Dye-sensitized photoelectric conversion device module, method for manufacturing the same, and electronic device

A technology of photoelectric conversion elements and dyes, which can be used in electrical components, photovoltaic power generation, battery electrodes, etc., and can solve the problems of low photoelectric conversion efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

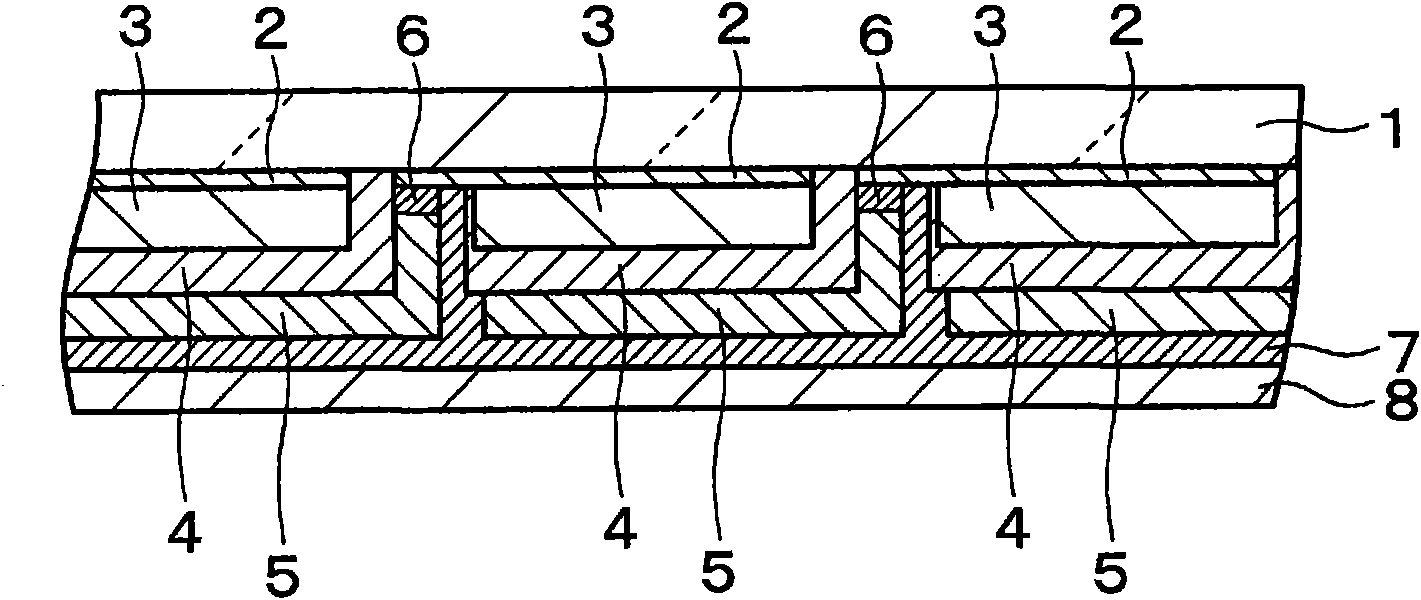

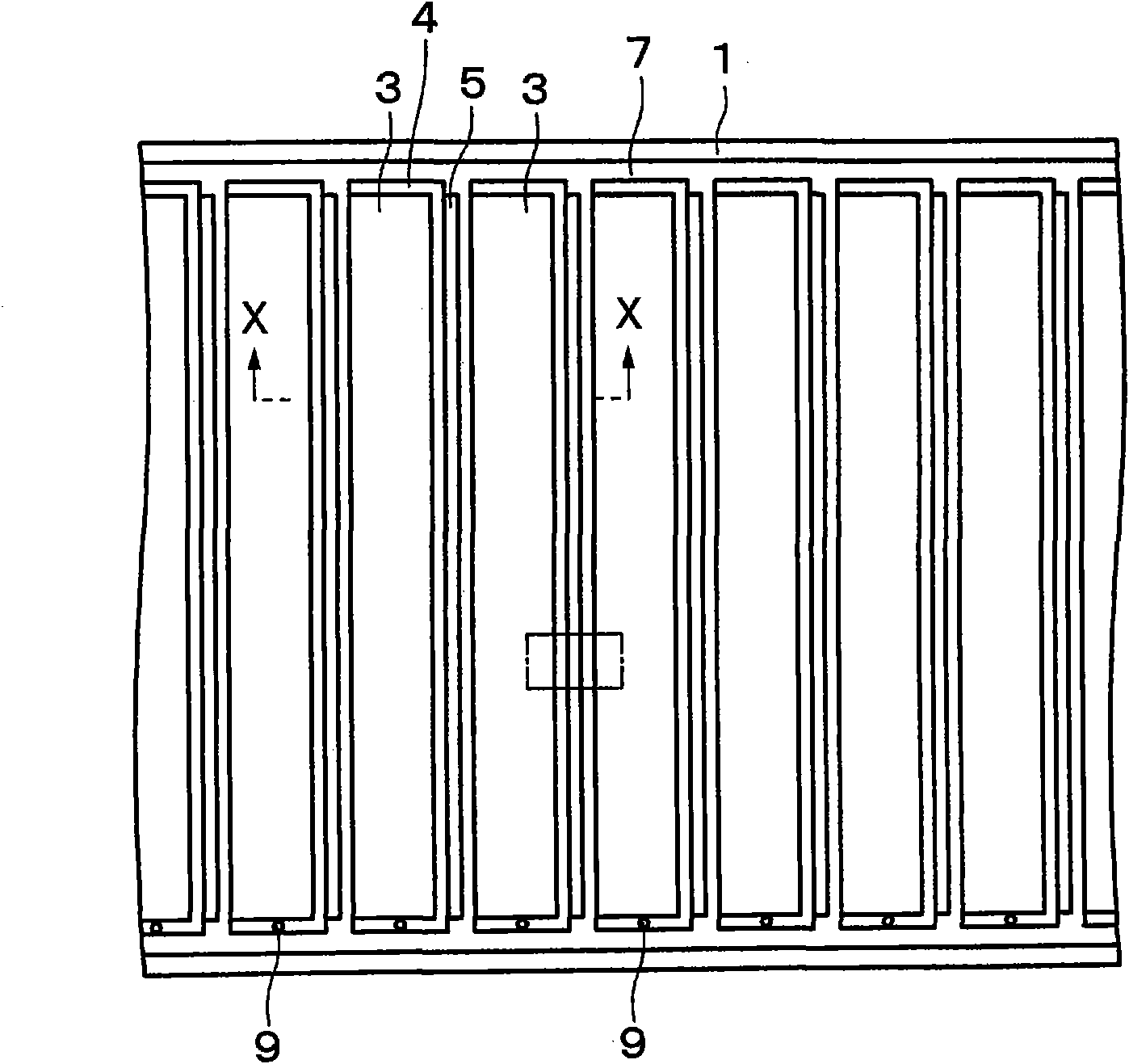

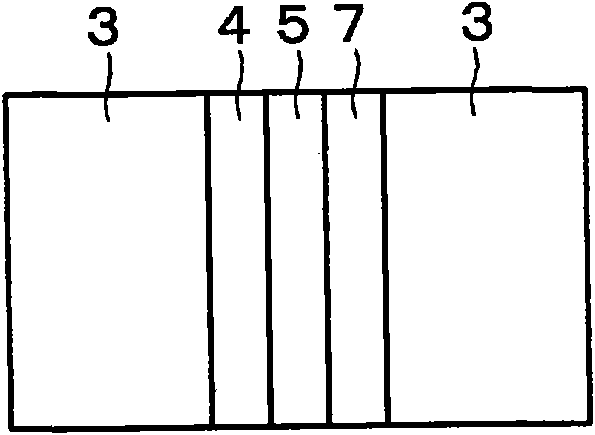

[0064] After the FTO film was formed on the glass substrate, the FTO film was patterned into 8 stripe patterns by etching such that a gap with a width of 0.5 mm was defined between every 2 stripe patterns. Thereafter, ultrasonic cleaning is performed using acetone, alcohol, an alkaline cleaning solution, and ultrapure water in this order, and drying is sufficiently performed.

[0065] Titanium oxide paste made of Solaronix was applied onto a glass substrate by using a screen printing machine so as to obtain 8 stripe patterns each having a width of 5 mm and a length of 40 mm (a total area of 16 cm 2 ). Regarding the paste, a transparent Ti-Nanoxide TSP paste and a Ti-Nanoxide DSP containing scattering particles therein were sequentially laminated from the glass substrate side so as to have a thickness of 7 μm and a thickness of 13 μm, respectively. As a result, porous TiO with a total thickness of 20 μm was obtained 2 membrane. Firing porous TiO in an electric furnace at 5...

Embodiment 2

[0075] A dye-sensitized photoelectric conversion element module was manufactured similarly to the case of Example 1 except that the carbon paste for the counter electrode was formed into a foil shape.

Embodiment 3

[0077] A dye-sensitized photoelectric conversion element module was fabricated similarly to the case of Example 1 except that the counter electrode was formed into a foil shape with platinum-supported carbon paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com