Method for preparing loaded and non-loaded Cu3P by adopting copper oxide precursor reduction method

A copper oxide, non-supported technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, phosphides, etc., can solve the problems of limited application and inability to prepare Cu3P, and achieve low preparation temperature, low cost, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

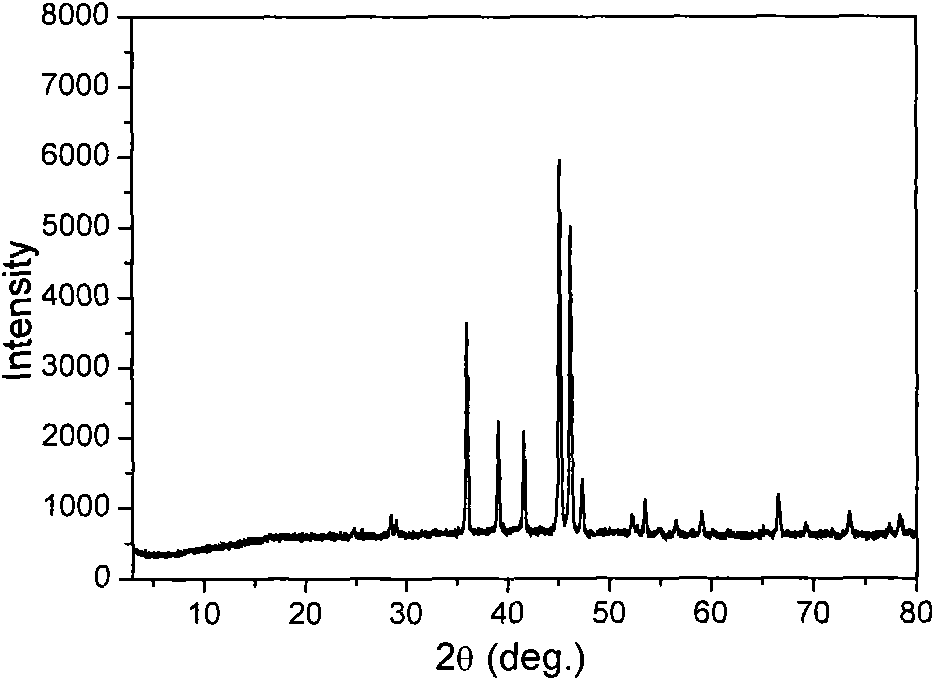

[0016] First, 10.71 g of NaH was mixed with stirring at room temperature 2 PO 2 .H 2 O was added to 27 mL of deionized water, dissolved for 10 min, and then 1.59 g of CuO was added. After stirring for 1 h, the resulting solution was put into a Petri dish and dried at 40 °C. The dried precursor powder was loaded into the reactor, and heat-treated at 300° C. for 20 min in a static nitrogen protective atmosphere. Then the obtained product is washed with water, pickled and then dried, and the obtained sample is named A, and A has an attached figure 1 Characteristics.

