Method for preparing lead sulfate and mangano-manganic oxide materials from galena and pyrolusite

A manganese tetroxide material, pyrolusite technology, applied in the directions of lead sulfate, manganese oxide/manganese hydroxide, etc., can solve the problems of human health, environmental damage, high energy consumption, and achieve low cost, high purity and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

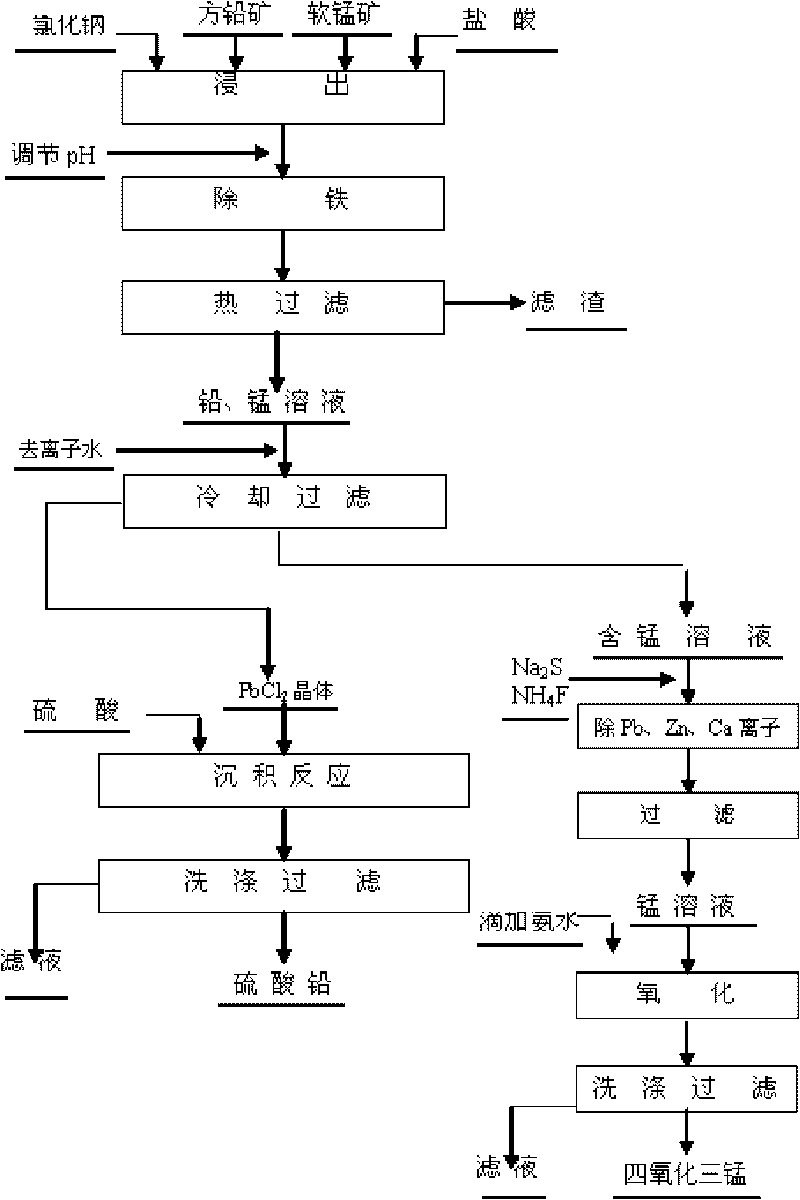

Method used

Image

Examples

Embodiment 1

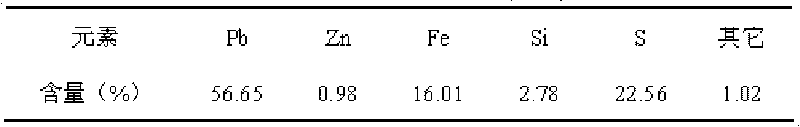

[0033] The galena concentrate from a lead-zinc mine in Yunnan is used, and the -0.074mm particle size accounts for 84.3%. The chemical composition is shown in Table 1.

[0034] Table 1 Galena Concentrate Chemical Composition (wt%)

[0035]

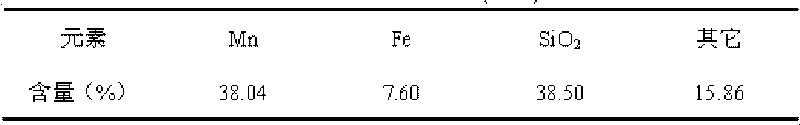

[0036] The -0.074mm particle size of pyrolusite accounts for 95.4%. The elemental analysis results of pyrolusite are listed in Table 2.

[0037] Table 2 pyrolusite elemental analysis (wt%)

[0038]

[0039] 1) The leaching process conditions are: mix galena, pyrolusite, water, and sodium chloride in a weight ratio of 1:1.6:4:2, and add a total amount of 0.375mol hydrochloric acid in stages in every liter of mixed solution; the reaction temperature The temperature is 75°C, the reaction time is 50 minutes, and the rotation speed of the stirrer is 500 rpm. The hydrochloric acid adopts the mode of adding in portions, and 80% hydrochloric acid by weight is added at the beginning of the reaction, and the remaining 20% is added after th...

Embodiment 2

[0053] The galena concentrate from a lead-zinc mine in Guangdong was used, and the -0.074mm particle size accounted for 86.2%. The chemical composition is shown in Table 5.

[0054] Table 5 Galena Concentrate Chemical Composition (wt%)

[0055]

[0056] The particle size of -0.074mm in pyrolusite accounts for 96.1%. The elemental analysis results of pyrolusite are listed in Table 6.

[0057] Table 6 pyrolusite elemental analysis (wt%)

[0058]

[0059] 1) The leaching process conditions are: galena, pyrolusite, water, and sodium chloride are mixed in a weight ratio of 1: 1.6: 4: 2, and the hydrochloric acid that a total amount is 0.375mol is added in stages in every liter of mixed solution; the reaction temperature is 80°C, the reaction time is 60 minutes, and the rotation speed of the stirrer is 600 rpm. The hydrochloric acid adopts the mode of adding in portions, and 80% hydrochloric acid by weight is added at the beginning of the reaction, and the remaining 20% is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com