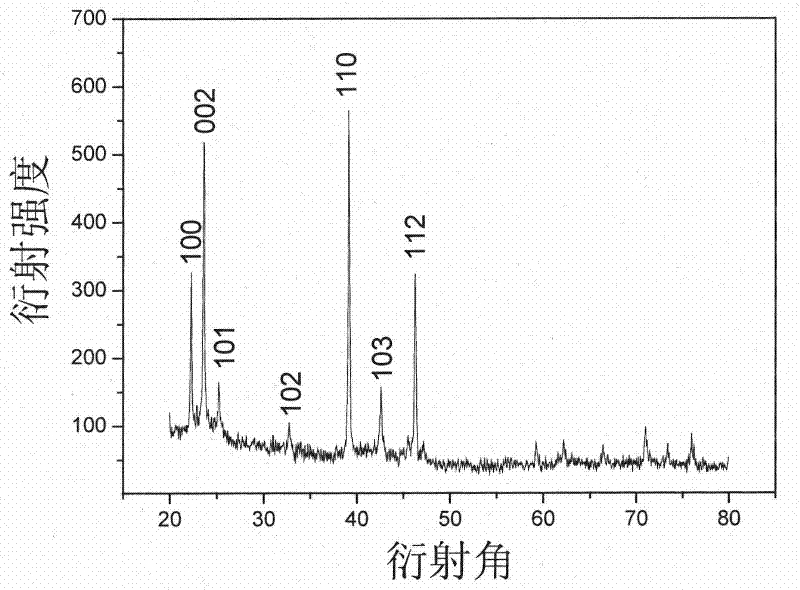

[0028] Weigh 10 g of solid paraffin, put it into 200 mL of deionized water heated to 70° C., control the temperature, and stir to completely melt the paraffin. Weigh a certain amount of KI and AgNO 3 , were formulated with a concentration of 0.06mol·L -1 The aqueous solution, using the method of double drops, is added to the above-mentioned paraffin / water microemulsion at a speed of 15 drops / min, temperature control, stirring, so that the system is uniformly dispersed, and kept for 20 minutes after the end of the dropwise addition, then stop the temperature control Stir, let the resulting mixed microemulsion stand, and cool to room temperature naturally. As the temperature decreases, the microemulsion will be stratified, and the paraffin will condense into blocks on the water surface. Take out the wax block completely, and add polyethylene to the remaining microemulsion. Pyrrolidone dispersant, continue to stir for 30 minutes to obtain a light yellow AgI colloid, which does n...