Embodiment 2

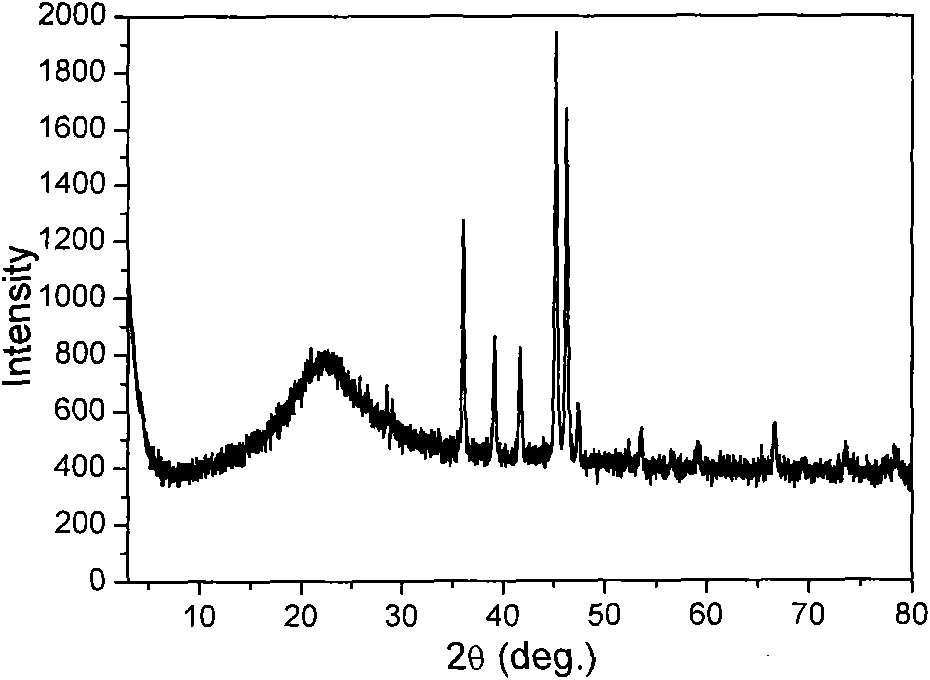

[0018] First, 2.43g of copper nitrate was added to 13mL of deionized water under stirring at room temperature, and after dissolving for 10min, 2.12g of MCM-41 molecular sieves were added. After continuing to stir for 1 hour, the resulting solution was put into a petri dish and dried at 100°C. Put the dried precursor powder into a muffle furnace, and bake it at 500° C. for 2 hours in an air atmosphere to obtain supported copper oxide (CuO / MCM-41). With stirring at room temperature, 4.82 g of NaH 2 PO 2 .H 2 O was added to 13 mL of deionized water, and after dissolving for 10 min, the supported copper oxide (CuO / MCM-41) was added. After continuing to stir for 1 hour, the resulting solution was put into a petri dish and dried at 80°C. The dried precursor powder was loaded into the reactor, and heat-treated at 400° C. for 20 min in a static nitrogen protective atmosphere. Then the obtained product is washed with water, pickled and dried, and the obtained sample is named as B,...

Embodiment 3

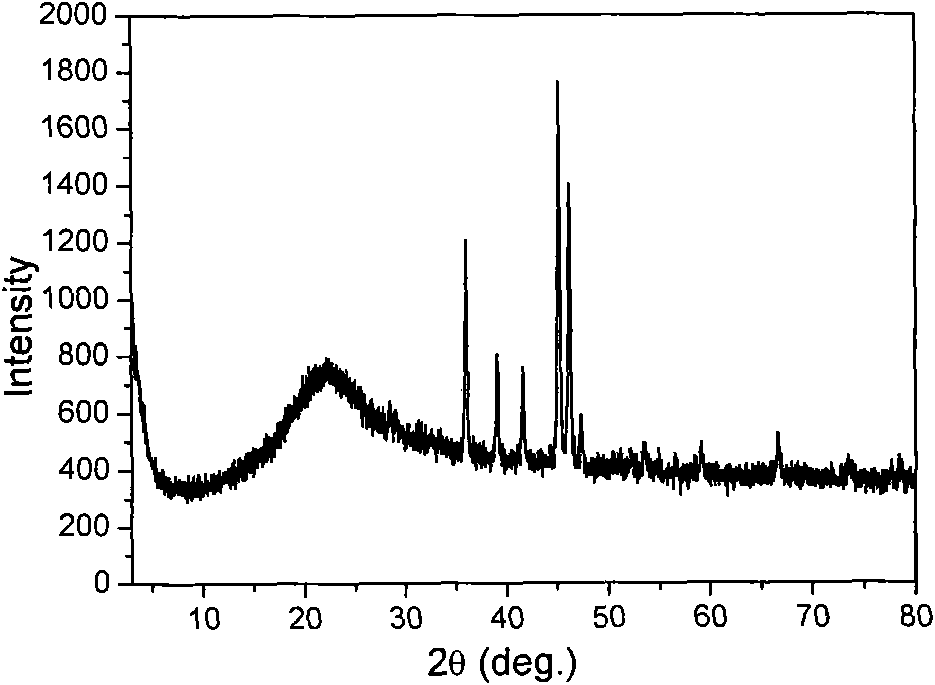

[0020] The preparation process is the same as that of sample B, only changing the NaH 2 PO 2 .H 2 The amount of O is 5.35g, and other conditions remain unchanged. The obtained sample was named C, and C has attached image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com