Compound soft magnetic material with operational performances of high-frequency and large power and process for preparing same

A technology of composite soft magnetic and soft magnetic composite materials, which is applied in the field of soft magnetic materials and its preparation, can solve the problems of unsuitable use of Somaloy series, low insulation performance of the cladding layer, complicated cladding process, etc., and achieve environmental friendliness Effects of industrial production, suitable for industrial production, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

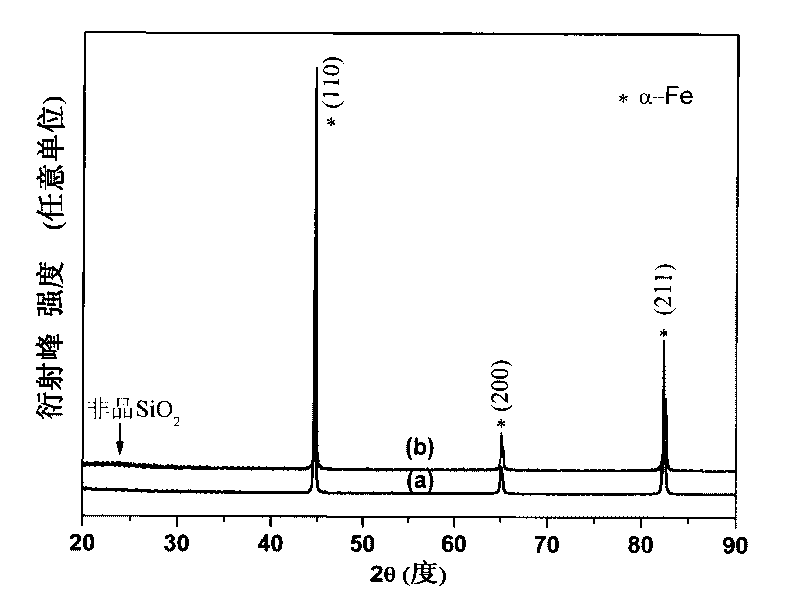

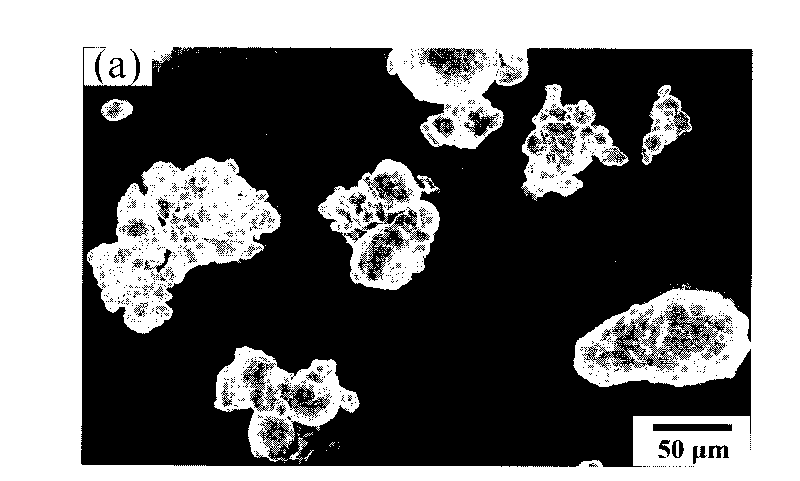

[0035] Composite soft magnetic material with high frequency and high power use characteristics, its composition is Fe / SiO 2 Core-shell composite structure, in which the particle size of iron powder is 107μm, SiO 2 Uniformly coated on the surface of iron powder particles, SiO 2 The thickness of the cladding layer is 200nm, SiO2 The mass fraction of Fe is 4.97%, and the mass fraction of Fe is 95.03%.

[0036] A method for preparing a composite soft magnetic material with high-frequency and high-power usage characteristics, comprising the following steps:

[0037] 1. Take 50 g of commercially available high-purity iron powder with a particle size of 107 μm and a mass fraction of Fe element greater than 99.8%, and wash it twice with analytically pure acetone and analytically pure ethanol;

[0038] 2. Put the cleaned iron powder into a container containing analytical pure ethanol, 25% ammonia and analytical pure oleic acid and stir to form the iron powder mixture. The mass ratio ...

Embodiment 2

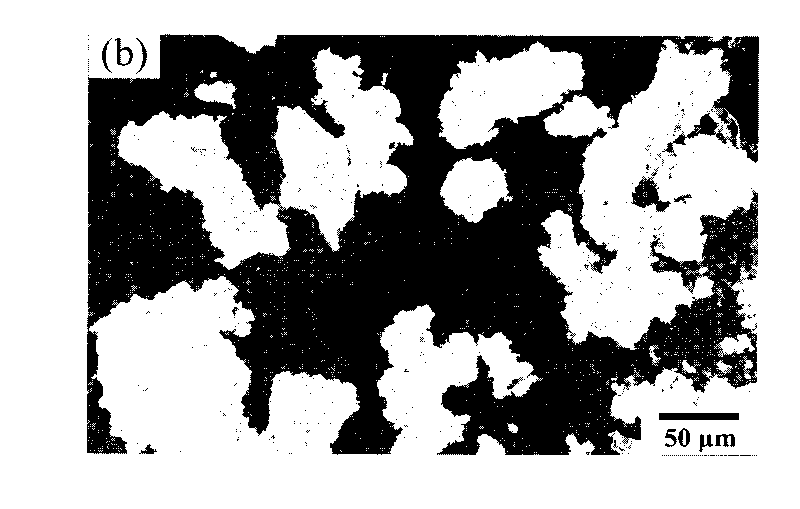

[0049] Composite soft magnetic material with high frequency and high power use characteristics, its composition is Fe / SiO 2 Core-shell composite structure, in which the particle size of iron powder is 121μm, SiO 2 Uniformly coated on the surface of iron powder particles, SiO 2 The thickness of the cladding layer is 152nm, SiO 2 The mass fraction of Fe is 2.71%, and the mass fraction of Fe is 97.29%.

[0050] A method for preparing a composite soft magnetic material with high-frequency and high-power usage characteristics, comprising the following steps:

[0051] 1. Take 50 g of commercially available high-purity iron powder with a particle size of 121 μm and a mass fraction of Fe element greater than 99.8%, and wash it once with analytically pure acetone and analytically pure ethanol;

[0052] 2. Put the cleaned iron powder into a container containing analytical pure ethanol, 25% ammonia and analytical pure oleic acid and stir to form the iron powder mixture. The mass ratio...

Embodiment 3

[0059] Composite soft magnetic material with high frequency and high power use characteristics, its composition is Fe / SiO 2 Core-shell composite structure, in which the particle size of iron powder is 38μm, SiO 2 Uniformly coated on the surface of iron powder particles, SiO 2 The thickness of the cladding layer is 300nm, SiO 2 The mass fraction of Fe is 10.12%, and the mass fraction of Fe is 89.88%.

[0060] A method for preparing a composite soft magnetic material with high-frequency and high-power usage characteristics, comprising the following steps:

[0061] 1. Take 50 g of commercially available high-purity iron powder with a particle size of 38 μm and a mass fraction of Fe element greater than 99.8%, and wash it twice with analytically pure acetone and analytically pure ethanol;

[0062] 2. Put the cleaned iron powder into a container containing analytical pure ethanol, 25% ammonia and analytical pure oleic acid and stir to form the iron powder mixture. The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com