Method for synthesizing unsaturated polyester

A synthetic method and unsaturated technology, applied in the field of synthesizing unsaturated polyester, can solve problems such as complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

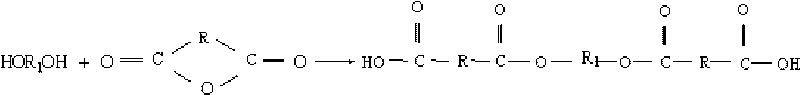

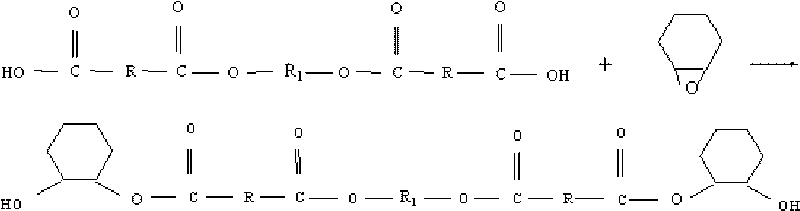

Method used

Image

Examples

Embodiment 1

[0028] Add 3.016g of cyclohexanediol, 15.392g of phthalic anhydride, 10.192g of maleic anhydride, 0.135g of catalyst cetyltrimethylammonium bromide, and 9.537g of solvent toluene into the reactor, start stirring, and Heating to raise the temperature, condensing and refluxing, reacting the material at 120°C for 1.5h, then cooling down to 90°C, adding 25.48g of epoxycyclohexane dropwise, and reacting for another 5h, adding 0.01wt% of the total weight of the material as a polymerization inhibitor p-benzene Diphenol, vacuumize to 0.050MPa to remove solvent, then add diluent styrene, cool and discharge.

[0029] Synthetic resin products meet the following technical requirements: 1) The appearance is light brown yellow transparent viscous liquid; 2) The acid value is 35.28mgKOH / g; 3) The relative molecular weight is about 1200;

[0030] The unsaturated polyester has a tensile strength of 88 MPa, an elongation at break of 3.2, and a mechanical property retention rate of 83% after the...

Embodiment 2

[0032] Phthalic anhydride is reduced to 5.096g by glutaric anhydride 5.928g and malonic anhydride 8.944g mixture instead of maleic anhydride quality; Catalyst trimethyl benzyl ammonium chloride 0.13g, solvent uses xylene; The amount of methoxyphenol added is equivalent to 0.1wt% of the total weight of the material; the solvent is removed by vacuuming at 0.099 MPa; the others are the same as in Example 1.

[0033] Synthetic resin products meet the following technical requirements: 1) The appearance is light brown yellow transparent viscous liquid; 2) The acid value is 40.04mgKOH / g; 3) The relative molecular weight is about 1100.

[0034] The unsaturated polyester has a tensile strength of 80 MPa, an elongation at break of 3.0, and a mechanical property retention rate of 80% after thermo-oxidative aging.

Embodiment 3

[0036] The quality of maleic anhydride is increased to 15.249g, and phthalic anhydride is replaced by hexahydrophthalic anhydride, and the quality is 8.008g; Solvent; Others are with embodiment 1.

[0037] The synthetic resin meets the following technical requirements: 1) The appearance is a brownish-yellow transparent viscous liquid; 2) The acid value is 34.7mgKOH / g; 3) The relative molecular weight is about 1300.

[0038] The unsaturated polyester has a tensile strength of 82MPa, an elongation at break of 3.1, and a mechanical property retention rate of 84% after thermo-oxidative aging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com