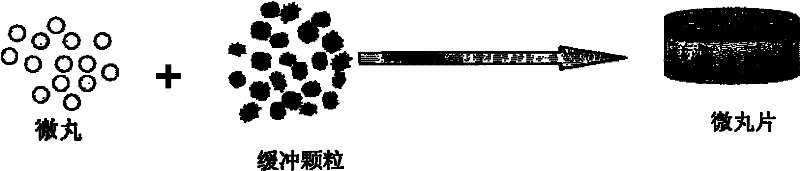

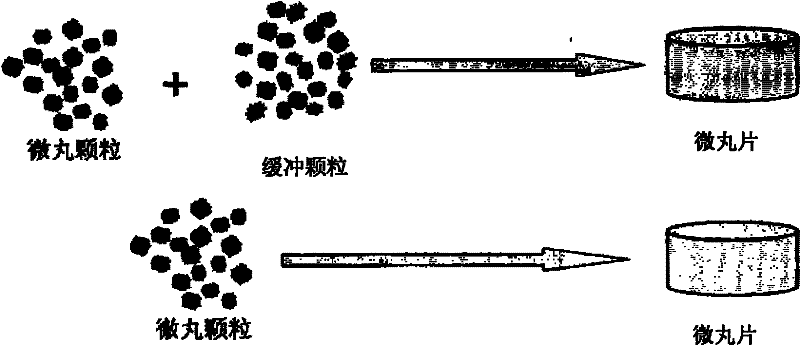

Method for preparing pellet tablets

A technology of micropills and micropills, which is applied in the field of preparation of micropills, can solve the problems that are difficult to do, the tablet cannot be divided into doses, and the complex preparation process has high efficiency and low cost of tablets, so as to reduce fluidity, Uniform quality and drug content, suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

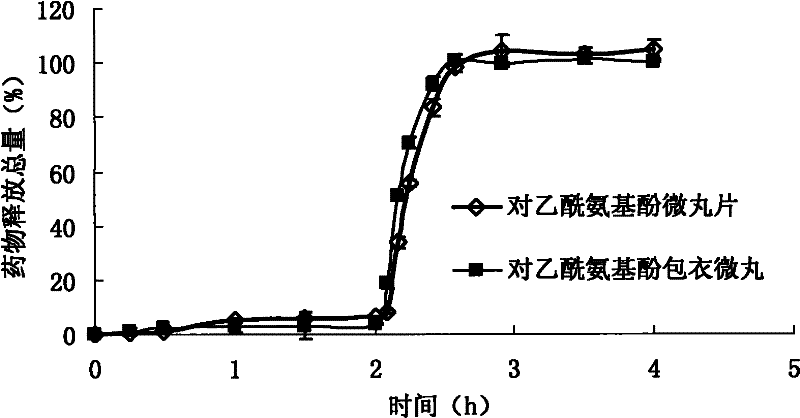

[0035] Embodiment 1: the preparation of acetaminophen pellets

[0036] Include the following steps:

[0037] 1. Preparation of acetaminophen-coated pellets

[0038] Weigh each component material according to the following formula:

[0039] 200-300μm particle size paracetamol pellets 600g

[0040] Eudragit FS 30D (Evonik, Germany) 300g

[0041] Eudragit L 30D-55 (Evonik, Germany) 300g

[0042] Glyceryl monostearate (anti-sticking agent, Shantou Xilong Chemical) 15g

[0043] Triethyl citrate (plasticizer, Beijing Jingqiu Chemical) 15g

[0044] Pure water 300g

[0045]Total 1530g

[0046] Dissolve Eudragit FS 30D, Eudragit L 30D-55, glyceryl monostearate and triethyl citrate in pure water to prepare a coating liquid; put the acetaminophen pellets in a fluidized bed; The coating solution is placed at the liquid inlet end to coat the paracetamol pellets to obtain paracetamol coated pellets with the same particle size.

[0047] 2. Preparation of Micropellet Particles

[...

Embodiment 2

[0068] Embodiment 2: the preparation of doxycycline hydrochloride pellets

[0069] Include the following steps:

[0070] 1. Preparation of doxycycline hydrochloride coated pellets

[0071] Weigh each component material according to the following formula:

[0072] 300-450μm particle size doxycycline hydrochloride pellets 400g

[0073] Hypromellose phthalate HP55 (coating material, Shin-Etsu Corporation, Japan) 60g

[0074] Hypromellose E15 (pore forming agent, Colorcon) 6g

[0075] Triethyl citrate (plasticizer, Beijing Jingqiu Chemical) 6g

[0076] 95% ethanol (Tianjin Hongyan Chemical Reagent Factory) 720g

[0077] Pure water 180g

[0078] Total 1372g

[0079] Put doxycycline hydrochloride pellets into a fluidized bed, and prepare hydroxypropylmethylcellulose phthalate HP55, hydroxypropylmethylcellulose E15, triethyl citrate, and 95% alcohol The coating solution is placed at the liquid inlet end to coat the doxycycline hydrochloride pellets to obtain coated pellets ...

Embodiment 3

[0104] The preparation of embodiment 3 aspirin pellets

[0105] Include the following steps:

[0106] 1. Preparation of aspirin-coated pellets

[0107] Weigh each component material according to the following formula:

[0108] 50-150μm particle size aspirin pellets 600g

[0109] Ethyl cellulose (coating material, Tianjin Aileyi Company) 60g

[0110] Triethyl citrate (plasticizer, Beijing Jingqiu Chemical) 24g

[0111] Tween 80 (plasticizer, Beijing Haidian Huiyou Fine Chemical Industry) 10g

[0112] 95% ethanol (Tianjin Hongyan Chemical Reagent Factory) 200g

[0113] Pure water 300g

[0114] Total 1194g

[0115] Put the aspirin pellets in the fluidized bed, disperse the ethyl cellulose evenly in ethanol, dissolve other materials in pure water, slowly mix the ethanol solution and the aqueous solution, and stir for 30 minutes with a homogeneous emulsifier while mixing, to obtain The coating solution is placed at the liquid inlet end to coat the aspirin pellets to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com