Method for crudely extracting saccharomyces cerevisiae glutathione

A technology of glutathione and brewer's yeast, which is applied in the field of glutathione extraction and brewer's yeast glutathione extraction, can solve the problems of mercury content easily exceeding the standard, high cost, and large pollution, so as to improve the extraction rate , reduce the amount of use, improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

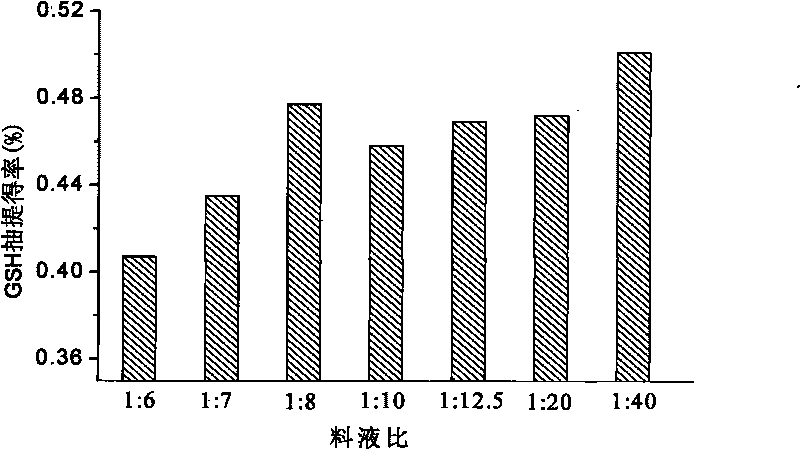

[0030] The optimization of embodiment 1 solid-liquid ratio:

[0031] Take 10ml of deionized water each, according to the ratio of material to liquid (dry yeast g / ml of deionized water) 1:6, 1:7, 1:8, 1:10, 1:12.5, 1:20, 1:40 Add dry beer yeast, mix well, adjust the pH to 3.5 with phosphoric acid, stir and heat at 69-72°C for 14min, put in the refrigerator and cool to room temperature and centrifuge (6000r / min, 12min), measure the supernatant in 9 different conditions The concentration of GSH was used to calculate the extraction yield of GSH. See figure 1 As shown, the experimental results show that the maximum GSH extraction yield is 0.5013% when the solid-liquid ratio is 1:40, followed by 0.4766% when the ratio is 1:8. The extraction rate of the former is 5.18% higher than that of the latter, but the amount of deionized water used is 5 times that of the latter. In actual production, considering the comprehensive reduction of labor intensity, water saving and energy saving, ...

Embodiment 2

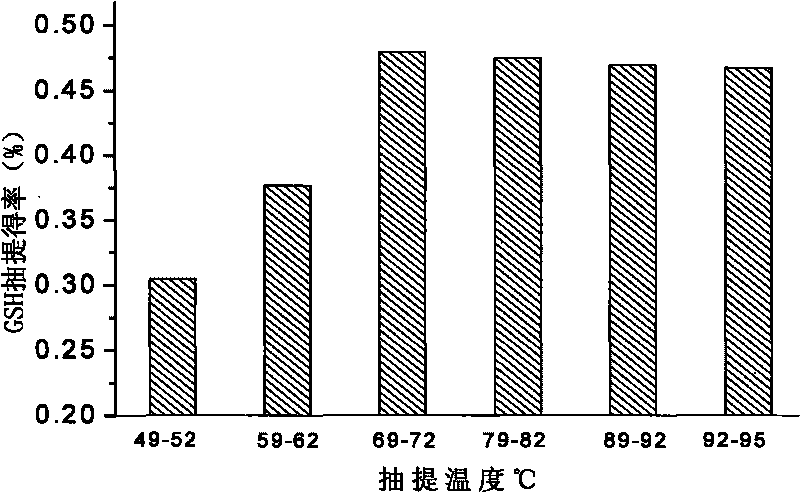

[0032] The optimization of embodiment 2 extraction temperature:

[0033] Take 10ml of deionized water, add 1.25g of brewer's dry yeast, mix well, adjust the pH to 3.5 with phosphoric acid, and set the pH in 5 different temperature ranges (49-52, 59-62, 69-72, 79-82, 89- 92,92-95°C), stirred and heated for 12min, placed in the refrigerator to cool to room temperature and centrifuged (6000r / min, 12min), measured the concentration of GSH in the supernatant under 5 different conditions, and calculated the extraction yield. See figure 2 As shown, the experimental results show that as the temperature increases, the GSH extraction first increases and then decreases, and the maximum is 0.48% at 69-72°C. When the temperature is low, the permeability of the cell membrane is poor, and GSH is not completely released from the membrane; if the temperature is too high, the permeability of the cell membrane is too high, and the release of oxidative substances in the cell will also lead to t...

Embodiment 3

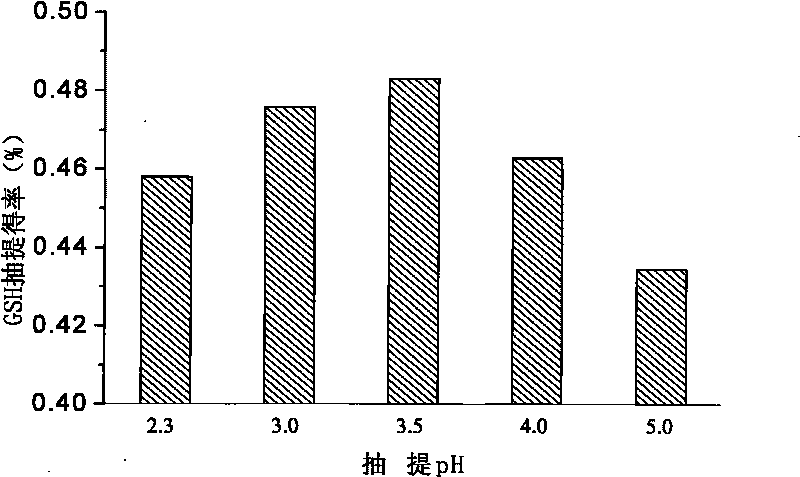

[0034] The optimization of embodiment 3 extraction pH:

[0035] Take 10ml of deionized water, add 1.25g of beer dry yeast, mix well, adjust pH to 2.3, 3.0, 3.5, 4.0, 5.0 with phosphoric acid respectively, stir and heat for 12min at 69-72°C, place in refrigerator to cool to room temperature Centrifuge (6000r / min, 12min), measure the concentration of GSH in the supernatant under 4 different conditions, and calculate the extraction yield. See image 3 As shown, the experimental results show that with the increase of pH, the GSH extraction first increases and then decreases, and the maximum value is 0.483% at pH 3.5. When the pH is low, the permeability of the cell membrane is increased, or even destroyed, and the oxidative substances in the membrane are released, which will lead to the oxidation of GSH; when the pH is high, the oxidation of GSH is also increased, so pH 3.5 is selected as the best extraction pH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com