Micro solid-state laser module

A laser module and solid-state technology, which is applied to lasers, laser components, devices for controlling laser output parameters, etc., can solve problems such as low conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

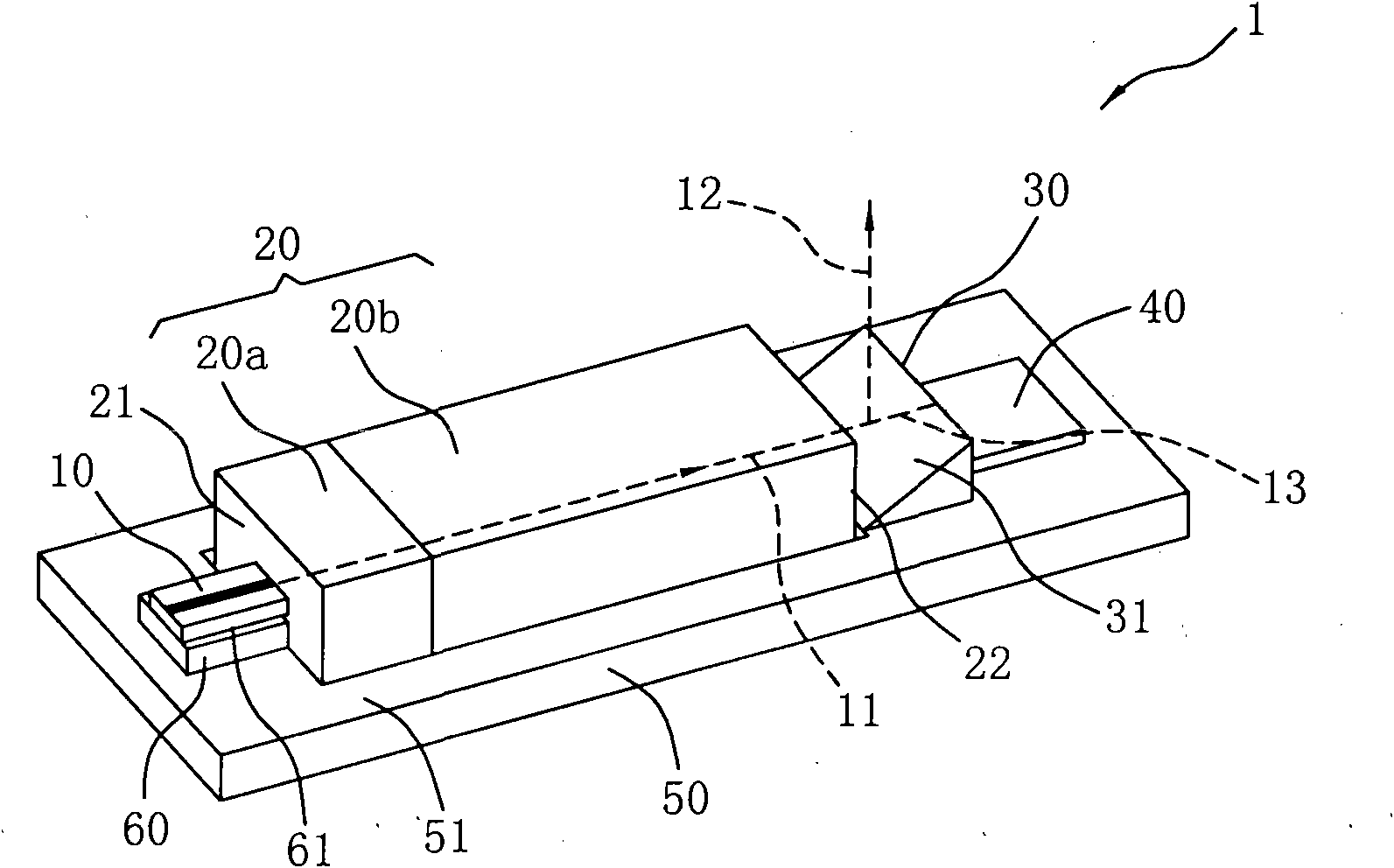

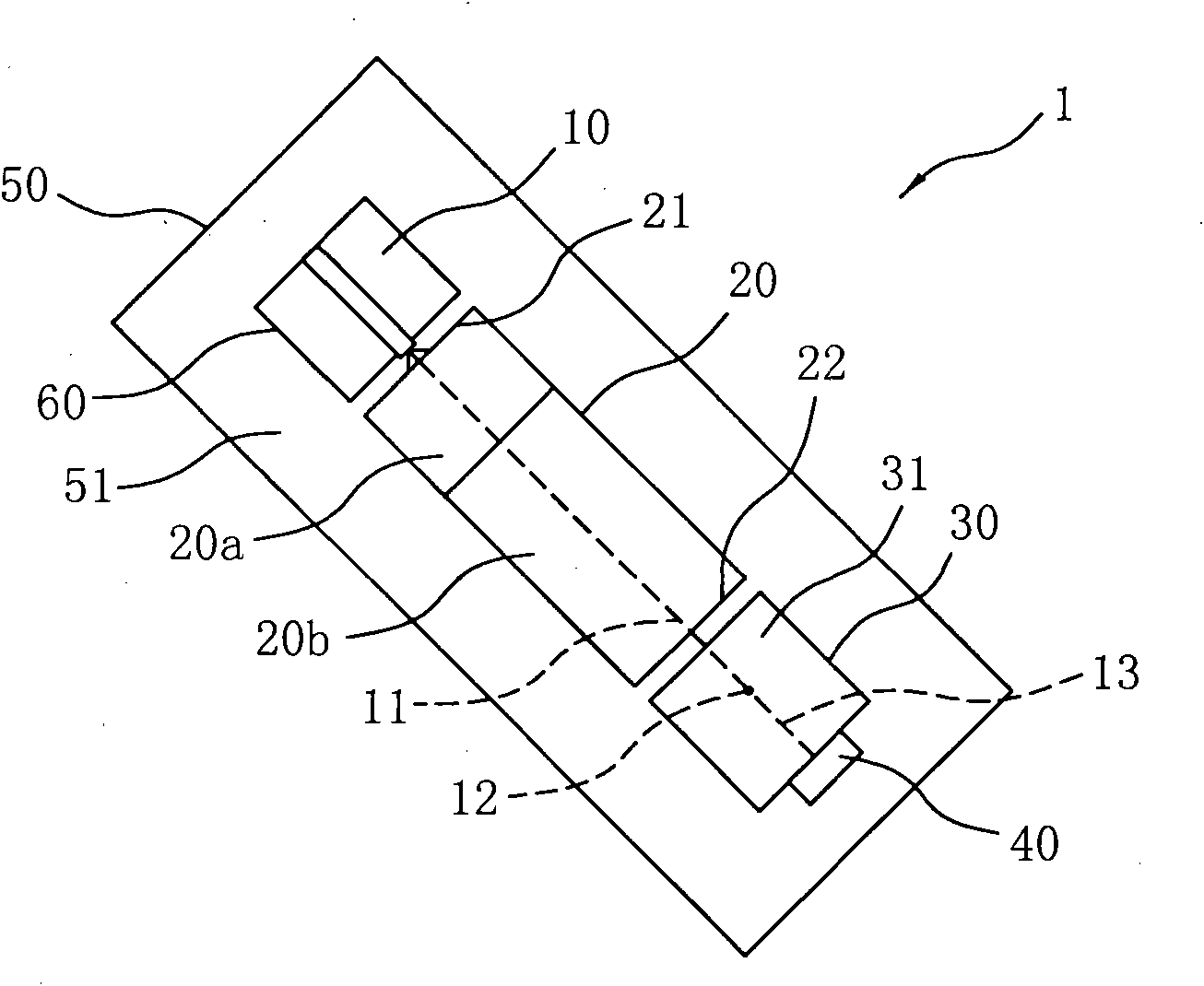

[0037] refer to figure 1 , 2 As shown, they are respectively a schematic diagram of the basic structure (which can be regarded as the first embodiment) of the miniature solid-state laser module of the present invention and a schematic top view thereof. The miniature solid-state laser module 1 of this embodiment adopts the mode of direct optical coupling, that is, this embodiment uses an 808 laser diode chip (808LD chip) to emit laser light with a wavelength of 808nm, and within a very short distance of about 2-3um, the incident In the nonlinear crystal 20a and the frequency doubling crystal 20b of the wavelength converter 20, it is emitted from the output end 22 of the wavelength converter 20 (frequency doubling crystal 20b), and passes through the spectroscopic device 30 with a 45-degree spectroscopic surface 31, so that the The first light beam 12 can be emitted in a direction 90 degrees from the original incident angle, that is, perpendicular to the installation plane 51 a...

