Ultraviolet curing glue for adhering and sealing FPC and plasma screen glass

A technology of adhesive sealing and plasma screen, which is applied in the direction of adhesive, adhesive type, discharge tube/lamp manufacturing, etc., can solve the problems that cannot meet various requirements, and achieve the avoidance of electromigration, high bonding strength, and curing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

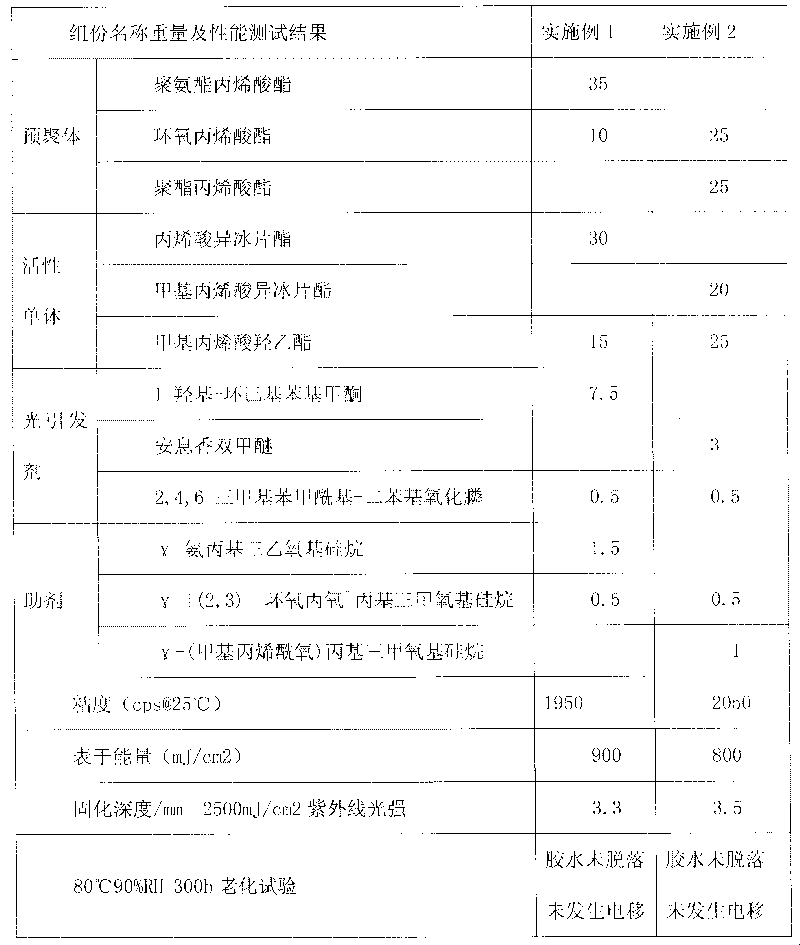

example 1

[0021] Under normal temperature and normal pressure, according to the content of each component specified in the following Table 1, the prepolymer is selected from polyurethane acrylate and epoxy acrylate, and the reactive diluent monomer is selected from isobornyl acrylate and hydroxyethyl methacrylate. The photoinitiator is selected from 1-hydroxy-cyclohexyl phenyl ketone and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and the auxiliary agent is selected from γ-aminopropyl triethoxysilane and γ- [(2,3)-Glycidoxy]propyltrimethoxysilane. Add isobornyl acrylate and hydroxyethyl methacrylate into the reaction vessel, then add 1-hydroxy-cyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, γ-Aminopropyltriethoxysilane and γ-[(2,3)-glycidoxy]propyltrimethoxysilane, stirring at a temperature of 30°C to 60°C, and keeping the temperature at Add urethane acrylate and epoxy acrylate at 30°C to 60°C, and continue stirring to mix evenly.

Embodiment 2

[0023] Under normal temperature and pressure, according to the content of each component specified in Table 1 below, epoxy acrylate and polyester acrylate are used as prepolymers, and isobornyl methacrylate and hydroxymethacrylate are selected as reactive diluent monomers. Ethyl ester, photoinitiator selects benzoin dimethyl ether and 2,4,6-trimethylbenzoyl-diphenyl phosphine oxide, auxiliary agent selects gamma-aminopropyl triethoxysilane and gamma-[(2 , 3)-glycidoxy] propyltrimethoxysilane. Add isobornyl acrylate and hydroxyethyl methacrylate into the reaction vessel, then add 1-hydroxy-cyclohexyl phenyl ketone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, γ-[(2,3)-glycidoxy]propyltrimethoxysilane and γ-(methacryloyloxy)propyltrimethoxysilane, the temperature is controlled to 30 ℃ ~ 60 ℃ and stirred After all dissolve, keep the temperature at 30℃~60℃, add epoxy acrylate and polyester acrylate, continue to stir and mix evenly.

[0024] The UV curing light source is a 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com