Bio-fertilizer produced by fermenting industrial organic wastes residue and waste mother solution

A technology of organic waste slag and biological fertilizer, applied in the direction of organic fertilizer, organic fertilizer preparation, fertilizer made of biological waste, etc., can solve the problem of no utilization, etc., achieve simple method, good economic and environmental benefits, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in more detail below by specific embodiment:

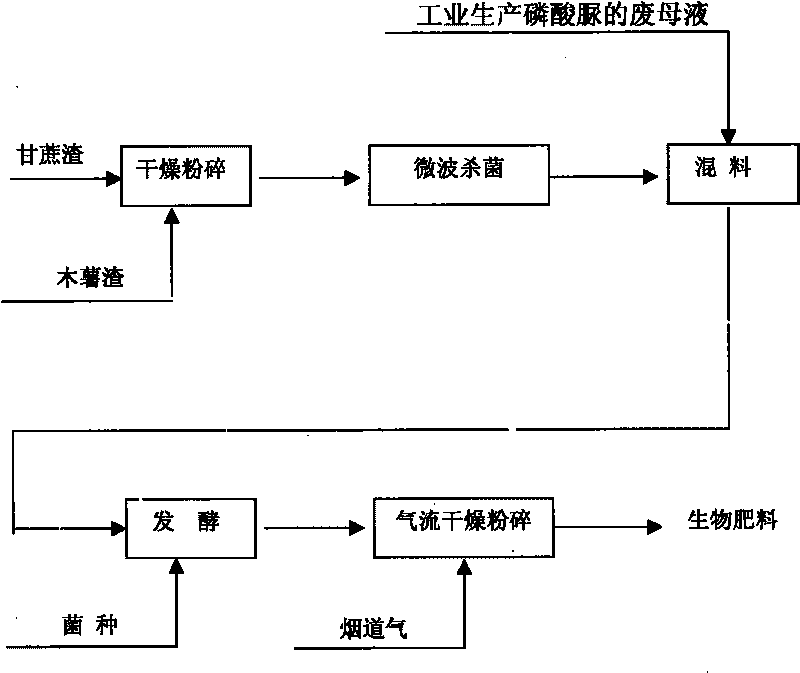

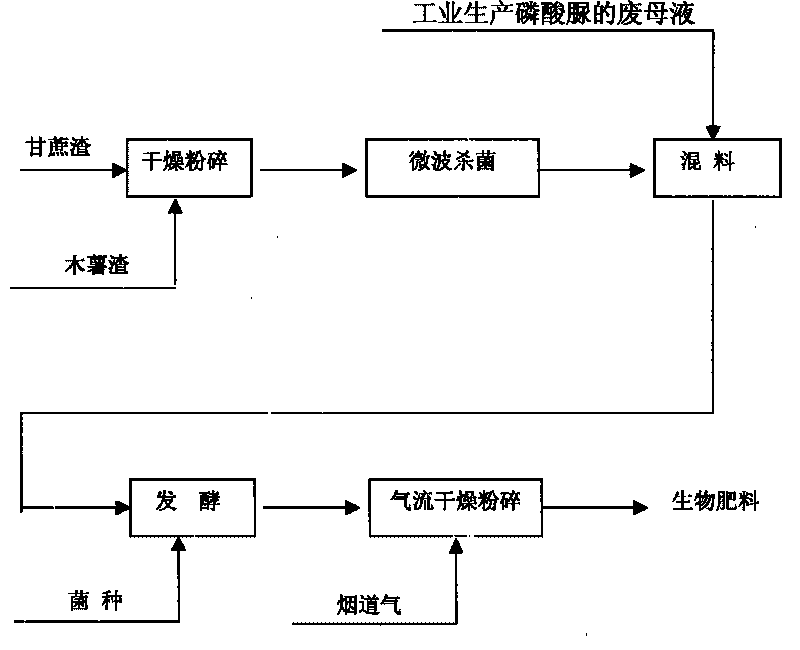

[0013] refer to figure 1 , with the bagasse of the sugar factory and the cassava bagasse of the monosodium glutamate factory, the water content of the two kinds of bagasses is all at 11% (percentage by weight, the same below), and then the two kinds of bagasses are pulverized into 25% with the blade crusher. The weight ratio of bagasse and cassava bagasse is: bagasse: cassava bagasse=3: 1, after the two are mixed, send into the microwave oven for sterilization for 2 minutes, then use the container with stirring, under normal temperature and pressure, start the agitator Complete the following operations: add the waste mother liquor in the industrial production of urea phosphate, the waste mother liquor contains H 3 PO 4 CO(NH 2 ) 2 = 3%, the addition amount is 3% of the mixed slag, then, add 5% of Trichoderma seed liquid, 6% of brown spherical nitrogen-fixing bacteria liquid, 4% of Baci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com