Mn-Co-doped spinel composite nanometer material and low-temperature sintering method thereof

A technology of composite nanomaterials and low-temperature sintering, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of expensive film formation methods, difficulty in preventing the diffusion and volatilization of Cr oxides, difficulty in sintering and compaction, etc., and achieve high-temperature conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

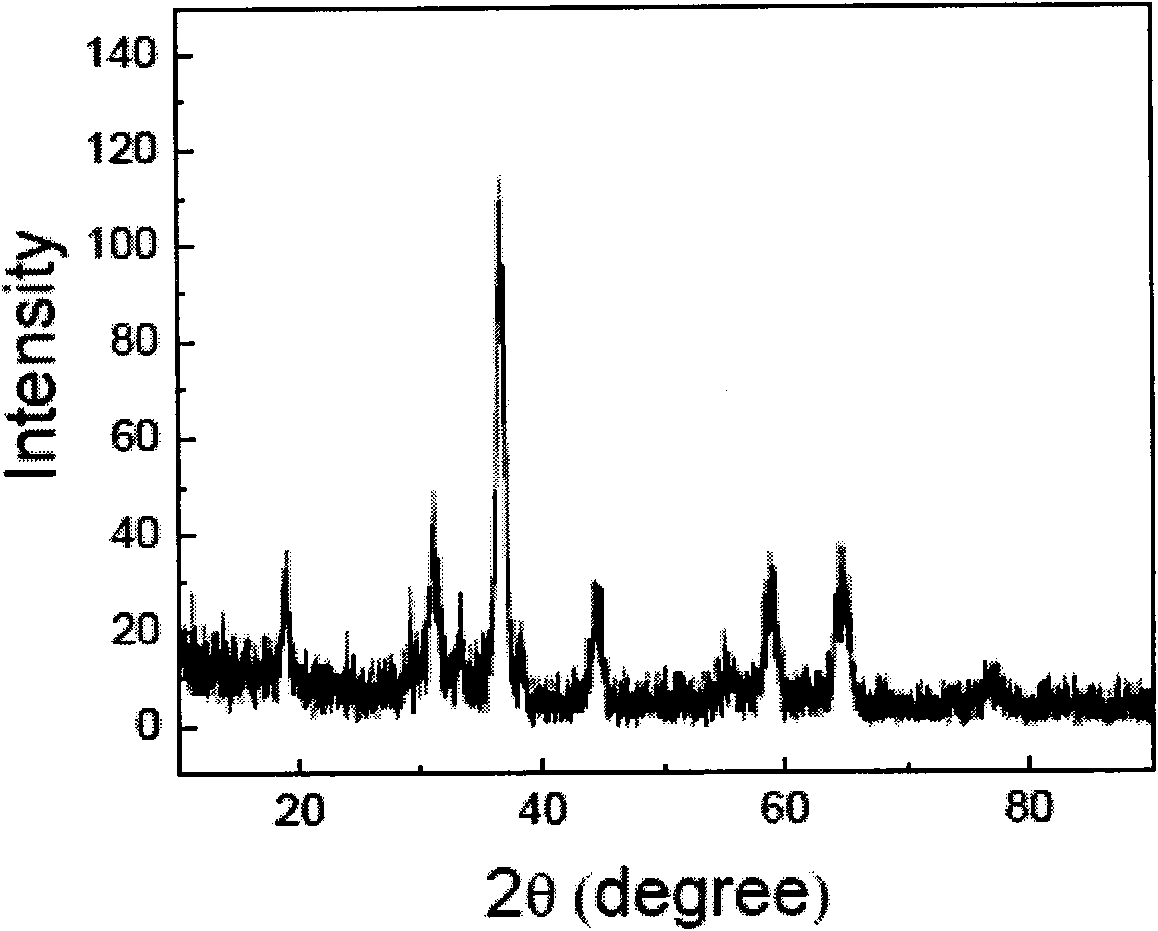

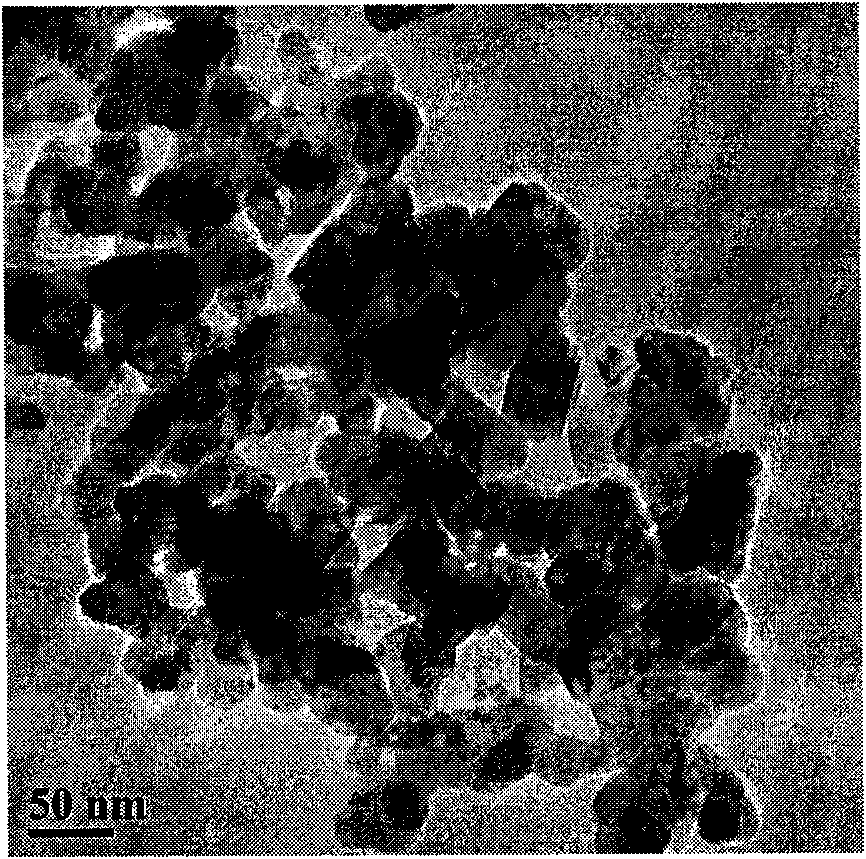

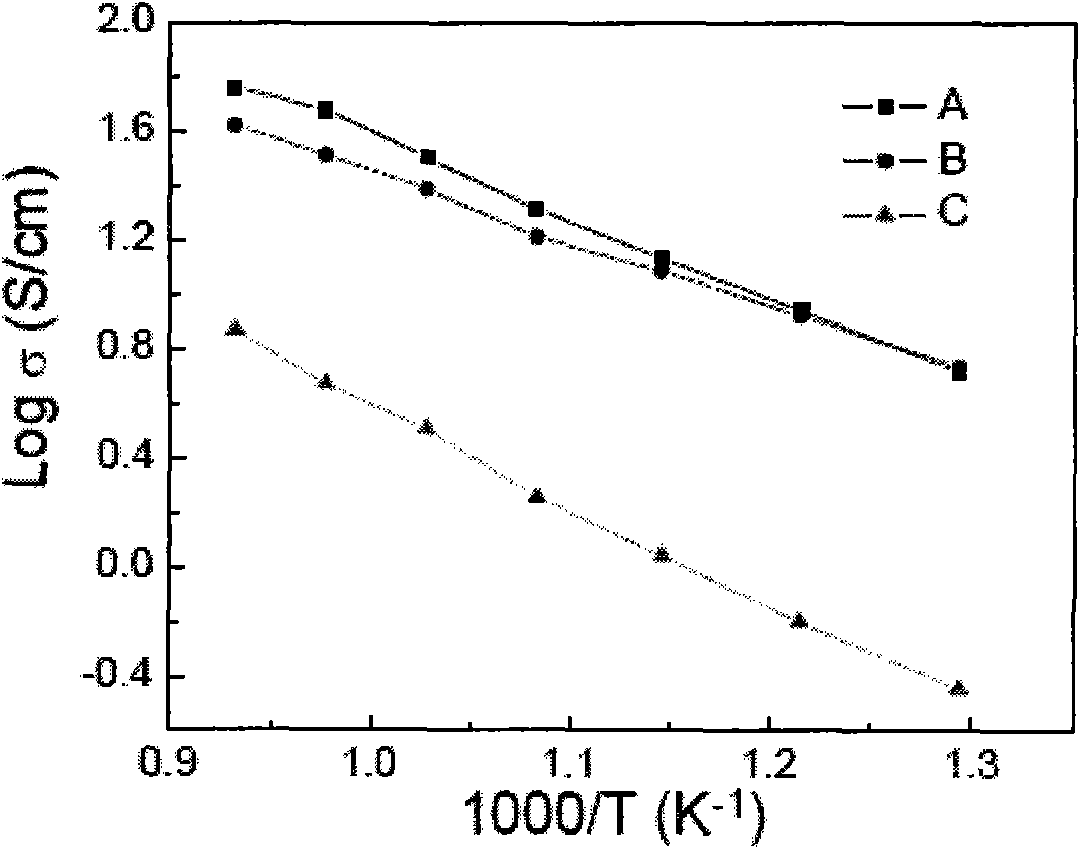

[0033] Embodiment 1 nanometer powder material Mn 0.9 Y 0.1 co 2 o 4 Preparation and low temperature sintering method

[0034] 1. Preparation of nano-powder material Mn by sol-gel method 0.9 Y 0.1 co 2 o 4 : (i) the nitrate of Y, Mn and Co is dissolved in deionized water at a ratio of 0.1:0.9:2 in the molar ratio of Y ions, Mn ions and Co ions, wherein Y ions, Mn ions and Co ions total The molar concentration