Pork tenderizer containing calcium

A tenderizer and pork technology, applied in application, food preparation, food science, etc., can solve problems affecting meat quality, calcium-phosphorus ratio imbalance, and reduce shear force, etc., to achieve obvious tenderization effect, safe and reliable ingredients, The effect of enhancing water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in more detail below:

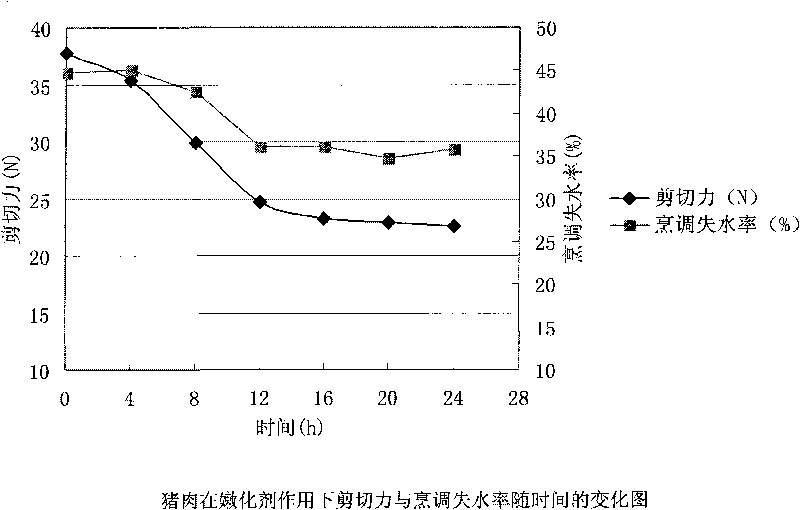

[0013] In this embodiment, sodium chloride is 4.0wt%, calcium chloride is 2.5wt%, and papain is 0.025wt%, wherein the unit enzyme activity of the papain is 200,000 U / g, and the remainder is water. Add the tenderizer in the above ratio and mix evenly to make a solution with the above concentration. Add 50g of tenderizer solution per kilogram of pork, that is, the amount of tenderizer solution is 5% of the weight of the meat, and inject it evenly into the meat. , and then carry out continuous rolling and massaging for 30 minutes, and finally place it at 4°C for 24 hours. With reference to the accompanying drawings, the shearing force of the meat is reduced by about 40%, and the cooking water loss rate of the meat is reduced from 44.8% to 35.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com