Treatment process for manufacturing tobacco cut stems by tobacco stem

A treatment process and technology for tobacco stems, which is applied in the field of treatment process for processing tobacco stems into shredded tobacco stems, and can solve the problems of cleaning water pollution, pollution, volatilization of beneficial substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

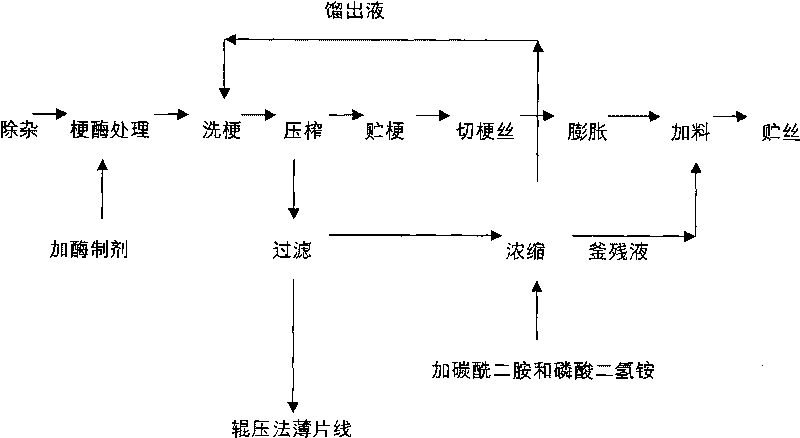

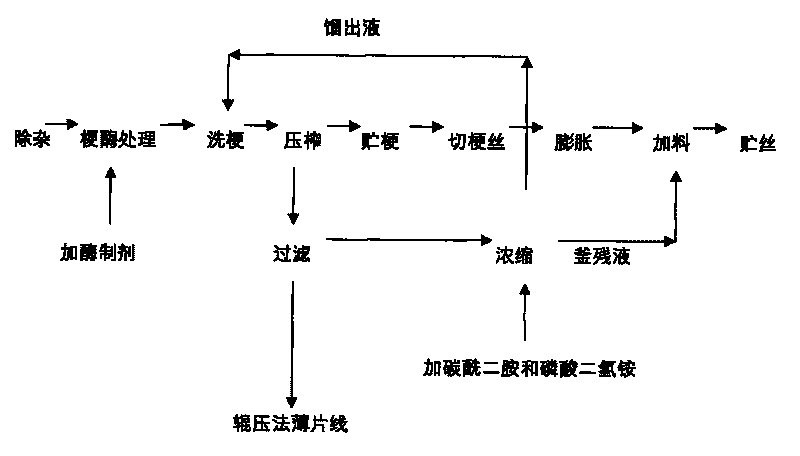

Method used

Image

Examples

Embodiment 1

[0032] The tobacco stems were sampled and analyzed, and the results are shown in Table 1.

[0033] Table 1 Chemical analysis of raw materials for production Unit: %

[0034] reducing sugar

16.0

12.0

2.3

16.0

4.5

[0035] The analysis results of the raw materials showed that the cellulose and starch contents in the raw materials, which are not conducive to the sensory quality of cigarettes, were relatively high.

[0036] Weigh 100kg of tobacco stems, add 1.3kg of amylase with an activity of 2000u / g, 0.6kg of glucoamylase with an activity of 10000u / g, and 1.2kg of cellulase with an activity of 4000u / g, and keep the enzymatic conditions as follows: 50°C, moisture 60%, 2 hours, and adjust the pH to 5 with buffer. After the enzymatic hydrolysis is completed, heat at 100°C and keep for 30 minutes to inactivate.

[0037] The enzymatic tobacco stems are sent to the stem washing pool, washed ...

Embodiment 2

[0045] The tobacco stems were sampled and analyzed, and the results are shown in Table 2.

[0046] Table 2 Chemical Analysis of Tobacco Stems Unit: %

[0047] reducing sugar

10.0

11.9

1.9

3.4

15.9

[0048] The raw material analysis results showed that the pectin and cellulose content in the raw material, which is not conducive to the sensory quality of cigarettes, was relatively high.

[0049]Weigh 100kg of tobacco stems and add 0.5kg of pectinase with an activity of 20000u / g, and 1.19kg of cellulase with an activity of 4000u / g. And maintain the enzymatic conditions as follows: temperature 50°C, moisture 35%, time 4h, buffer solution to adjust pH to 4.0. After the enzymatic hydrolysis is completed, heat at 90°C and keep for 30 minutes to inactivate.

[0050] Put the enzymatic tobacco stems into the stem washing tank, wash them with 1200kg of water at 50°C for 30 minutes, squeeze them...

Embodiment 3

[0058] The tobacco stems were sampled and analyzed, and the results are shown in Table 3.

[0059] Table 3 Chemical analysis table of raw materials for production Unit: %

[0060] reducing sugar

protein

starch

pectin

11.5

5.9

5.9

10.7

2.9

[0061] The results of raw material analysis showed that the content of protein and starch in the raw material, which is not conducive to the sensory quality of cigarettes, was relatively high.

[0062] Add 0.72kg of protease with an activity of 10000u / g to 100kg of tobacco stem raw material, and 1.33kg of amylase with an activity of 2000u / g. And maintain the enzymatic conditions as follows: temperature 70° C., moisture 40%, 3 hours, and buffer solution to adjust the pH value to 6.0. After the enzymatic hydrolysis is completed, heat at 100°C and keep for 30 minutes to inactivate.

[0063] Put the enzymatic tobacco stems into the stem washing tank, wash them with 1500kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com