Silicate scale clearing agent for ternary combination flooding extraction well

A ternary compound and silicate technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of production current fluctuation, rise, broken rod, etc., and achieve the effect of ensuring construction effect and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

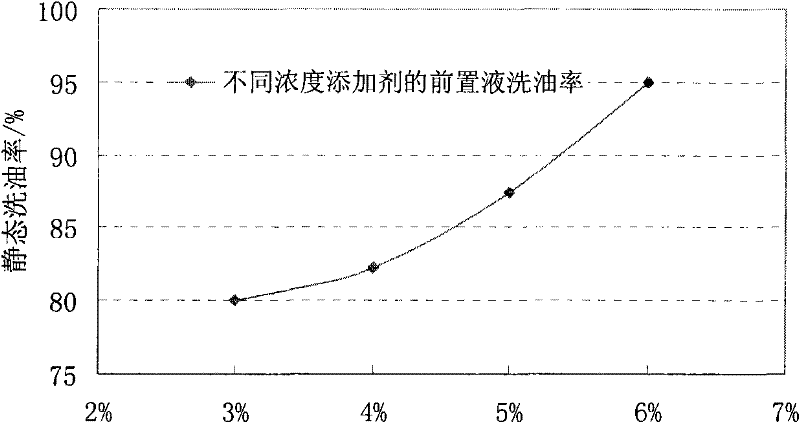

[0017] Example 1. Determination of the oil washing rate of pre-flush with different concentrations of SYQ-II: Mix the washed and dried quartz sand with the crude oil and bentonite in the ASP flooding block of Daqing Oilfield with a mass ratio of 10:5:1. Made into oil sands. Take 50ml of pre-liquid containing different concentrations of SYQ-II and add it to a plastic beaker, keep the temperature constant for 30 minutes, add 5g of oil sand, react for 3 hours, remove the solution, dry it in air, weigh it, and calculate the oil washing rate according to the following formula. The experimental results are shown in Table 1

[0018] Calculation formula of oil washing rate:

[0019] R=[(W 1 -W 2 ) / W 0 ]×100%

[0020] In the formula: R-oil washing rate, %;

[0021] W 1 - mass of oil sand before reaction, g;

[0022] W 2 - mass of oil sand after reaction, g;

[0023] W 0 - mass of oil before reaction, g.

[0024] Prefluid static oil washing rate Table 1

[0025] ...

Embodiment 2

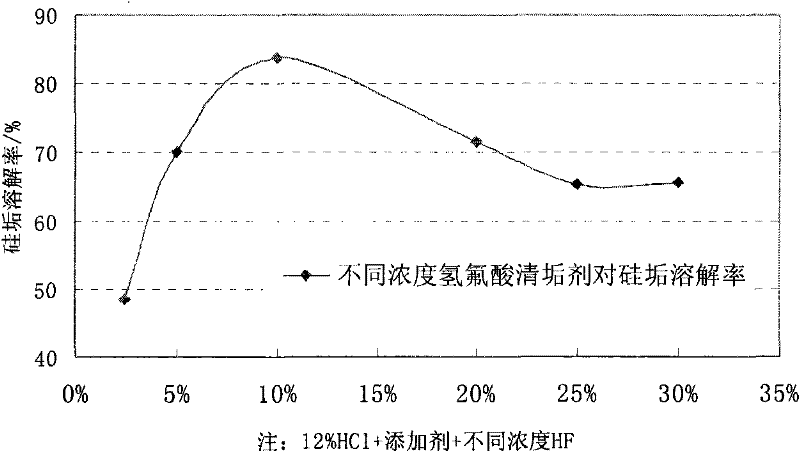

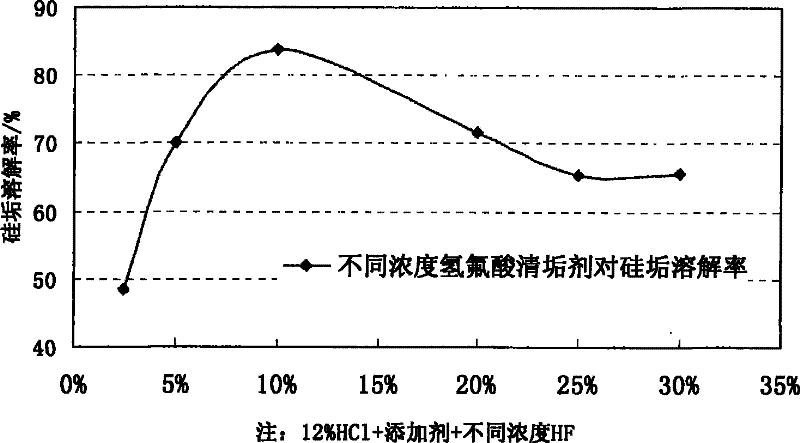

[0027] Example 2, Descaling rate measurement of descaling agents with different concentrations of HF acid: use 12% hydrochloric acid, 2% glacial acetic acid, 0.2% citric acid, 0.5% imidazoline type corrosion inhibitor in a 100ml plastic beaker (YC-II) and the rest of the water to prepare 50ml of descaling agent with different concentrations of hydrofluoric acid. The above items are all calculated by mass percentage. Take about 500g of scale samples from the South 5 Sanyuan Block of Daqing Oilfield, dry them in an oven at 115°C for 3 hours, take them out and cool them in a desiccator to room temperature, weigh 6 parts of 5g±0.1g scale samples, and add them to the above preparation React for 3 hours, then filter, dry in an oven at 115°C for 3 hours, take it out and cool it to room temperature in a desiccator, weigh the weight of the scale after the reaction, and calculate the scale according to the following formula The experimental results are shown in Table 2.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com