Sugar-coated chewing gum composition and method for producing sugar-coated chewing gum

A manufacturing method and technology of chewing gum, applied in chewing gum, biochemical equipment and methods, food preparation, etc., can solve the problems of unsatisfactory high effect of lactoferrin, time required, poor preparation storage stability, etc., and achieve long-term Excellent storage stability, fast chewing release speed, and excellent inactivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

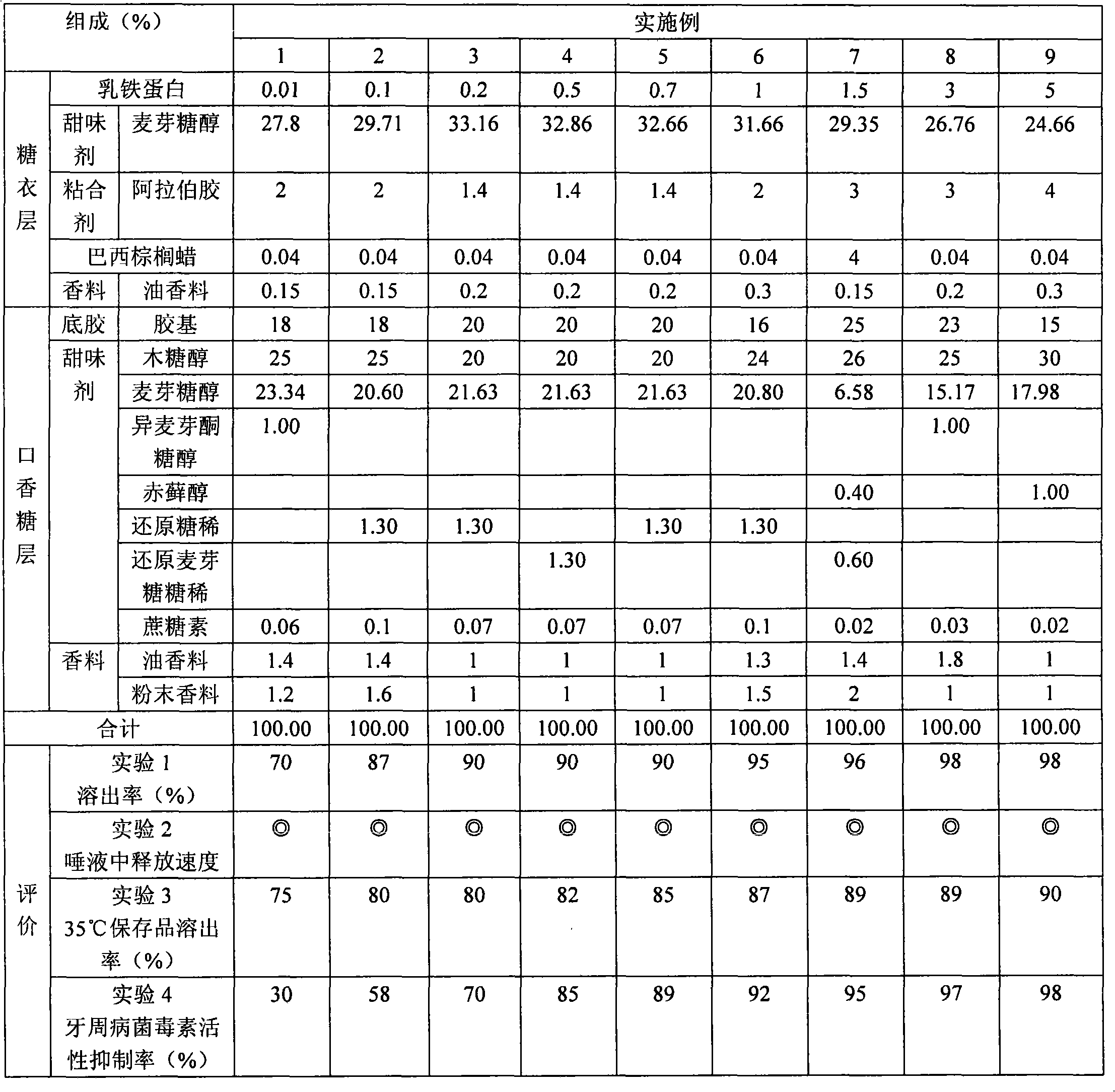

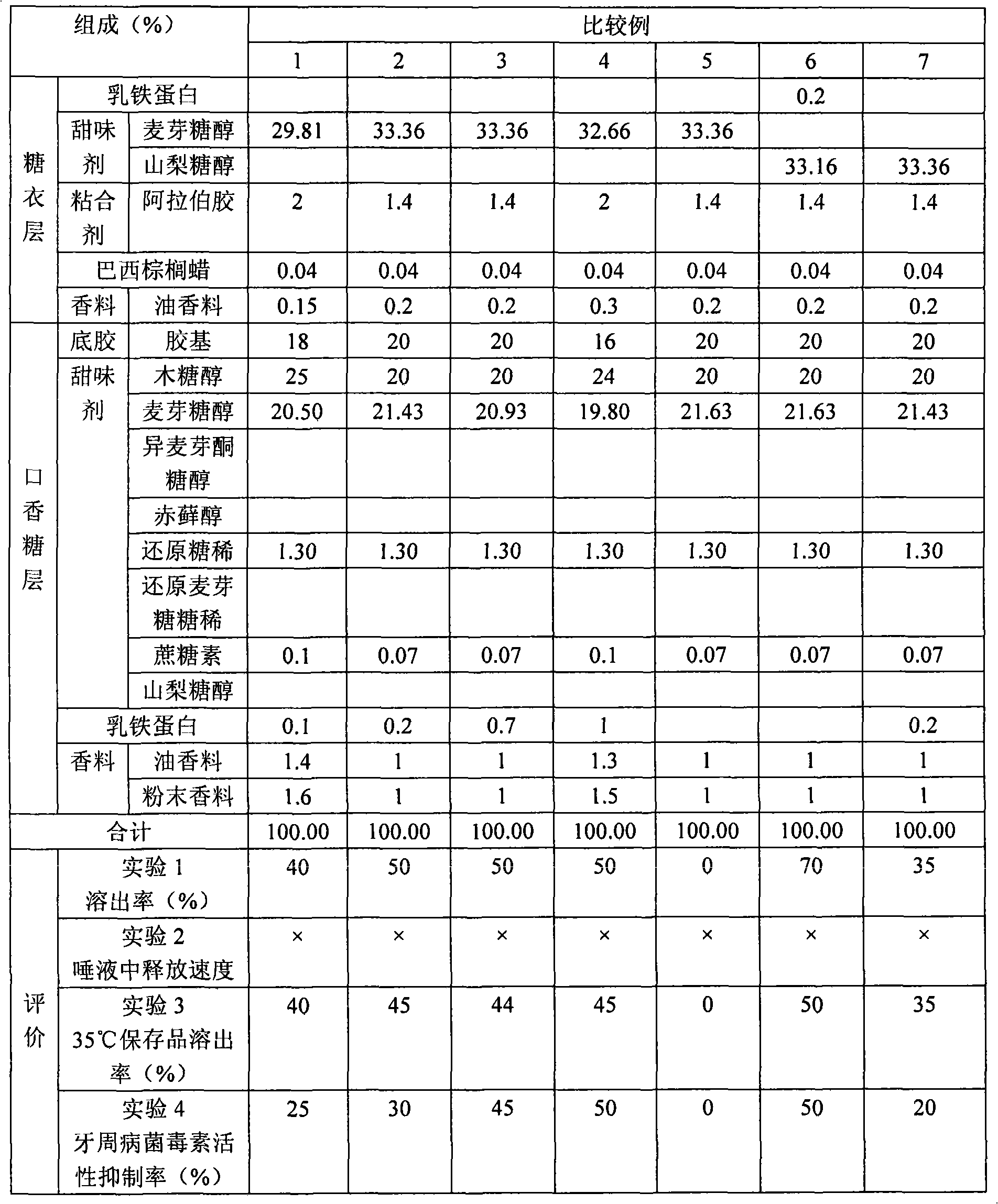

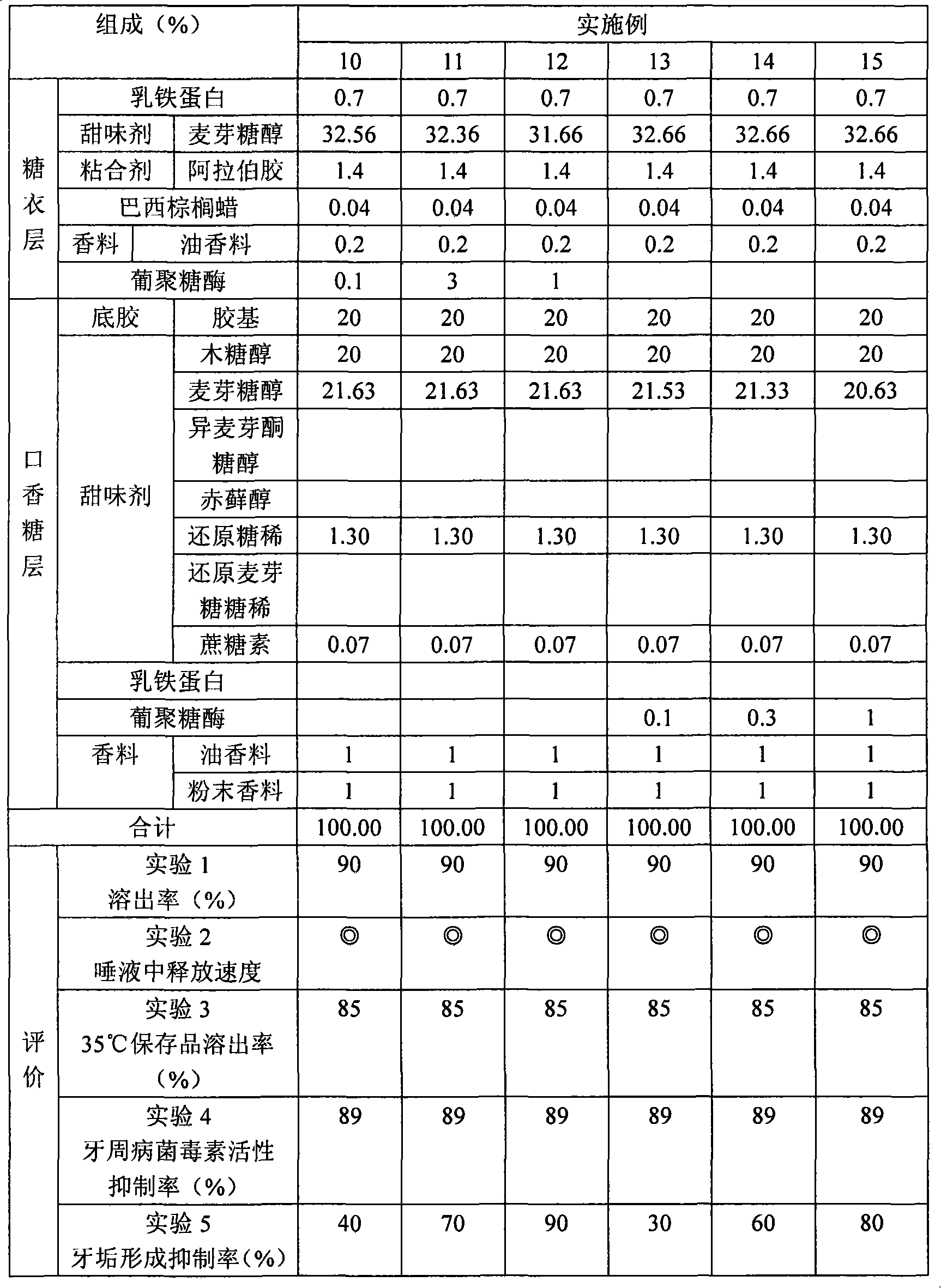

