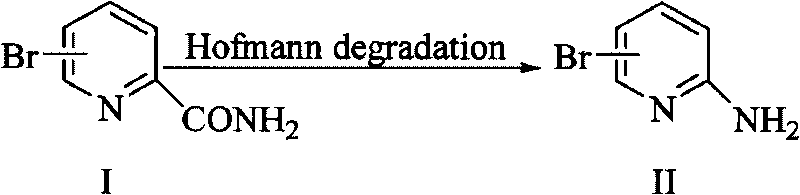

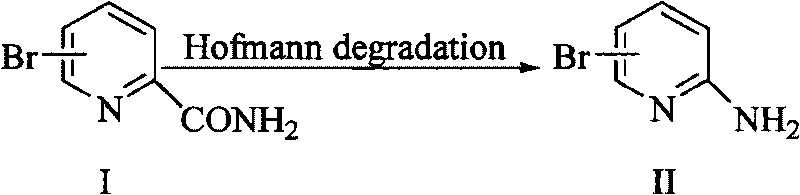

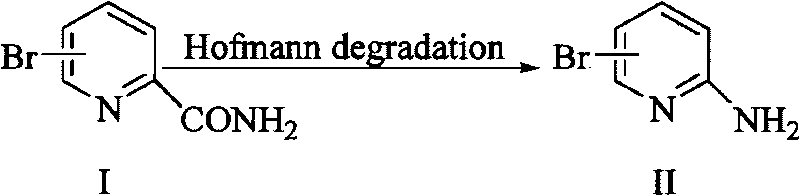

Preparation method of amino pyridine bromide compound

A technology for aminobromopyridine and bromopyridinecarboxamide, which is applied in the field of preparing aminobromopyridine based on Hoffman degradation reaction, can solve the problems of unobtainable raw materials, harsh reaction conditions, long process route, etc., and meets equipment requirements Low, high product purity, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 24g (0.6mol) of sodium hydroxide and 180g (10mol) of water into a four-neck flask equipped with a stirrer, a condenser, and a thermometer, and slowly add 17.6g (0.11mol) of liquid bromine at -5 to 0°C, dropwise After finishing this temperature, the reaction was continued for 1.0 h to obtain fresh sodium hypobromite solution. Add 20.1g (0.1mol) of 6-bromo-2-pyridinecarboxamide in batches to the sodium hypobromite solution until completely dissolved, react at 70°C for 0.5h, cool down to 0°C after the reaction, filter to obtain a white solid Crude. The filtrate was extracted with dichloromethane, the solvent was recovered, cooled and filtered to obtain a white solid crude product. The crude product was recrystallized from petroleum ether and dried to obtain 9.2 g of 2-amino-6-bromopyridine with a yield of 53.2% and a melting point of 88-89°C. The purity was 99.0% by HPLC.

Embodiment 2

[0037] With the technological operation step of embodiment 1, different conditions are:

[0038] 20g (0.5mol) of sodium hydroxide, 216g (12mol) of water, 19.2g (0.12mol) of liquid bromine, 20.1g (0.1mol) of 6-bromo-2-pyridinecarboxamide, the degradation reaction was 60°C for 1.0h, and 2 -Amino-6-bromopyridine 9.4g, yield 54.3%, melting point 88-89°C.

Embodiment 3

[0040] With the technological operation step of embodiment 1, different conditions are:

[0041]20g (0.5mol) of sodium hydroxide, 216g (12mol) of distilled water, 20.1g (0.1mol) of 5-bromo-2-pyridinecarboxamide, degraded at 60°C for 1.0h, and extracted the filtrate with chloroform to obtain a light yellow solid 2-amino -5-bromopyridine 10.6g, yield 61.3%, melting point 135-138°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com