Calcium silicate multi-level nano-structure mesoporous microsphere and preparation method thereof

A nanostructure, calcium silicate technology, applied in the direction of silicate, alkaline earth metal silicate, inorganic non-effective ingredients, etc., to achieve the effect of cheap raw materials, simple preparation process, uniform shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

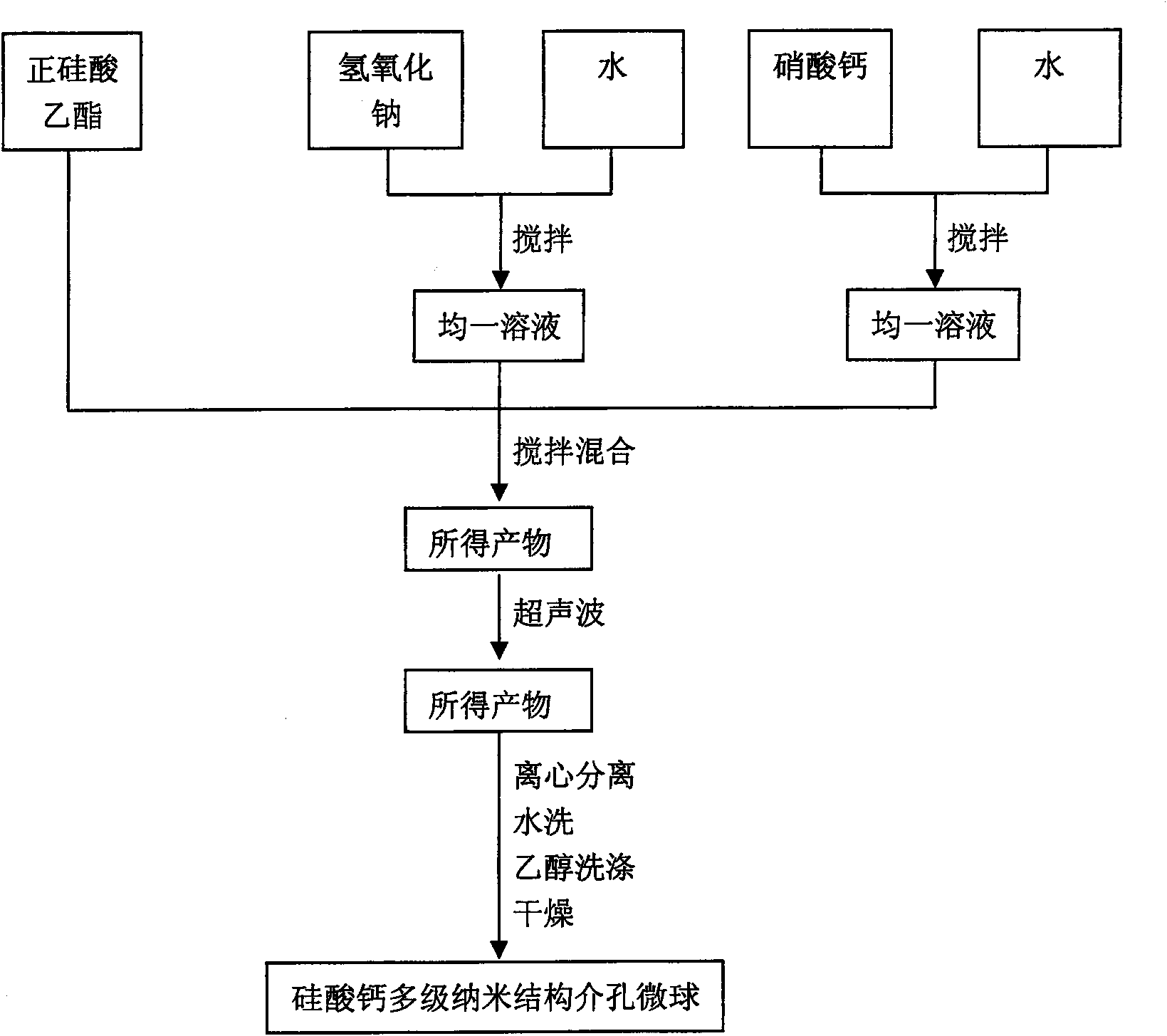

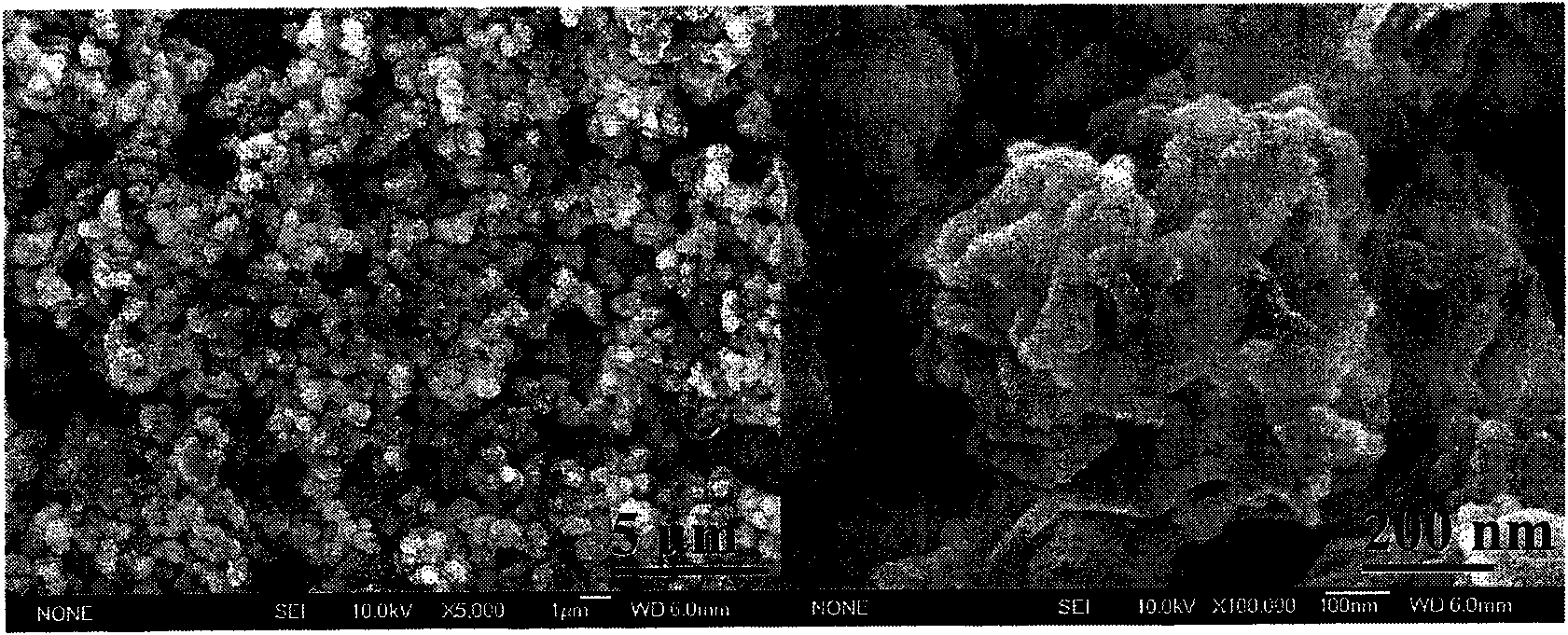

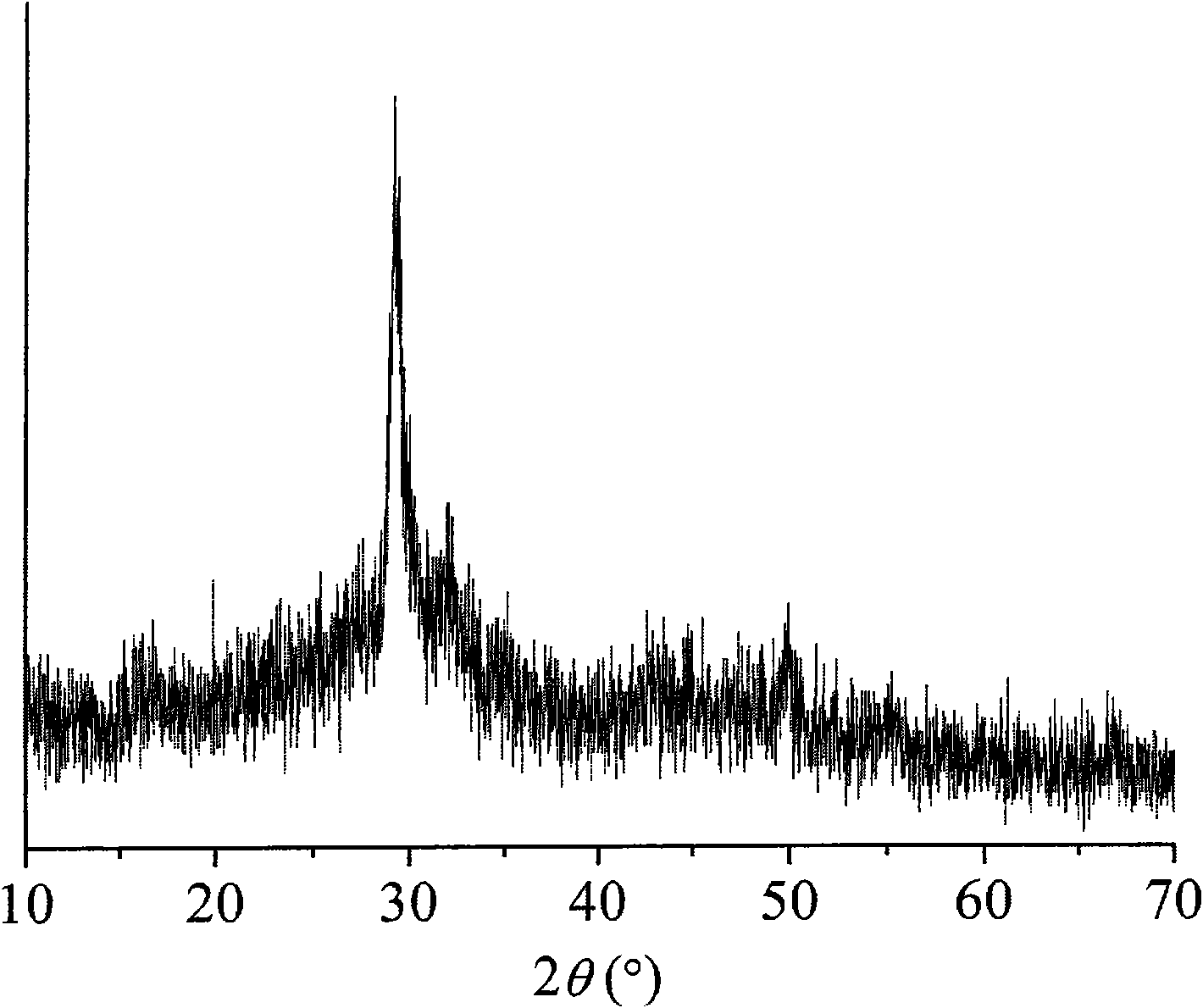

[0035] Preparation of Calcium Silicate Hierarchical Nanostructured Mesoporous Microspheres

[0036] Prepare NaOH aqueous solution with a concentration of 1mol / L and Ca(NO 3 ) 2 aqueous solution. At room temperature, under the condition of stirring, to 65mL concentration of 0.046mol / L Ca(NO 3 ) 2 Add 5 mL of 1 mol / L NaOH aqueous solution and 0.34 mL of ethyl silicate in sequence to the aqueous solution to obtain an emulsion. Then the ultrasonic probe was immersed in the emulsion, and the ultrasound