Dynamic preparation device for standard gas of solid-phase or liquid-phase compounds and application thereof

A preparation device and standard gas technology, applied in the preparation of test samples, chemical/physical processes, mixing methods, etc., can solve the problems of high instrument cost, difficulty in accurately reaching more than 2 orders of magnitude, high instrument requirements, etc., to achieve expansion Effect of Concentration Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

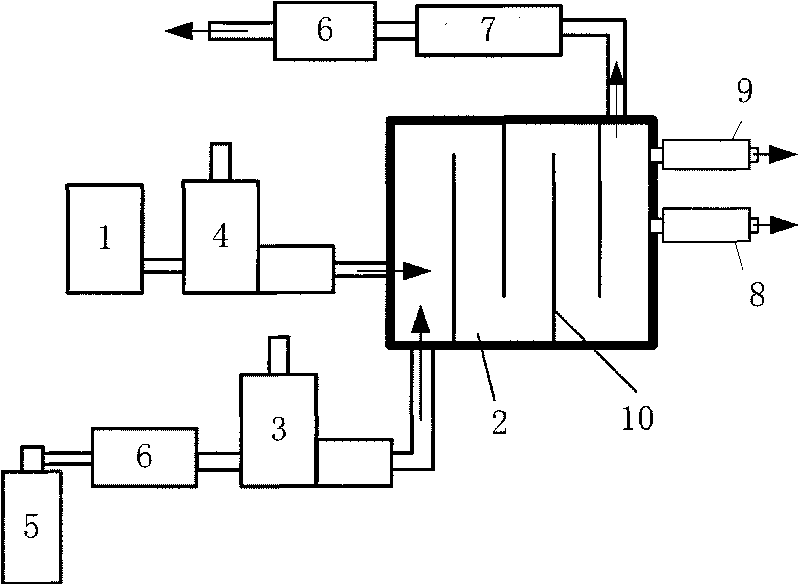

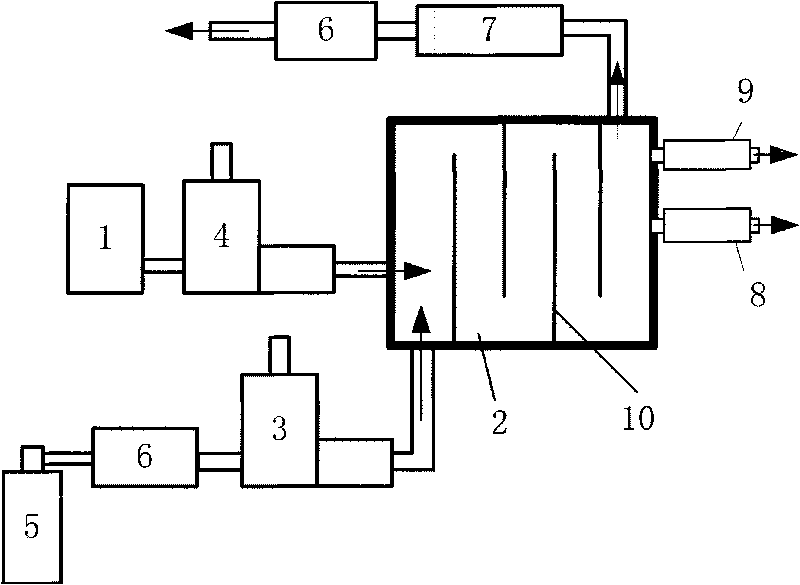

[0017] The preparation process and instrument structure schematic diagram of standard concentration gas preparation method among the present invention are as attached figure 1 shown. A dynamic preparation device for a solid or liquid compound standard gas, comprising a sample pool 1, a constant temperature evaporation pool 2, a gas flow controller 3, a liquid flow controller 4, a dilution gas source 5, and the sample pool 1 passes through a pipeline through a liquid The flow controller 4 is connected to the sample solution inlet provided on the side wall of the constant temperature evaporation pool 2, and a dilution gas inlet is provided on the wall of the constant temperature evaporation pool 2 near the sample solution inlet, and the dilution gas source 5 is controlled by the gas flow through the pipeline. The device 3 is connected to the dilution gas inlet; a sampling port and an exhaust gas port are arranged on the other side wall of the constant temperature evaporation poo...

Embodiment 1

[0055] Embodiment 1, preparation single-component compound concentration

[0056] In this example, the standard gas of pyrene, a low-volatile aromatic hydrocarbon substance, was prepared, and a solution with a concentration of 0.01 mol / L was prepared using n-hexane as a solvent.

[0057] Set the temperature of the constant temperature evaporation pool to 200°C. Stable for 1 hour.

[0058] Take 100ml of sample solution and store it in the sample solution bottle, turn on the micro flow rate controller, and adjust the liquid flow rate to 0.11ml / min. Accurately control the dilution gas flow rate to 2.7L / min. After stabilizing for 10 minutes, sample the gas with standard concentration.

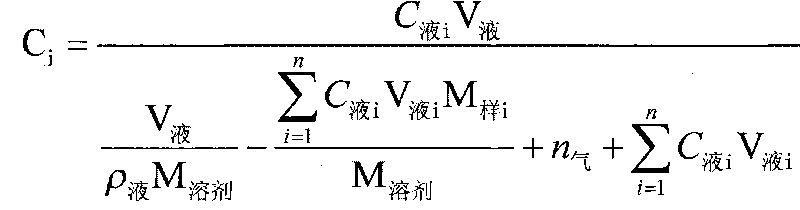

[0059] Sample gas concentration calculation:

[0060] 1. Calculate with accurate formula, for nitrogen, a=0.137Pa*m 6 / mol 2 , b=0.0000387m 3 / mol, the gas flow rate is 2.7L / min, the pressure of the dilution gas before entering the evaporation pool is taken as the standard atmospheric pressu...

Embodiment 2

[0064] Embodiment 2, preparation multi-component compound gas

[0065] This method prepares the mixed gas of pyrene and trichlorophenol, which are difficult to volatile aromatic hydrocarbons, and uses n-hexane as a solvent. First, a mixed solution of pyrene and trichlorophenol with a concentration of 0.01mol / L is prepared.

[0066] Set the temperature of the constant temperature evaporation pool to 200°C and keep it stable for 1 hour.

[0067] Take 100lm of sample solution and store it in the sample solution bottle, turn on the micro flow rate controller, and adjust the liquid flow rate to 1ml / min. Accurately control the dilution gas flow rate to 2L / min. After stabilizing for 20 minutes, the standard concentration gas was obtained by sampling.

[0068] Sample gas concentration calculation:

[0069] 1. Calculate with accurate formula, for nitrogen, a=0.137Pa m 6 / mol 2 , b=0.0000387m 3 / mol, the gas flow rate is 2L / min, the pressure of the dilution gas before entering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com