no. 2 example

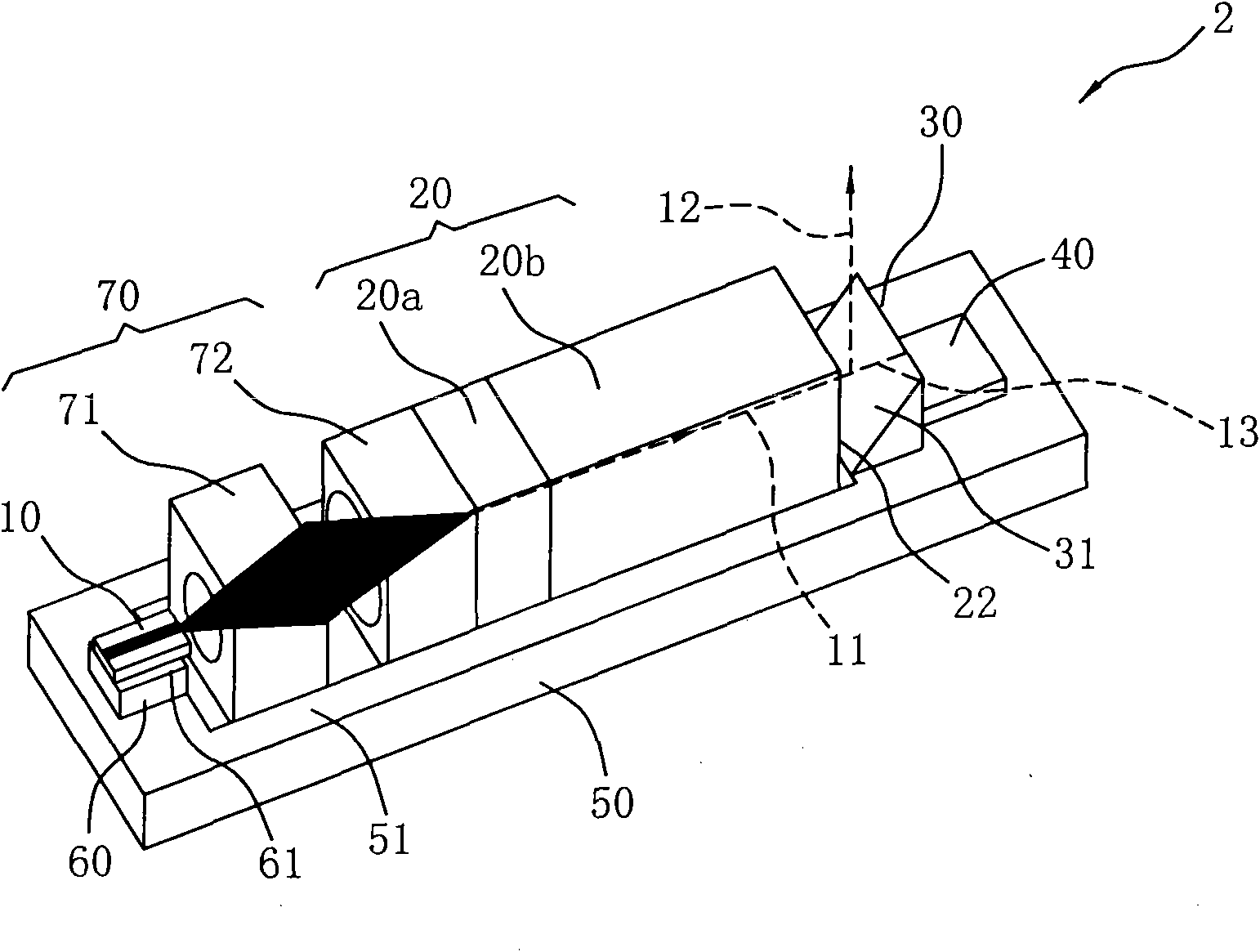

[0039] refer to image 3 As shown, it is a perspective view of the second embodiment of the micro solid-state laser module of the present invention. The miniature solid-state laser module 2 of this embodiment further adopts an indirect optical coupling method to replace the direct optical coupling method of the first embodiment, that is, an additional micro-optical element (Micro Optics) 70 is used to complete the indirect optical coupling requirement, The micro optics element (Micro Optics) 70 can be an optical coupling lens (coupling lens) (not shown), or as image 3 As shown, a collimator lens (collimator lens) 71 and a focusing lens (focusing lens) 72 are combined to form (that is, collimator lens + focusing lens), which not only greatly increases the tolerance of assembly positioning accuracy, but also facilitates Mass production, and the attenuation of light energy is also quite small (less than 2%), which will not affect the power of the light-transmitting laser.

no. 3 example

[0041] refer to Figure 4 , 5 , 6, which are respectively a reference diagram of the internal dimensions of a TO-Can packaging structure and two different schematic top views of the third embodiment of the micro solid-state laser module of the present invention. Due to the limited space for accommodating components in a TO-Can package structure, such as TO-5 Figure 4 As shown, the area of its internal components that can be accommodated is about 5mm × 5mm, so if the solid-state laser 10 of the miniature solid-state laser module of the present invention and its base (Sub-mount) 60, wavelength converter are to be placed in such a limited area 20 such as nonlinear crystal 20a and frequency doubling crystal 20b (such as Nd:YAG and KTP), and other micro optics components (Micro Optics) 70 such as image 3 The shown collimator lens (collimator lens) 71 , focusing lens (focusing lens) and spectroscopic device 30 such as a prism and photodetector 40 and other components may have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com