Preparation method of Bi2O3 polycrystal

A technology of melting and bismuth oxide, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth, can solve the problems of unsatisfactory industrialized large-scale production, high raw material purity requirements, and complicated preparation processes, and achieve considerable economic benefits. and social benefits, low raw material requirements, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

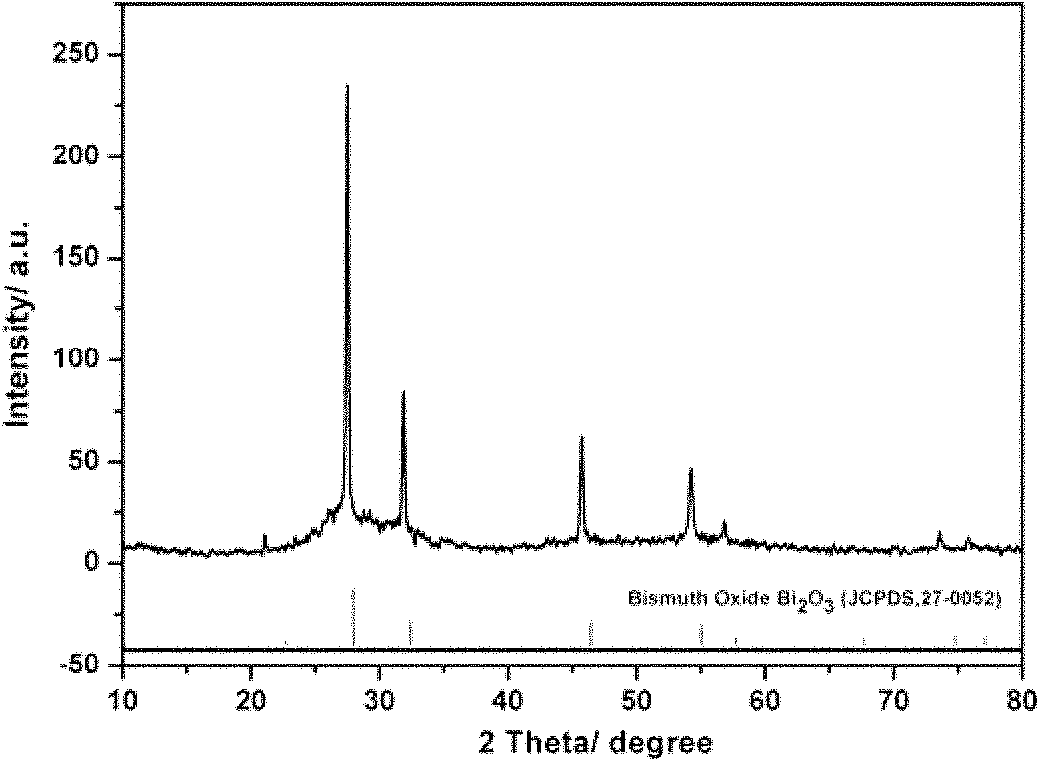

Image

Examples

Embodiment 1

[0014] Step 1: Preparation of Bismuth Oxide Glass Melt

[0015] First, 83% of the Bi 2 o 3 and 17% SiO 2 Mix evenly to form a batch material; secondly, add the batch material to a corundum crucible with a cover at 1100 °C, and heat up to the melting temperature at a heating rate of 20 °C / min for melting to form a bismuth oxide high-temperature glass melt, and the melting temperature is 1200°C, and keep it at the melting temperature for 2 hours. During the melting process, use a corundum stirring rod to stir the bismuth oxide high-temperature glass melt for 1 minute every hour; then, cool the uniformly melted bismuth oxide high-temperature glass melt To 900°C, take out the crucible and pour the melt into a heat-resistant steel mold, put it into an annealing furnace at 400°C after the melt is solidified, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain a bismuth oxide glass melt;

[0016] Added SiO 2 Introduced through industrial quartz sand...

Embodiment 2

[0021] Step 1: Preparation of Bismuth Oxide Glass Melt

[0022] First, divide 80% Bi by mass fraction 2 o 3 and 20% SiO 2 Mix evenly to form a batch material; secondly, add the batch material to a corundum crucible with a cover at 1100 °C, and heat up to the melting temperature at a heating rate of 20 °C / min for melting to form a bismuth oxide high-temperature glass melt, and the melting temperature is 1250°C, and keep it at the melting temperature for 4 hours. During the melting process, use a corundum stirring rod to stir the bismuth oxide high-temperature glass melt for 1 minute every hour; then, cool the uniformly melted bismuth oxide high-temperature glass melt To 900°C, take out the crucible and pour the melt into a heat-resistant steel mold, put it into an annealing furnace at 400°C after the melt is solidified, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain a bismuth oxide glass melt;

[0023] Added SiO 2 Introduced through indus...

Embodiment 3

[0027] Step 1: Preparation of Bismuth Oxide Glass Melt

[0028] First, 81% of the Bi 2 o 3 and 19% SiO 2 Mix evenly to form a batch material; secondly, add the batch material to a corundum crucible with a cover at 1100 °C, and heat up to the melting temperature at a heating rate of 20 °C / min for melting to form a bismuth oxide high-temperature glass melt, and the melting temperature is 1230°C, and keep it at the melting temperature for 3 hours. During the melting process, use a corundum stirring rod to stir the bismuth oxide high-temperature glass melt for 1 minute every hour; then, cool the uniformly melted bismuth oxide high-temperature glass melt To 900°C, take out the crucible and pour the melt into a heat-resistant steel mold, put it into an annealing furnace at 400°C after the melt is solidified, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain a bismuth oxide glass melt;

[0029] Added SiO 2 Introduced through industrial quartz sand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com