Rumen protected methionine and production method thereof

A methionine, rumen-passing technology, applied in the direction of animal feed, additional food elements, animal feed molding or processing, etc., can solve the problems of unreasonable process, low methionine content, uneven coating, etc., to improve milk production of dairy cows and milk protein content, high methionine content, uniform and complete coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

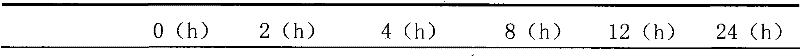

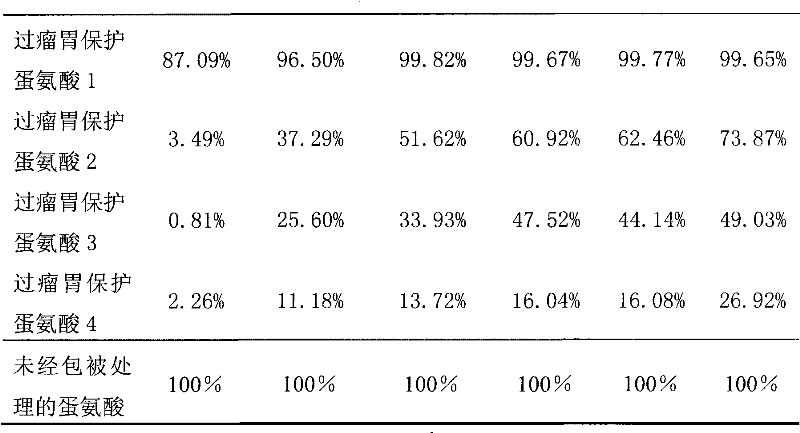

[0038] Example 1. Preparation of Rumen Protected Methionine 1

[0039] 1. Preparation of Methionine Granules

[0040] Methionine, dextrin and microcrystalline cellulose are mixed in proportion to obtain a mixture. In the mixture, the mass proportion of methionine is 94.4%, the mass proportion of dextrin is 1.1%, and the mass proportion of microcrystalline cellulose is It is 4.5%, and then the mixture is prepared with water into a state that can be granulated, and the granules are prepared with a granulator, and then shot with a spherical shot blasting machine to obtain methionine granules.

[0041] 2. Drying of methionine particles

[0042] Put the methionine granules prepared in step 1 into a fluidized granulating and coating machine for drying. The heating temperature of the equipment is 80℃, the induced air frequency is 35Hz, the rotation speed is 45Hz, and the drying is 30 minutes. It is then sieved with 30 mesh and 40 mesh sieves to obtain dry methionine particles with a partic...

Embodiment 2

[0046] Example 2: Preparation of Rumen Protected Methionine 2

[0047] 1. Preparation of Methionine Granules

[0048] Methionine, dextrin and microcrystalline cellulose are mixed in proportions to obtain a mixture. The mass proportion of methionine in the mixture is 92.9%, the mass proportion of dextrin is 1.4%, and the mass proportion of microcrystalline cellulose is 5.7%. Then the mixture is prepared into a state that can be granulated with water. The granulator is used to prepare granules, and then shot with a spherical shot blasting machine to obtain methionine granules.

[0049] 2. Drying of methionine particles

[0050] Put the methionine granules prepared in step 1 into a fluidized granulation coating machine for drying. The heating temperature of the equipment is 80℃, the induced air frequency is 35Hz, the rotation speed is 45Hz, and the drying is 30 minutes. Then sieved with 30 mesh and 40 mesh sieves to obtain dry methionine particles with a particle size greater than or ...

Embodiment 3

[0054] Example 3. Preparation of Rumen Protected Methionine 3

[0055] 1. Preparation of Methionine Granules

[0056] Methionine, dextrin and microcrystalline cellulose are mixed in proportions to obtain a mixture. The mass ratio of methionine in the mixture is 91.7%, the mass ratio of dextrin is 1.6%, and the mass ratio of microcrystalline cellulose is 6.7%. Then the mixture is prepared into a state that can be granulated with water. Granules are prepared by a granulator, and then shot with a spherical shot blasting machine to obtain methionine granules.

[0057] 2. Drying of methionine particles

[0058] Put the methionine granules prepared in step 1 into a fluidized granulation coating machine for drying. The heating temperature of the equipment is 80℃, the induced air frequency is 35Hz, the rotation speed is 45Hz, and the drying is 30 minutes. Then sieved with 30 mesh and 40 mesh sieves to obtain dry methionine particles with a particle size greater than or equal to 0.40 mm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com