Method for preparing metallic magnesium by carbothermic reduction and device thereof

A metal magnesium and carbothermal technology, applied in the field of carbothermal reduction to prepare metal magnesium, can solve the problems of high energy consumption and high cost, and achieve the effects of eliminating environmental pollution, easy preparation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

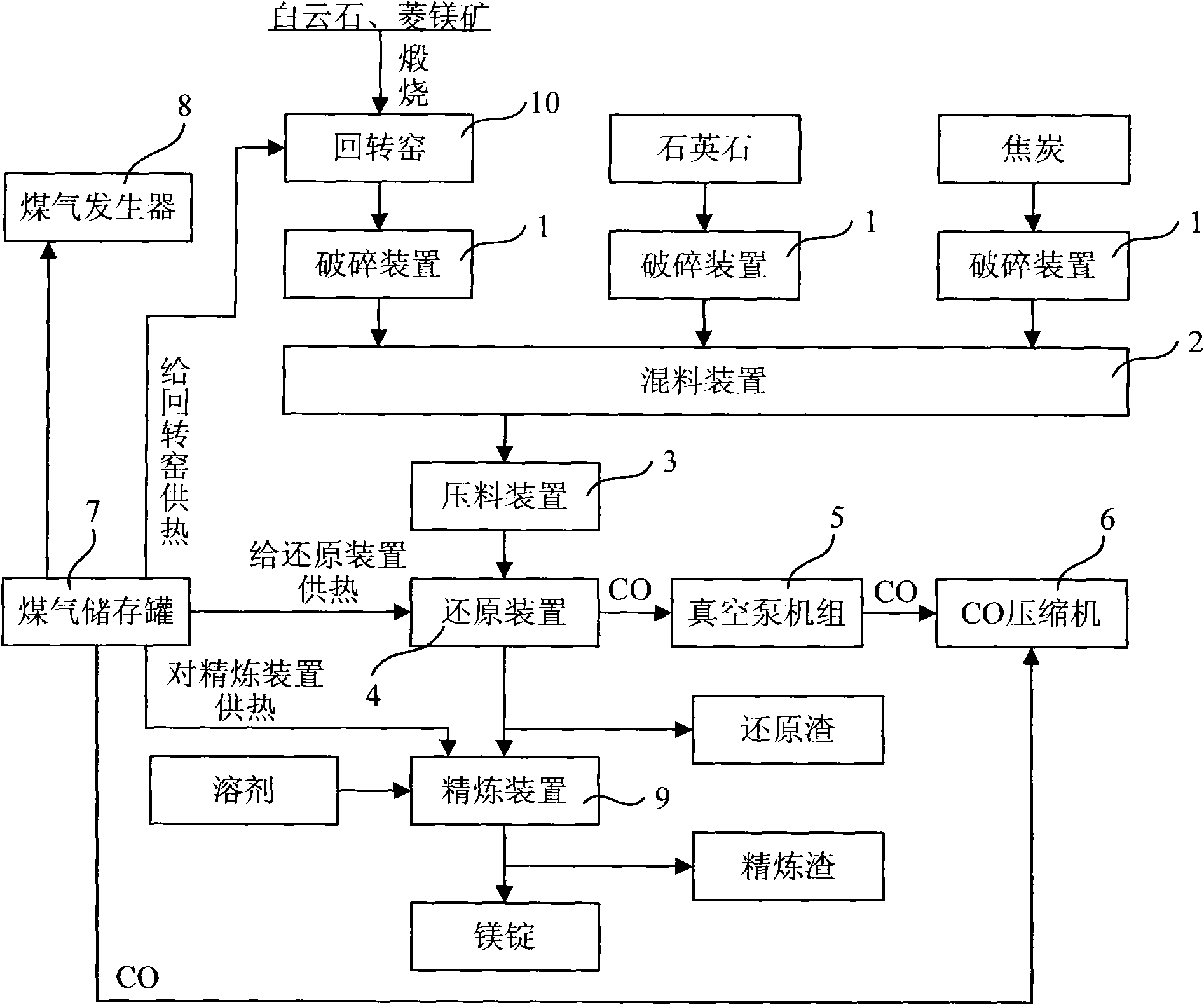

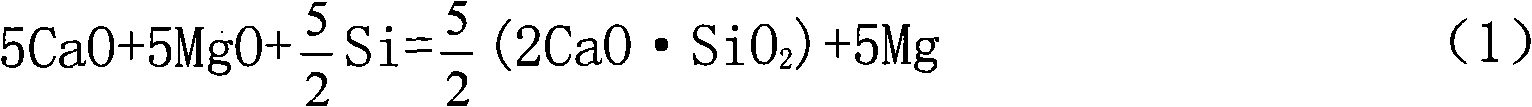

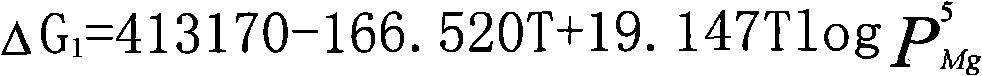

[0164] The calcined dolomite 134.62kg, quartz stone 35.05kg and coke 17.66kg are crushed by the crushing device 1 to make the particle size between 100-200 mesh, preferably 150 mesh, and the crushed materials are mixed in the mixing device 2. Then, the mixture is compressed in the pressing device 3 to become a block, and the compressed mixture is transported to the reduction device 4 (Φ339, 3.25 meters long, 200-210kg) The reduction reaction is carried out, wherein the reduction reaction temperature is 1200° C., the vacuum degree is 10 Pa, and the reduction time is 12 hours. The crude magnesium produced by the reduction reaction is refined and cast to form a magnesium ingot, and the purity of the product is 99.90%. In addition, the carbon monoxide gas produced by the reduction reaction is extracted by the vacuum pump unit 5 and sent to the carbon monoxide compressor 6. After that, the compressed carbon monoxide gas is fed into the coal gas storage tank 7 and heats the reduction ...

Embodiment 2

