Method for treating waste water with high pH value, high sulfide content, high ammonia nitrogen content and high COD content

A treatment method and sulfide technology, which is applied in the field of high ammonia nitrogen, high sulfide, "high pH, high COD" wastewater treatment, can solve the problems of biochemical system failure to start normally, poor flocculation and sedimentation effect, and effluent water quality exceeding the standard, etc. Achieve the effects of good indicators, improve settlement performance, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

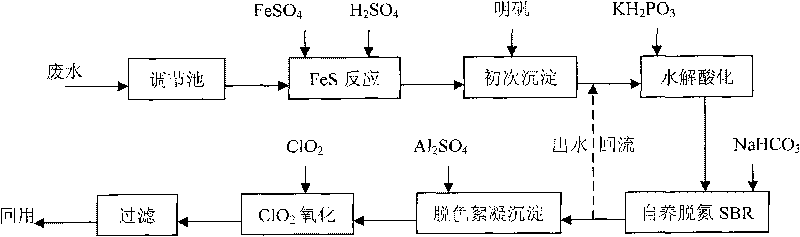

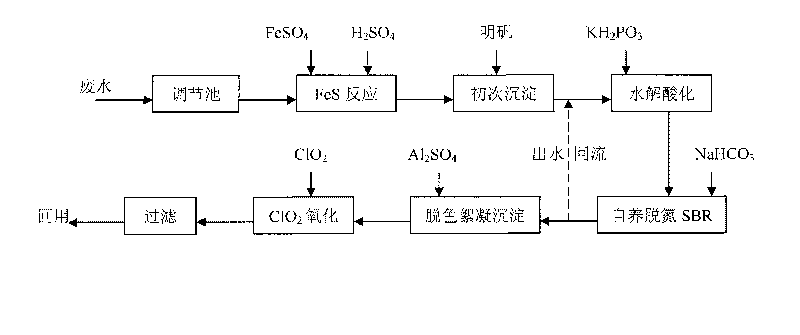

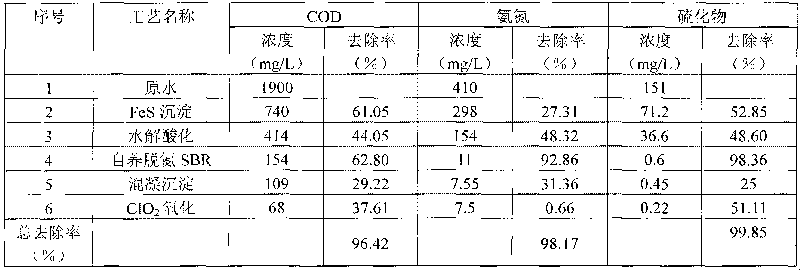

[0028] After the wastewater from each mineral processing chemical workshop is collected and adjusted to be homogenized, it forms the comprehensive wastewater of the mineral processing chemical plant. The waste water is pretreated first, and the pretreatment adopts the acidification-ferrous salt precipitation method, and the amount of ferrous salt is 0.7kg / m 3 , sulfuric acid 2.21kg / m 3 , alum 0.3kg / m 3 . The ferrous salt precipitation section can remove the S in the wastewater 2- The COD caused by the acidification process also decomposes the organic matter hydrolyzed by acidification in the wastewater to remove part of the COD. The pretreatment COD removal rate is about 61.05%, the sulfide removal rate is 52.85%, and the ammonia nitrogen removal rate is 27.31%.

[0029] After the pretreatment wastewater is precipitated, carry out the biological treatment process. The biological treatment process adopts the hydrolytic acidification-autotrophic SBR process. The hydraulic ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com