Glass fiber with low dielectric constant for high frequency high-density circuit board

A low-dielectric constant, glass fiber technology, used in the reinforcement material of high-frequency high-density multi-layer interconnection printed circuit boards, in the field of low-dielectric constant glass fiber, can solve the problem that the adhesion of glass fiber water-resistant resin is not ideal , The dielectric properties are not ideal, the moisture resistance is not ideal, etc., to achieve the effect of easy subsequent processing, good resin adhesion, and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

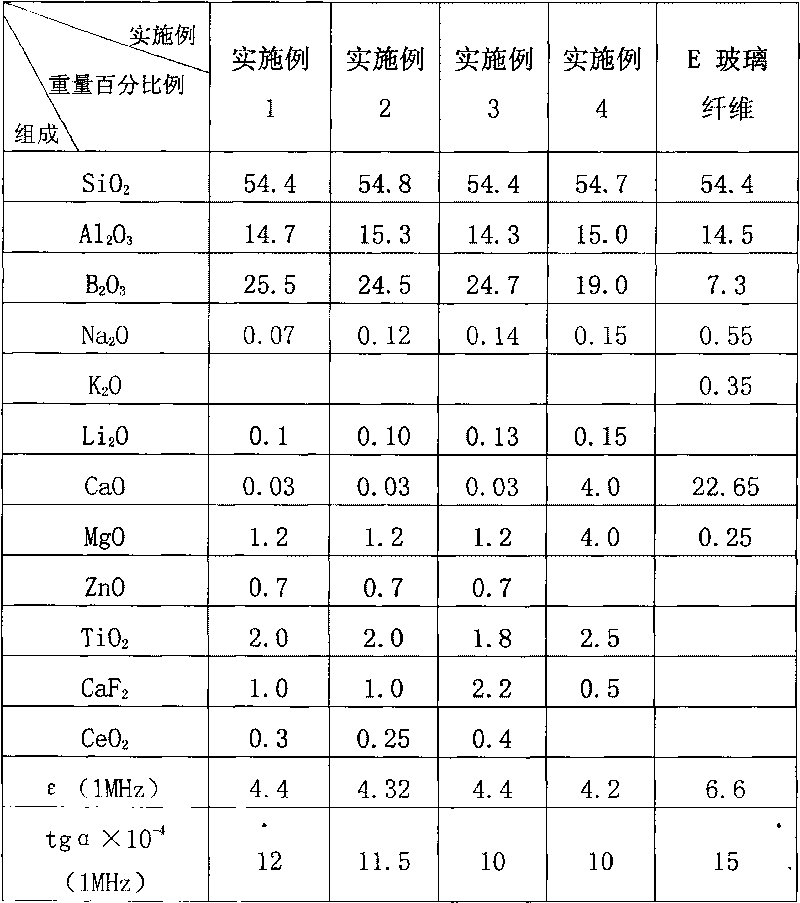

[0027] A low-dielectric-constant glass fiber used for high-frequency and high-density circuit boards. The composition and weight percentage of each component are shown in Table 1 below:

[0028] The preparation method of the glass fiber of each example in Table 1 is: take the components according to the composition and weight percentage in Table 1, mix the materials and stir them evenly into the furnace, heat to 1540°C, and clarify at 1520°C After 8 hours, after melting, the ball is made into a glass ball, and the ball is placed in a platinum tongs pot and heated to 1560°C. The molten glass solution flows out through the platinum drain plate, and is infiltrated by the sizing agent and drawn into glass by the wire drawing machine. Fiber, used to prepare glass fiber cloth. To test the dielectric properties, the molten glass is processed into a flat sample, and the dielectric constant and the dielectric loss factor of the glass block at 1MHz are measured.

[0029] Table 1:

[0030]

...

Embodiment 5-16

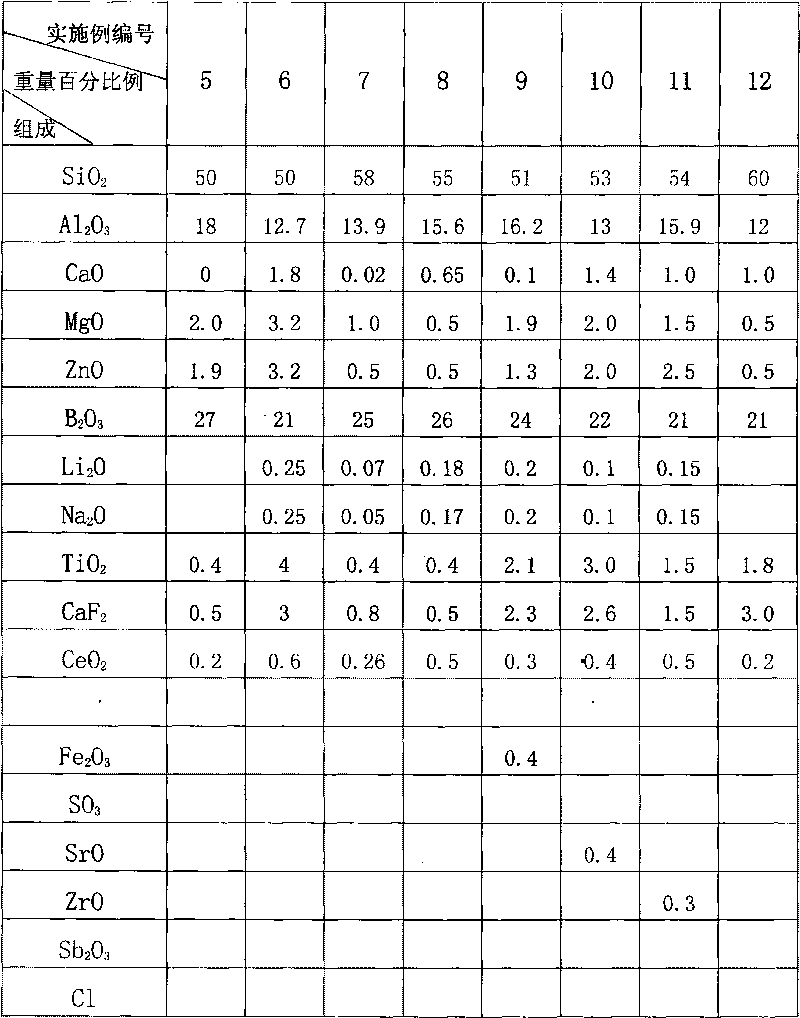

[0034] A low-dielectric-constant glass fiber used for high-frequency and high-density circuit boards. The composition and weight percentage of each component are shown in Table 2 below:

[0035] Table 2:

[0036]

[0037] The preparation method of the glass fiber of each example in Table 2 is: take the components according to the composition and weight percentage in Table 2, mix the materials and stir them evenly into the kiln, heat to 1400~1700°C, and heat it at 1500~ Clarified at 1550°C for 8 hours. After melting, the ball is made into a glass ball. The ball is placed in a platinum clamp pot and heated to 1550~1600°C. The molten glass solution flows out through the platinum drain plate, and is infiltrated by the infiltration agent. The wire drawing machine becomes glass fiber after wire drawing. To test the dielectric properties, the molten glass is processed into a flat sample, and the dielectric constant and the dielectric loss factor of the glass block at 1 MHz are measured. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com