[0166] 81.93kg of calcined dolomite, 20.86kg of calcined magnesite, 26.83kg of quartz stone and 15.43kg of coke are crushed by crushing device 1, so that the particle size is between 100-200 mesh, preferably 150 mesh. Mixing is carried out in the mixing device 2, and then the mixture is compressed in the pressing device 3 to become a block, and the compressed mixture is transported to the reduction device 4 (Φ325, 2.9 meters long, The charge amount is 145.05kg) for the reduction reaction, where the reduction reaction temperature is 1200°C, the vacuum degree is 10 Pa, and the reduction time is 12 hours. The crude magnesium produced by the reduction reaction is refined and cast to form magnesium ingots. The purity of the product is 99.90%. In addition, the carbon monoxide gas produced by the reduction reaction is extracted by the vacuum pump unit 5 and sent to the carbon monoxide compressor 6. After that, the compressed carbon monoxide gas is fed into the coal gas storage tank 7 ...

Embodiment 3

[0168] The calcined dolomite 112.96kg, the calcined magnesite 28.67kg, the quartz stone 21.38kg and the coke 21.38kg are crushed by the crushing device 1, so that the particle size is between 100-200 mesh, preferably 150 mesh. Mixing is carried out in the mixing device 2, and then the mixture is compressed in the pressing device 3 to become a block, and the compressed mixture is transported to the reduction device 4 (Φ339, 3.25 meters long, The charging amount is 200~210kg) to carry out the reduction reaction. The temperature of the reduction reaction is 1225℃, the vacuum degree is 10Pa, and the reduction time is 14 hours. The crude magnesium produced by the reduction reaction is refined and cast to form magnesium ingots. The purity of the product Is 99.90%. In addition, the carbon monoxide gas produced by the reduction reaction is extracted by the vacuum pump unit 5 and sent to the carbon monoxide compressor 6. After that, the compressed carbon monoxide gas is fed into the coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com