Preparation method of bismuth-containing eulytite bismuth silicate crystals

A technology of sphalerite and bismuth silicate, which is applied in the field of silicate crystal preparation, can solve the problem that it is difficult to obtain high-purity bismuth silicate nanopowder, which is not suitable for mass production of bismuth silicate nanopowder, and the disadvantage of bismuth silicate and other problems, to achieve the effect of low price, less impurity phase, and reduce the generation of impurity phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

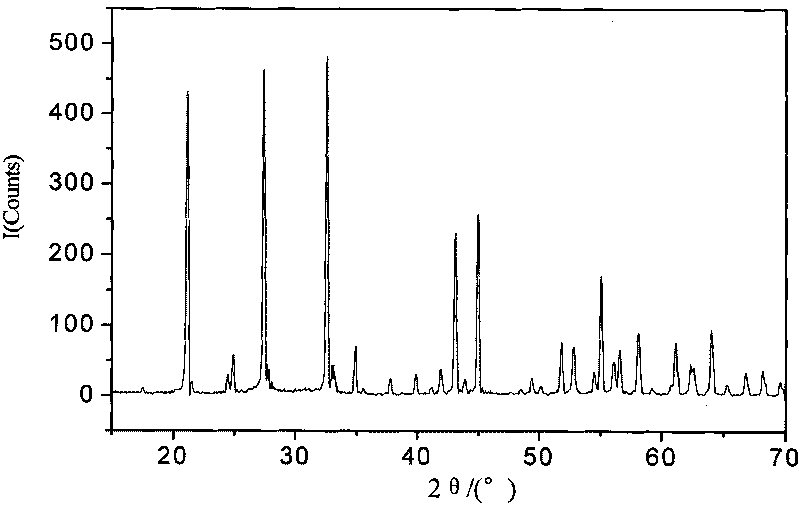

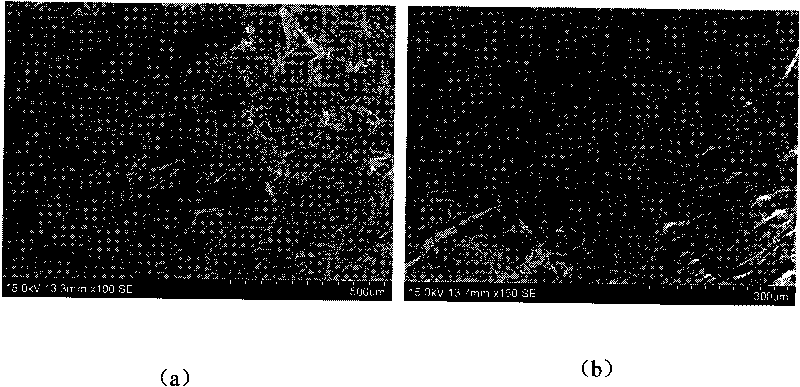

Embodiment 1

[0016] Example 1, first, after cleaning and drying the quartz glass, put it into a ball mill jar and grind it to 300 mesh to make quartz glass powder; then according to the molar ratio Bi 2 o 3 : SiO 2 =1: 1 mix bismuth trioxide powder (content is 99.99%) and quartz glass powder and put into agate emulsion ball mill jar and ball mill for 30min to obtain batch; batch batch is put into high-purity alumina crucible, and then Put the crucible with the batch material into the muffle furnace, and fire it according to the following process: from room temperature to 550°C at a heating rate of 5°C / min and keep it warm for 30 minutes; then at a heating rate of 10°C / min. 550 ° C to 900 ° C and keep it warm for 6 hours; then quickly take out the crucible from the muffle furnace and put it into flowing water, let the sample cool to room temperature at 400 ° C / min, take out the water-quenched sample after cooling, and finally , the sample was dried and ball-milled to obtain bismuth-cont...

Embodiment 2

[0018] Example 2, first, after cleaning and drying the quartz glass, put it into a ball mill jar and grind it to 300 mesh to make quartz glass powder; then, according to the molar ratio Bi 2 o 3 : SiO 2 =1: 1 mixes bismuth trioxide powder (content is 99.99%) and quartz glass powder and puts into agate emulsion ball mill jar and ball mills for 30min to obtain batch; Put the crucible with batch materials into the muffle furnace, and fire it according to the following process system: raise the temperature from room temperature to 550°C at a heating rate of 5°C / min and keep it for 30 minutes; then heat it at a heating rate of 10°C / min Rise from 550°C to 920°C and keep it warm for 12 hours; then quickly take out the crucible from the muffle furnace and put it into flowing water, cool the sample to room temperature at 400°C / min, take out the water-quenched sample after cooling, Finally, the sample was dried and ball-milled to obtain bismuth-containing bismuth bismuth silicate (Bi ...

Embodiment 3

[0020] Example 3, first, after cleaning and drying the quartz glass, put it into a ball mill jar and mill it to 300 mesh to make quartz glass powder; then according to the molar ratio Bi 2 o 3 : SiO 2 = 1: 1 mixes bismuth trioxide powder (content is 99.99%) and quartz glass powder and puts into agate emulsion ball mill jar and ball mills for 40min to obtain batch; Put the crucible with the batch material into the muffle furnace, and fire it according to the following process system: raise the temperature from room temperature to 550°C at a heating rate of 5°C / min and keep it for 30 minutes; then heat it at a heating rate of 12°C / min Rise from 550°C to 890°C and keep it warm for 16 hours; then quickly take out the crucible from the muffle furnace and put it into flowing water, cool the sample to room temperature at 400°C / min, take out the water-quenched sample after cooling, Finally, the sample was dried and ball-milled to obtain bismuth-containing bismuth bismuth silicate (B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com