Embodiment 2

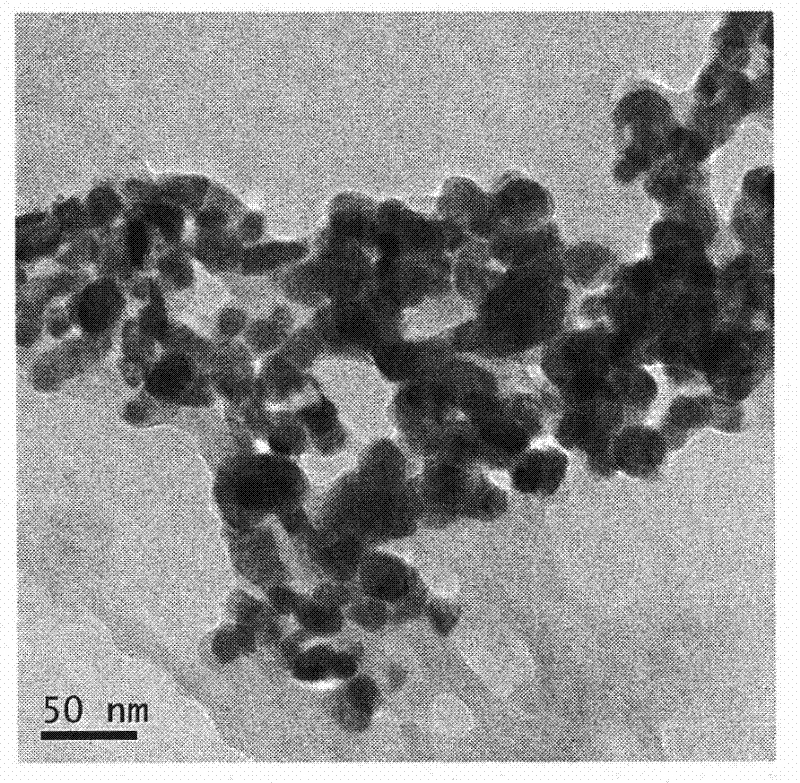

[0032] Weigh 10 g of solid paraffin, put it into 250 mL of deionized water heated to 90° C., control the temperature, and stir to completely melt the paraffin. Weigh a certain amount of KCl and AgNO 3 , were formulated with a concentration of 0.03mol·L -1 The aqueous solution of the above-mentioned paraffin wax microemulsion is added into the above-mentioned paraffin microemulsion at a rate of 10 drops / minute by double-drop method, temperature controlled, stirred to make the system uniformly dispersed, and kept for 10 minutes after the dropwise addition, then stop the temperature control and stir, Gained microemulsion is left to stand, naturally cooled to room temperature, along with the reduction of temperature, microemulsion stratification occurs, and paraffin coagulates into a block on the water surface, the wax block is taken out completely with tweezers, and 2g carboxymethyl is added in the remaining microemulsion Sodium sulfonate dispersant, continue to stir for 30 minu...

Embodiment 3

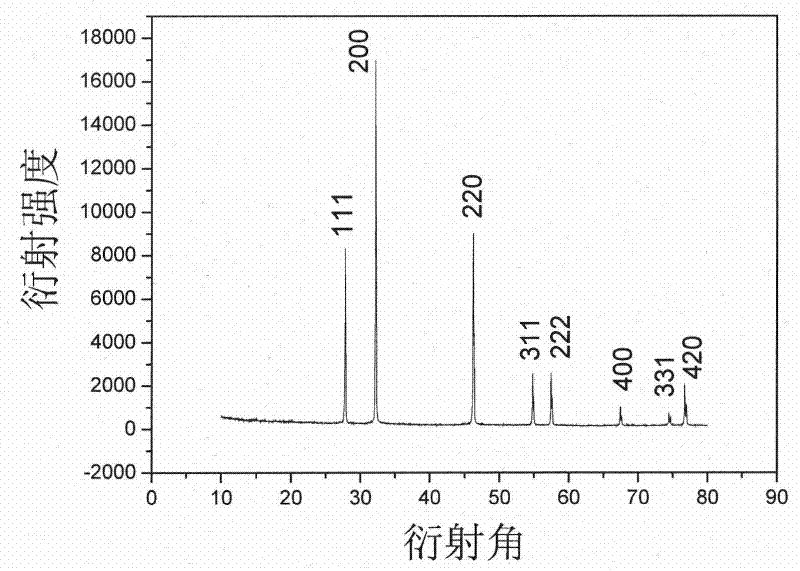

[0036] Weigh 10 g of solid paraffin, put it into 220 mL of deionized water heated to 80° C., control the temperature, and stir to completely melt the paraffin. Weigh a certain amount of KBr and AgNO 3 , were formulated with a concentration of 0.05mol·L -1 The aqueous solution of the above-mentioned paraffin wax microemulsion is added into the above-mentioned paraffin microemulsion with a speed of 18 drops / min by the method of double drops, and the temperature is controlled and stirred to make the system uniformly dispersed. The obtained microemulsion was allowed to stand, and naturally cooled to room temperature. As the temperature decreased, the microemulsion layered, and the paraffin wax coagulated into a block on the water surface. The wax block was completely taken out, and 1g of alkylphenol was added to the remaining microemulsion. Polyoxyethylene ether dispersant, continue to stir for 30 minutes to obtain milky white AgBr colloid, which does not decompose when exposed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com