Process for smelting ferro-nickel by using nickel oxide minerals and smelting device

A technology of nickel oxide ore and ferronickel, which is applied in the field of technology and smelting equipment, can solve the problems of complex processing technology and high production cost, and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

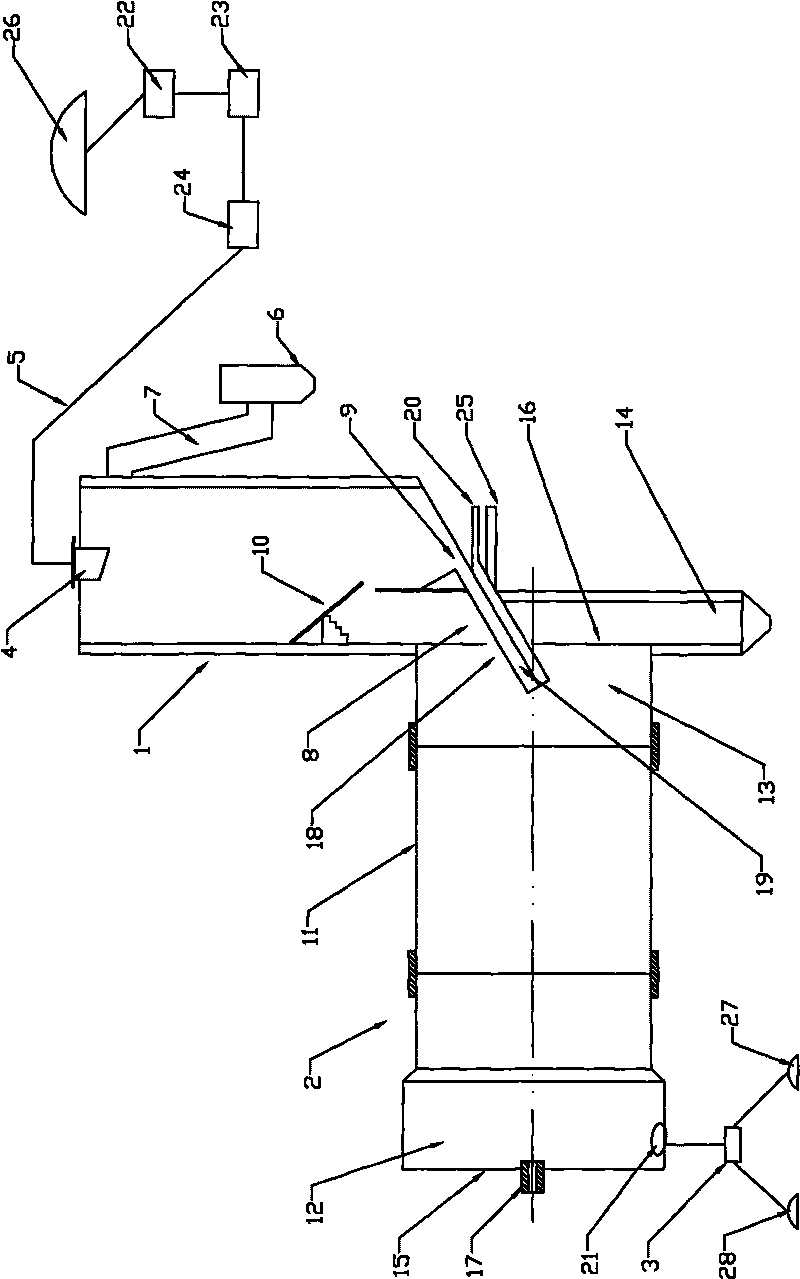

[0030] In order to illustrate the present invention in detail, the present invention will be further described below with specific implementations in conjunction with the accompanying drawings.

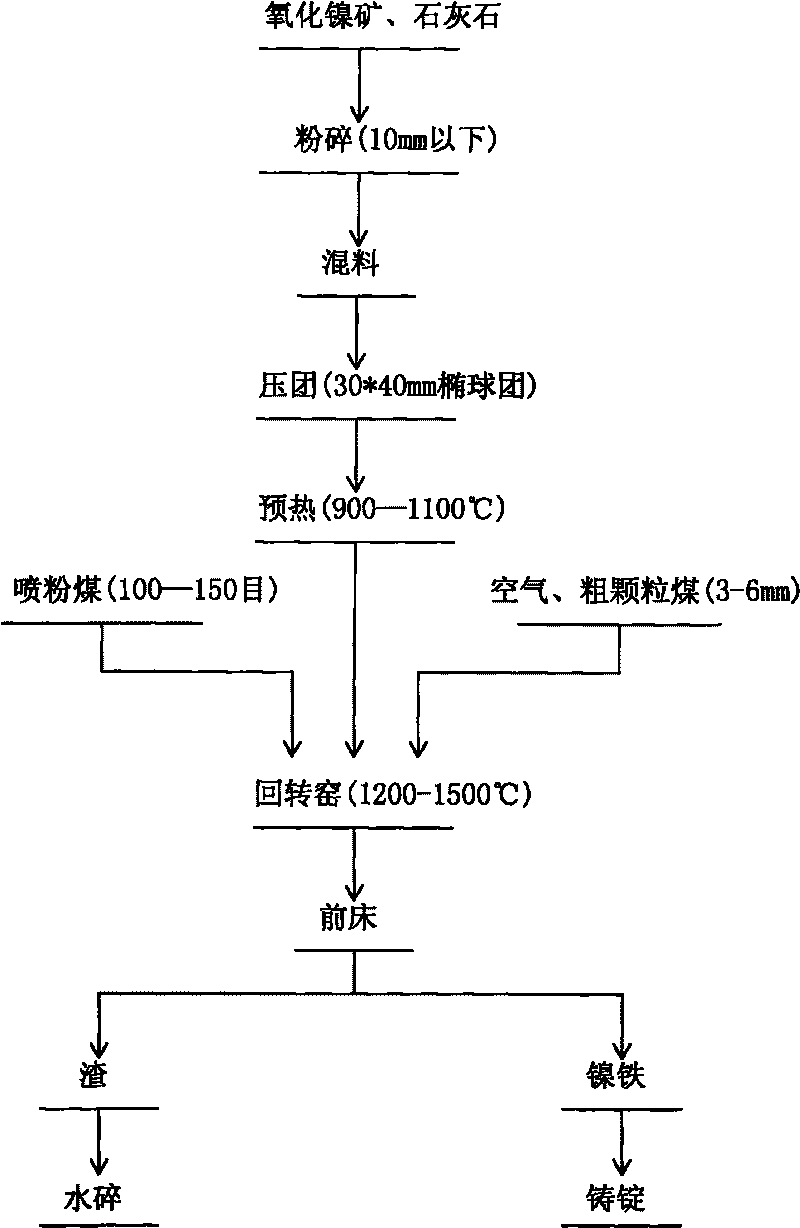

[0031] attached figure 1 Represent a kind of technological process of smelting ferronickel with nickel oxide ore, complete according to the following steps:

[0032] ① Nickel oxide ore batching processing

[0033] First, limestone is added to the nickel oxide ore, and the amount of limestone is 2-5% of the weight of the nickel oxide ore; it is pulverized into a powder with a particle size below 10mm by the pulverizer 22; it is fully stirred and mixed by the mixer 23 and then sent to the roller press Machine 24 presses pellets into 30*40mm elliptical pellets;

[0034] ②Heat drying

[0035] The obtained ellipsoidal pellets are lifted to the preheating furnace 1, preheated in the high-temperature waste heat of the preheating furnace 900-1100°C, and dried, and there is an exhaust pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com