[0055] Hereinafter, the present invention will be described in more detail through experimental examples, examples, and comparative examples, but the present invention is not limited by the following examples. In addition, % in each example is mass % unless otherwise specified, and the compounding quantity is the quantity converted into the pure component after drying except water|moisture content.

experiment example

[0057] Sugar-coated chewing gums having the compositions shown in Tables 1 to 3 were prepared by the following method and evaluated by the following method. The results are shown in Tables 1-3.

[0058] Preparation of sugar-coated chewing gum:

[0059]According to the compositions shown in Tables 1 to 3, gum base (manufactured by Nathural Beers Co., Ltd.), xylitol (manufactured by Mitsubishi Corporation Fudotec Co., Ltd.), maltitol (manufactured by Mitsubishi Corporation Fudotec Co., Ltd.) were added. ), isomalt (manufactured by Mitsui Sugar Co., Ltd.), erythritol (manufactured by Nikken Chemical Co., Ltd.), reduced syrup (manufactured by Nikken Chemical Co., Ltd.), reduced maltose syrup (manufactured by Nikken Chemical Co., Ltd. Co., Ltd.), dextranase (12,000 units, manufactured by MFC Lighttec Co., Ltd.), sucralose (manufactured by Sanei Gen EFEFAI Co., Ltd.), powder flavor, oil flavor, use a 1L-capacity kneader around 50°C (manufactured by Toshin Co., Ltd.) and kneaded un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com