was applied for 20 minutes under the power of 400W. After the reaction, the product was separated by centrifugation, and the separated product was washed three times with deionized water and ethanol, and dried in an air atmosphere at 60° C. to obtain calcium silicate multi-level nanostructured mesoporous microspheres.

Embodiment 2

[0038] Preparation of Calcium Silicate Hierarchical Nanostructured Mesoporous Microspheres

[0039] Prepare NaOH aqueous solution with a concentration of 1mol / L and Ca(NO 3 ) 2 aqueous solution. At room temperature, under the condition of stirring, to 65mL concentration of 0.046mol / L Ca(NO 3 ) 2 Add 10 mL of 1 mol / L NaOH aqueous solution and 0.34 mL of ethyl silicate in sequence to the aqueous solution to obtain an emulsion. Then the ultrasonic probe was immersed in the emulsion, and the ultrasound was applied for 20 minutes under the power of 400W. After the reaction, the product was separated by centrifugation, and the separated product was washed three times with deionized water and ethanol, and dried in an air atmosphere at 60° C. to obtain calcium silicate multi-level nanostructured mesoporous microspheres.

Embodiment 3

[0041] Preparation of Calcium Silicate Hierarchical Nanostructured Mesoporous Microspheres

[0042] Prepare NaOH aqueous solution with a concentration of 1mol / L and Ca(NO 3 ) 2 aqueous solution. At room temperature, under the condition of stirring, to 65mL concentration of 0.046mol / L Ca(NO 3 ) 2 Add 3 mL of 1 mol / L NaOH aqueous solution and 0.34 mL of ethyl silicate in sequence to the aqueous solution to obtain an emulsion. Then the ultrasonic probe was immersed in the emulsion, and the ultrasound was applied for 20 minutes under the power of 400W. After the reaction, the product was separated by centrifugation, and the separated product was washed three times with deionized water and ethanol, and dried in an air atmosphere at 60° C. to obtain calcium silicate multi-level nanostructured mesoporous microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com