is 1mol / L; add citric acid and ethylene glycol that are 3 times the total molar weight of Y ions, Mn ions and Co ions, mix and stir evenly, wherein the molar ratio of citric acid to ethylene glycol is 2:1; The solution was heated and volatilized at 75°C to form a sol; (ii) the above sol was further dried in an oven at 180°C to expand and solidify into a xerogel; (iii) the xerogel was calcined at 700°C, and then further dried in an oven without Ball milling in water and ethanol and drying to obtain Mn 0.9 Y 0.1 co 2 o 4 Powder material.

[0035] The above-prepa...

Embodiment 2

[0039] Embodiment 2 nanometer powder material Mn 0.8 Y 0.2 co 2 o 4 Preparation and low temperature sintering method

[0040] The difference between this example and Example 1 is that the acetates of Y, Mn and Co are dissolved in deionized water at a molar ratio of Y ions, Mn ions and Co ions at a ratio of 0.2:0.8:2. Other steps are the same as Embodiment 1.

Embodiment 3

[0041] Embodiment 3 nanometer powder material Mn 2 co 0.9 Y 0.1 o 4 Preparation and low temperature sintering method

[0042] 1. Preparation of nano-powder material Mn by combustion method 2 co 0.9 Y 0.1 o 4 : (i) the acetate of Y, Mn and Co is dissolved in deionized water at a ratio of 0.1: 2: 0.9 in the molar ratio of Y ions, Mn ions and Co ions; add 2 times the amount of Y ions, Mn ions and Glycine with the total molar amount of Co ions is mixed and stirred evenly; (ii) the above solution is heated and volatilized in an electric furnace to form a gel until it is burned to obtain a precursor; (iii) the precursor is calcined at 750 ° C, and then further in anhydrous Ball milling in ethanol and drying to obtain Mn 2 co 0.9 Y 0.1 o 4 Powder material.

[0043] 2. Low-temperature sintering process: the above-prepared Mn 2 co 0.9 Y 0.1 o 4 The powder material is subjected to reduction treatment at 650°C in a carbon monoxide atmosphere, pressed into tablets after co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com