Transition metal catalyst and method for preparing picoline through adopting catalyst

A transition metal and catalyst technology, applied in the field of preparing methyl pyridine, can solve the problems of high reaction temperature, low yield, difficult product separation, etc., and achieve the effects of good production safety and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

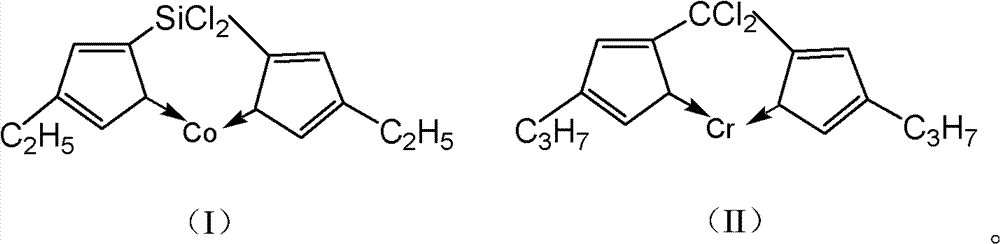

Image

Examples

Embodiment 1

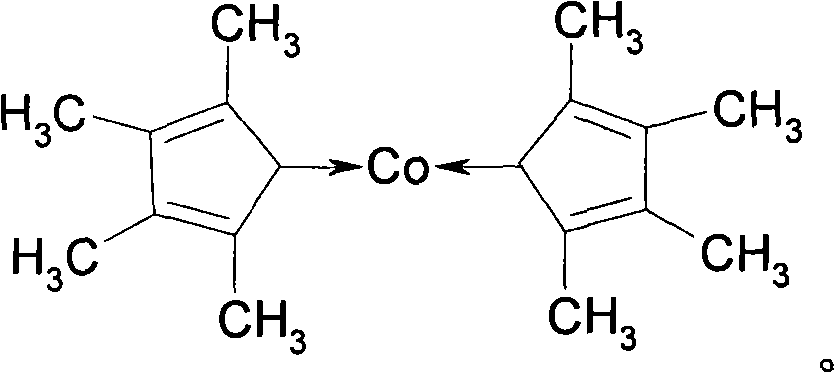

[0018] This example is used to illustrate the transition metal catalyst provided by the present invention.

[0019] At room temperature, in a nitrogen atmosphere, mix 2 moles of sodium tetramethylcyclopentadienyl and 1.2 moles of anhydrous CoCl 2 Add 300 ml of tetrahydrofuran for contact reaction for 2 hours, vacuum filter the mixture obtained after the reaction (absolute pressure is 0.01MPa), and then crystallize by evaporation to obtain purple-black crystals, which are analyzed by nuclear magnetic resonance and mass spectrometry. It is known that the crystal is the transition metal catalyst A1 shown in structural formula 1,

[0020] Structural formula 1

[0021]

Embodiment 2

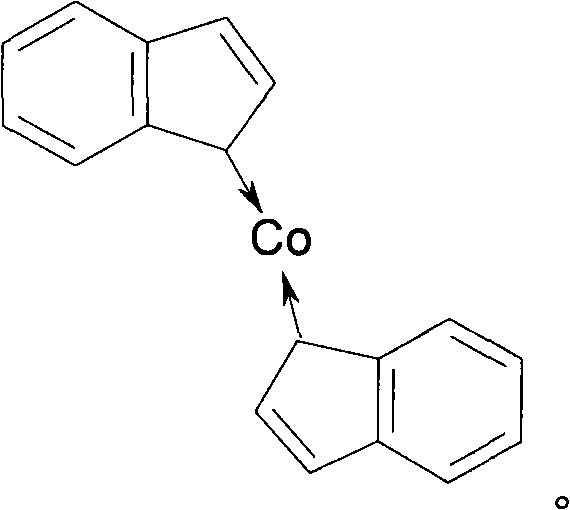

[0023] This example is used to illustrate the transition metal catalyst provided by the present invention.

[0024] At room temperature, in a nitrogen atmosphere, mix 2 moles of indenyl sodium and 1.2 moles of anhydrous CoCl 2 Add 200 ml of tetrahydrofuran for contact reaction for 2.5 hours, vacuum filter the mixture obtained after the reaction (absolute pressure, that is, the vacuum degree is 0.01MPa), and then crystallize by evaporation to obtain purple-black crystals, and analyze by nuclear magnetic resonance and mass spectrometry. Knowing that the crystal is the transition metal catalyst A2 shown in structural formula 2,

[0025] Structural formula 2

[0026]

Embodiment 3

[0028] This example is used to illustrate the transition metal catalyst provided by the present invention.

[0029] At room temperature, in a nitrogen atmosphere, mix 2 moles of sodium fluorenyl and 1.3 moles of anhydrous CoCl 2 Add 400 ml of tetrahydrofuran for contact reaction for 2.5 hours, vacuum filter the mixture obtained after the reaction (absolute pressure, that is, the vacuum degree is 0.01MPa), and then crystallize by evaporation to obtain purple-black crystals, analyzed by nuclear magnetic resonance and mass spectrometry It is known that the crystal is the transition metal catalyst A3 represented by structural formula 3.

[0030] Structural formula 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com