Method for synthesizing quantum dot with uniform size distribution in aqueous phase

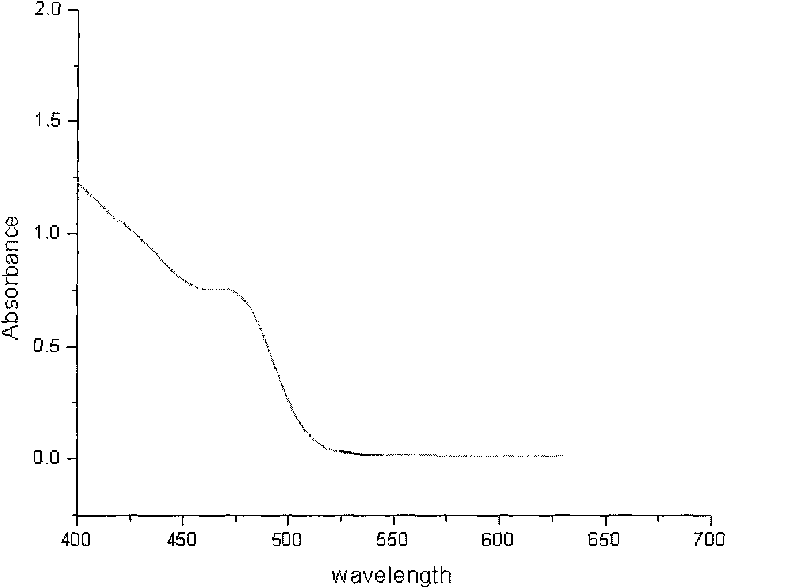

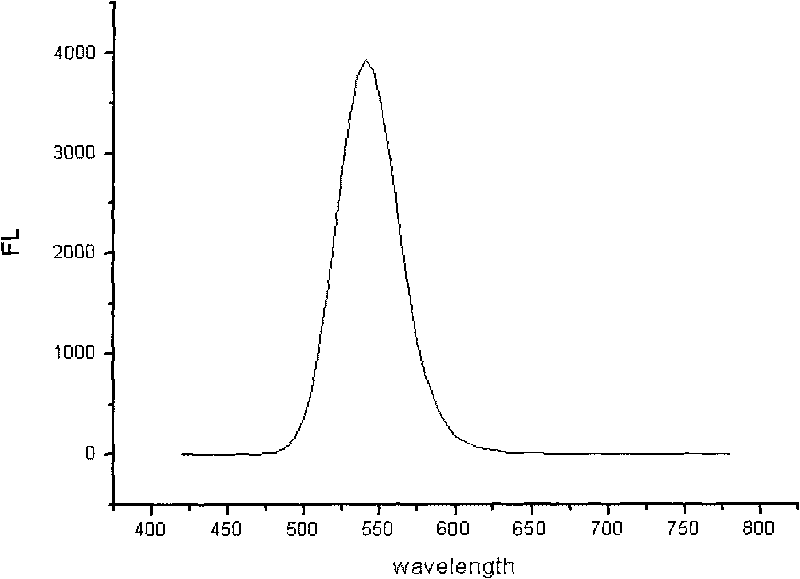

A technology of particle size distribution and quantum dots, which is applied in chemical instruments and methods, binary selenium/tellurium compounds, luminescent materials, etc., can solve the problem of uneven particle size distribution of quantum dots, poor water solubility of quantum dots, and difficulty in application, etc. problem, to achieve the effect of low toxicity, good biophilicity and good monochromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step is to prepare template agent

[0027] Prepare P123 tri-block polymer mother solution. Weigh 0.14 g of a P123 tri-block polymer with a molecular weight of 8400 in a beaker. Then add 200 mL of deionized water; stir for 120 minutes until a uniform colorless and transparent solution is formed; take out 2 mL and dilute to 180 mL.

[0028] The second step is to prepare the precursor of cadmium-mercapto complex

[0029] Weigh 0.0228g CdCl 2 2.5H 2 O was dissolved in 10mL deionized water to form a colorless and transparent solution, which was added dropwise to the solution prepared in the first step, and stirred for 2 hours, the solution was still colorless and transparent; Acetic acid (TGA) 1.4×10 -2 mL, a white insoluble matter will be produced immediately. After fully stirring, adjust the pH value of the solution to 8 with 10 mL of 1 mol / L NaOH solution to form a colorless, transparent and clear solution.

[0030] The third step is to prepare the S sourc...

Embodiment 2

[0035] The first step is to prepare template agent

[0036] Prepare polyethylene glycol stock solution. Weigh 0.122 g of polyethylene glycol with a molecular weight of 5000 in a beaker. Then add 200 mL of deionized water; stir for 120 minutes until a uniform colorless and transparent solution is formed; take out 2 mL and dilute to 180 mL.

[0037] The second step is to prepare the precursor of cadmium-mercapto complex

[0038] Weigh 0.0336g CdCl 2 2.5H 2 O was dissolved in 10 mL of deionized water to form a colorless and transparent solution. Add this solution dropwise to the solution prepared in the first step, and stir for 2 hours; the solution is still colorless and transparent; slowly add thioglycolic acid (TGA) 1.9×10 -2 mL, a white insoluble matter will be produced immediately. After fully stirring, use 12 mL of 1 mol / L NaOH solution to adjust the pH value of the solution to 8.5 to form a colorless, transparent and clear solution.

[0039] The third step is to prep...

Embodiment 3

[0044] The first step is to prepare template agent

[0045] Weigh 4.54×10 -5 g of sodium dodecylsulfonate (SDS) was dissolved in a small amount of deionized water and diluted to 180 mL.

[0046] The second step is to prepare the precursor of cadmium-mercapto complex

[0047] Weigh 0.0230g Cd(Ac) 2Dissolve in 10mL deionized water to form a colorless and transparent solution, add the solution dropwise to the solution prepared in the first step, stir for 1.5 hours, the solution is still colorless and transparent; add reduced glutathione to the solution 0.3073g, white insoluble matter is produced immediately, after fully stirring, use 1mol / L NaOH solution 18mL to adjust the pH value of the solution to 9, forming a colorless transparent clear solution.

[0048] The third step is to prepare the Se source precursor

[0049] In a small beaker add 9.0792×10 -3 g NaBH 4 , 4.7376×10 -3 g Se and 6mL deionized water, and ultrasonically reacted for 2.5 hours under a water seal, the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com