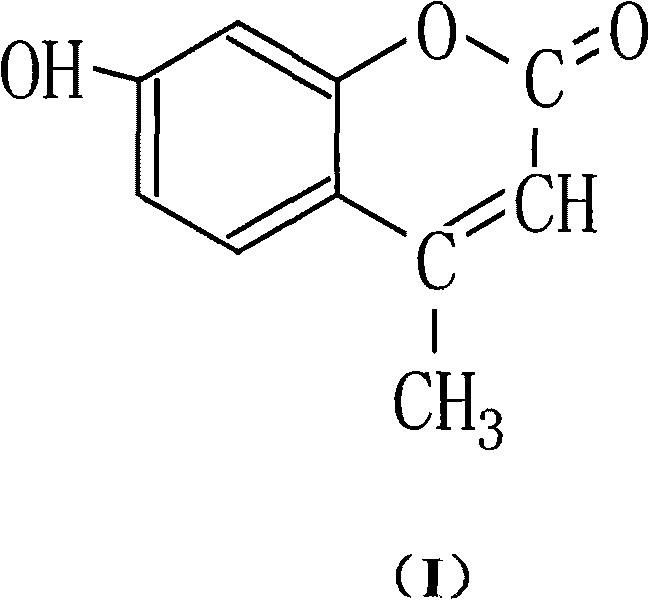

Purifying method of laser dye cumarin-4

A technology of laser dye and purification method, which is applied in the field of purification of laser dye coumarin-4, which can solve the problems of poor economy, low purity of laser dye coumarin-4, and short dye life, so as to prolong life and improve purity , Improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 0.1 mol of resorcinol was dissolved in 0.1 mol of newly distilled ethyl acetoacetate to make a solution, and this solution was added dropwise to 100ml of concentrated sulfuric acid cooled to 0°C in an ice-salt bath with stirring, The reaction temperature is controlled below 10°C, and the dropwise addition is completed in 2 hours; continue to stir for half an hour, and then inject the reaction mixture into a 1000g ice-water mixture. 3×5ml Wash the precipitate with cooling water, filter it with suction and dry it in an oven to obtain the crude product of laser dye coumarin-4, and then purify:

[0023] (1). The laser dye coumarin-4 crude product is dissolved in a 5% sodium hydroxide aqueous solution at a temperature of 30°C, then the solution is cooled to room temperature, and the filtered filtrate is used for subsequent use;

[0024] (2). Adding dilute sulfuric acid to the filtrate at a temperature of 0 to -5°C to adjust the pH to 6, and washing, suction filtering, and dr...

Embodiment 2

[0029] The preparation of the crude product of laser dye coumarin-4 is the same as embodiment 1, and its purification steps are:

[0030] (1). The laser dye coumarin-4 crude product is dissolved in a 5% sodium hydroxide aqueous solution at a temperature of 40° C., then the solution is cooled to room temperature, and the filtered filtrate is set aside;

[0031] (2). Adding dilute sulfuric acid to the filtrate at a temperature of 0 to -5°C to adjust the pH to 6, and washing, suction filtering, and drying the filtered precipitate to obtain the light gray laser dye coumarin-4;

[0032] (3). Add the light gray laser dye coumarin-4 to 95% ethanol, heat and reflux until the light gray laser dye coumarin-4 is completely dissolved, and then add activated carbon to reflux for decolorization;

[0033] (4). Activated carbon is filtered out of the decolorized solution, the filtrate is left standing in a cold water bath, and the precipitated crystals are filtered and dried to obtain white l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com