Erasable metal-insulator-silicon capacitor structure

A technology of silicon capacitors and insulators, applied in the field of capacitors, can solve the problems of reducing device erasing efficiency, achieve fast programming/erasing characteristics, large storage windows, and improve storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further specifically described below by way of examples.

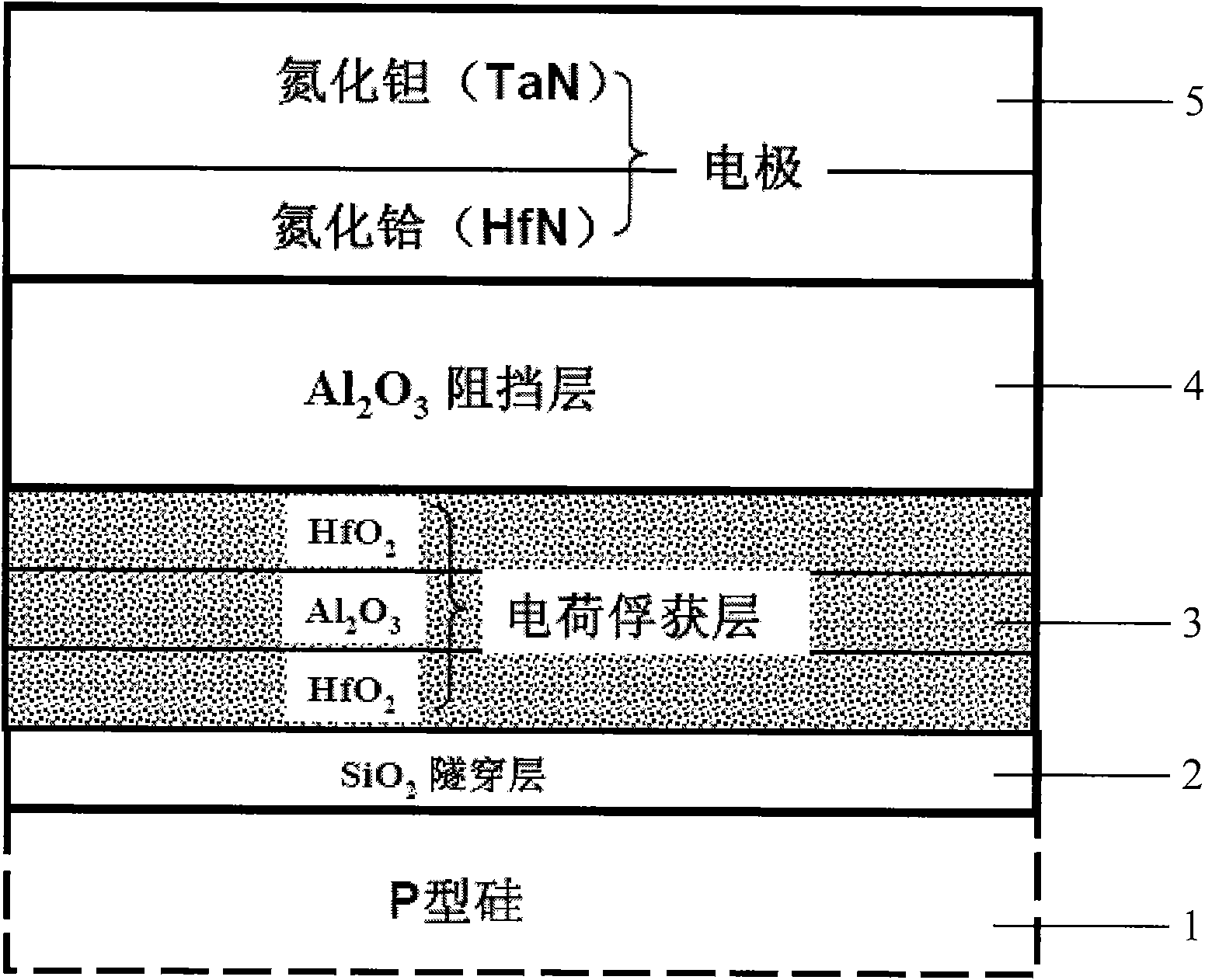

[0026] SiO is thermally oxidized in a dry oxygen atmosphere at 750-900°C 2 Make a charge tunneling layer with a physical thickness of 2-4 nanometers; then use atomic layer deposited HfO 2 / Al 2 o 3 / HfO 2 Sandwich nano-lamination as charge trapping layer, in which HfO 2 The physical thickness of the single layer is 1-3 nm, Al 2 o 3 The physical thickness of a single layer is 1-3 nanometers, and the physical thickness of the entire HAN layer is 3-9 nanometers; 2 o 3 As a barrier layer, its physical thickness is controlled at 6-12 nanometers, and high-temperature annealing after deposition is not required. Finally, the magnetron sputtered double-layer HfN / TaN is used as the metal electrode, in which HfN is directly connected with the charge blocking layer Al 2 o 3 touch.

[0027] The specific process steps are as follows:

[0028] (1) Perform standard RCA cleaning on the 4-8Ωcm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com